Blast furnace banking method

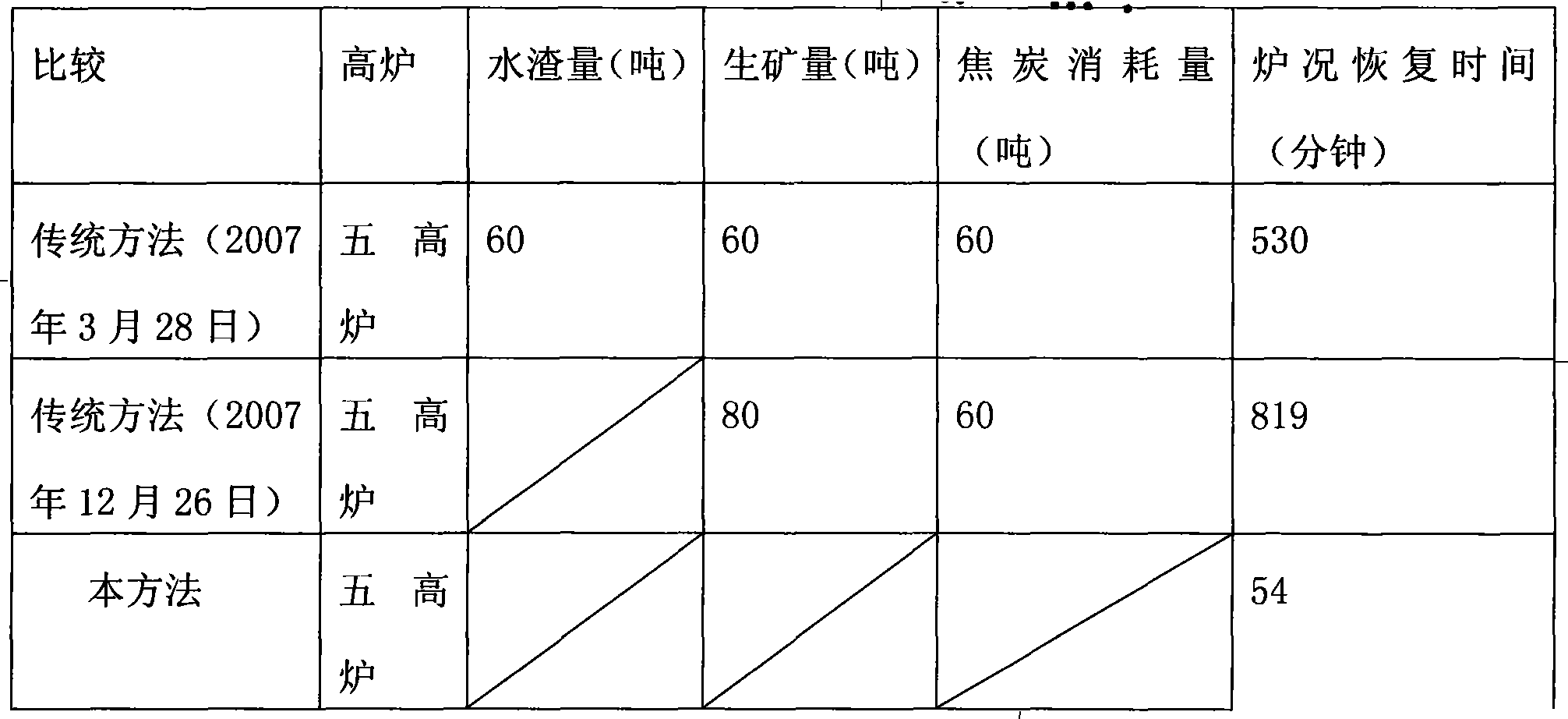

A technology of braising furnace and blast furnace, which is applied in the field of braising furnace to reduce the temperature of the top of blast furnace. It can solve the problems of prolonging the time for blast furnace to return to normal, affecting the quality of molten iron, and difficulty in restoring furnace conditions, so as to improve the technical and economic indicators of blast furnace and the quality of molten iron. Guaranteed, good braising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0019] Concrete embodiment: such as heavy steel No. 5 blast furnace (effective volume 1200m 3 ) The furnace top chute protection is faulty and needs to be overhauled. This maintenance needs to open the avenue door, and personnel enter the furnace to replace the chute protection plate. In order to ensure the temperature requirements for entering the furnace during maintenance, the invention is used to simmer the blast furnace to reduce the furnace top temperature, which meets the temperature requirements for personnel entering the furnace without affecting the construction progress. The specific implementation is as follows:

[0020] 1. Formulate a detailed shutdown and cooling material plan

[0021] 1) First add 9.4 tons of wind coke, and then add 4.7 tons after 3 batches of raw material. Note that the coke contains 3.5% water.

[0022] Ingredients:

[0023] mine batch

Jiao batch

Qijiang Mine

Australian mine

add ball

S1

S3

26 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com