Method for preparing mixed methylnaphthalene by using C+10 heavy aromatic hydrocarbon as raw material

A technology for mixing methyl naphthalene and heavy aromatic hydrocarbons, applied in the preparation of β-methyl naphthalene, α field, can solve the problems of complex process, environmental pollution, equipment corrosion, etc., and achieves a process with few process steps, easy source of raw materials and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

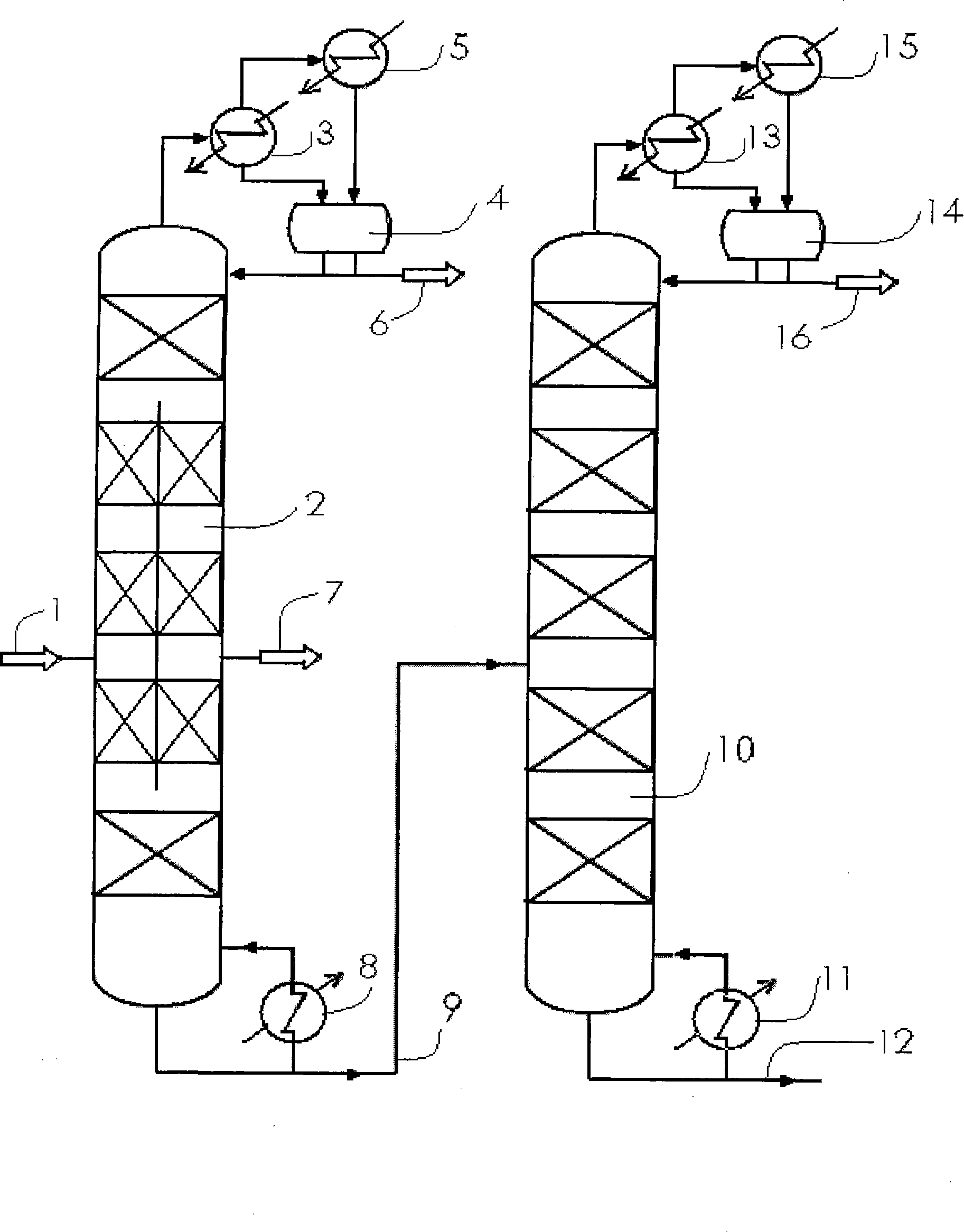

[0026] Please refer to the accompanying drawing. The methylnaphthalene content of 35.3% carbon deca aromatics raw material purchased from Nanjing Jiuyuan Petrochemical Co., Ltd., 26A5, Shangmao Century Plaza, No. 49, Zhongshan South Road, Nanjing City, Jiangsu Province, China, was placed at room temperature The pipeline 1 is introduced into the first rectification tower 2 from the middle and lower feed port of the first rectification tower 2 with a diameter of 1.2m, a tower height of 35m, and 112 trays for rectification. The reflux ratio is controlled as 1:10, the absolute pressure at the top of the tower is controlled at 10KPa, the temperature at the top of the tower is controlled at 112°C, the light fraction at the top of the first rectification tower 2 is cooled by the first tower top heat exchanger 3, and the liquid enters the first rectification tower 2 In the first overhead reflux tank 4 of the first rectification column, the uncondensed part enters the first overhead con...

Embodiment 2

[0028] Only change the content of methylnaphthalene in the C10 heavy aromatics raw material to 36.1%, the first rectifying tower 2 control: the reflux ratio is changed to 1:8, the absolute pressure at the top of the tower is changed to 15Kpa, the temperature at the top of the tower is changed to 120°C, The heating temperature of the heat transfer oil at the bottom of the tower is 295°C; the control of the second rectification tower 10: the reflux ratio is changed to 1:6, the absolute pressure at the top of the tower is changed to 20Kpa, the temperature at the top of the tower is changed to 156°C, and the heating temperature of the heat transfer oil at the bottom of the tower is changed to 292°C. All the other are with embodiment 1.

Embodiment 3

[0030] Only change the content of methylnaphthalene in the C10 heavy aromatics raw material to 37.5%, and the first rectifying tower 2 controls: the reflux ratio is changed to 1: 10, the absolute pressure at the top of the tower is changed to 13Kpa, the temperature at the top of the tower is changed to 119°C, The heating temperature of the heat transfer oil at the bottom of the tower is 280°C; the control of the second rectification tower 10: the reflux ratio is changed to 1:9, the absolute pressure at the top of the tower is changed to 22Kpa, the temperature at the top of the tower is changed to 160°C, and the heating temperature of the heat transfer oil at the bottom of the tower is changed to 281°C. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com