Method for preparing petroleum naphthalene by using C+10 heavy aromatic hydrocarbon as raw material

A technology for heavy aromatics and petroleum naphthalene, applied in the direction of isomerization hydrocarbon production, organic chemistry, etc., can solve the problems of serious environmental pollution, long process flow, high cost, etc., and achieve the effect of easy source of raw materials, few process steps, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

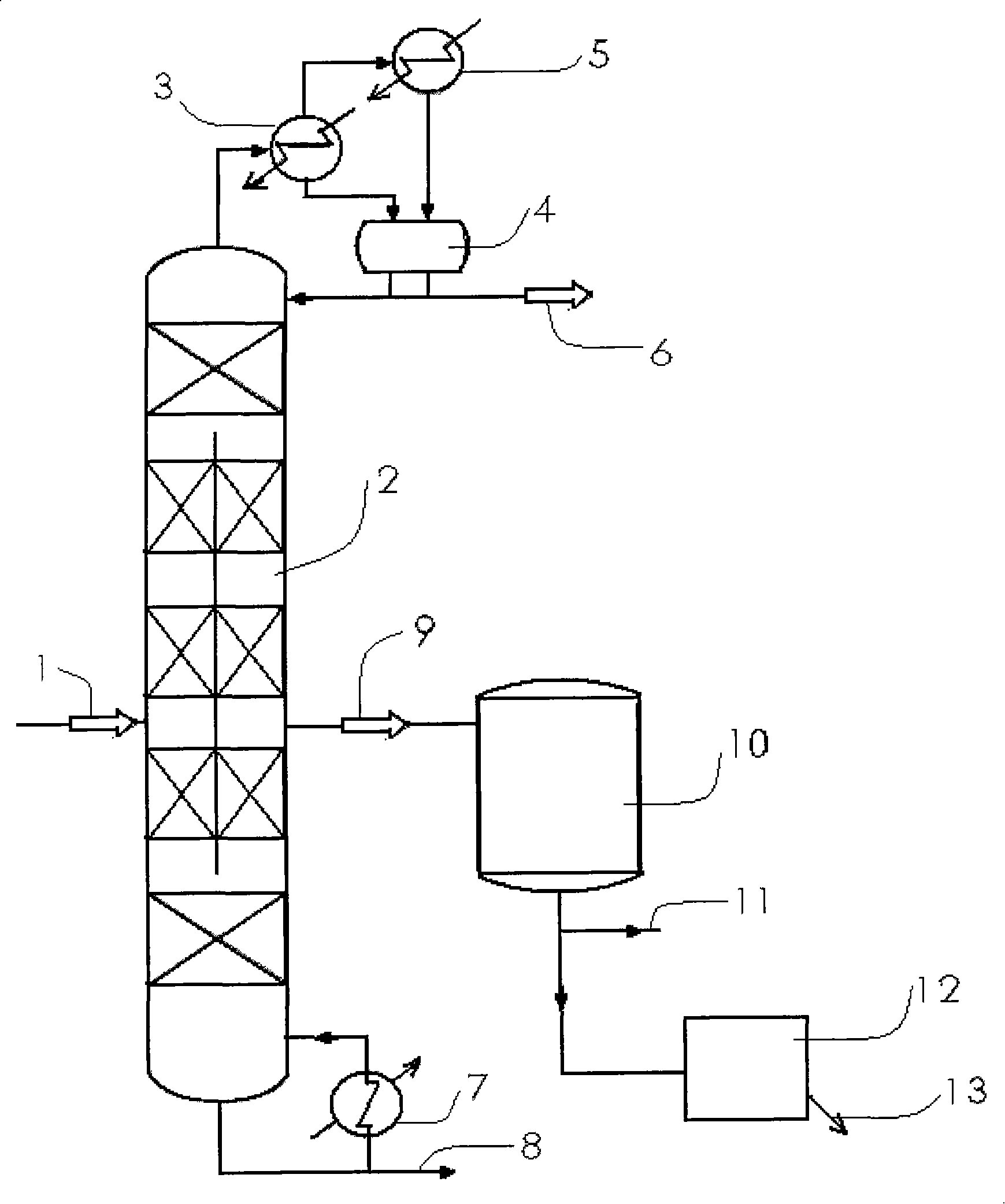

[0028] Please see attached figure 1 , will be purchased from China Petrochemical Group Yangzi Petrochemical Co., Ltd. in Liuhe District, Nanjing City, Jiangsu Province, China, with a naphthalene content of 3% carbon deca-heavy aromatics feedstock, at room temperature from the pipeline 1 lead through the diameter of 1.6m, tower The first tower top heat exchanger 3 of the first rectifying tower 2 with a height of 35m and 138 trays comes from the top of the first rectifying tower 2 and enters the first tower top heat exchanger 3 The light fraction distillate is heat exchanged, and after heat exchange, the C10 heavy aromatics raw material with a temperature of 68°C is introduced into the first rectification tower 2 from the middle and lower part of the tower body of the first rectification tower 2. rectification. The rectification conditions are controlled as follows: the temperature at the top of the first tower is 130°C, and the absolute pressure at the top of the tower is 19KP...

Embodiment 2

[0030] Only change the content of naphthalene in the carbon ten heavy aromatic hydrocarbon feedstock into 7%, and the 1000% distilled from the top of the first rectifying tower 2 # The temperature of the solvent is changed to 71° C., the temperature of the C10-heavy aromatics raw material after heat exchange is changed to 52° C., and the control conditions of the first rectifying tower 2: the tower top temperature is changed to 112° C., and the reflux ratio is changed to 1: 10. The absolute pressure at the top of the tower is changed to 15KPa, the heating temperature of the heat transfer oil at the bottom of the tower is changed to 280°C; the control conditions of the second rectification tower 10: the temperature at the top of the tower is changed to 130°C, the control reflux ratio is changed to 1:9, and the heat transfer oil at the top of the tower is changed to 1:9. Change the pressure to 15Kpa, change the temperature of the naphthalene-enriched liquid drawn from the second ...

Embodiment 3

[0032] Only change the content of naphthalene in the carbon ten heavy aromatics raw material into 5.9%, and the 1000% of the overhead distillate of the first rectifying tower 2 # The temperature of the solvent is changed to 76°C, the temperature of the carbon ten heavy aromatics raw material after heat exchange is changed to 61°C, and the first rectifying tower 2 control conditions: the tower top temperature is changed to 121°C, and the reflux ratio is changed to 1: 12. The absolute pressure at the top of the tower is changed to 17KPa, and the heating temperature of the heat transfer oil at the bottom of the tower is changed to 272°C; the control conditions of the second rectification tower 10: the temperature at the top of the tower is changed to 126°C, the control reflux ratio is changed to 1:10, and the heat transfer oil at the top of the tower is changed to 1:10. Change the pressure to 13KPa, change the temperature of the naphthalene-enriched liquid drawn from the side line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com