Ship craft integrated hydraulic propulsion method and device

A technology for propulsion devices and ships, applied in the direction of non-mechanical gear transmission devices, etc., can solve problems such as restricting the development of ships, achieve excellent working conditions with characteristics, high maneuverability, and improve system economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

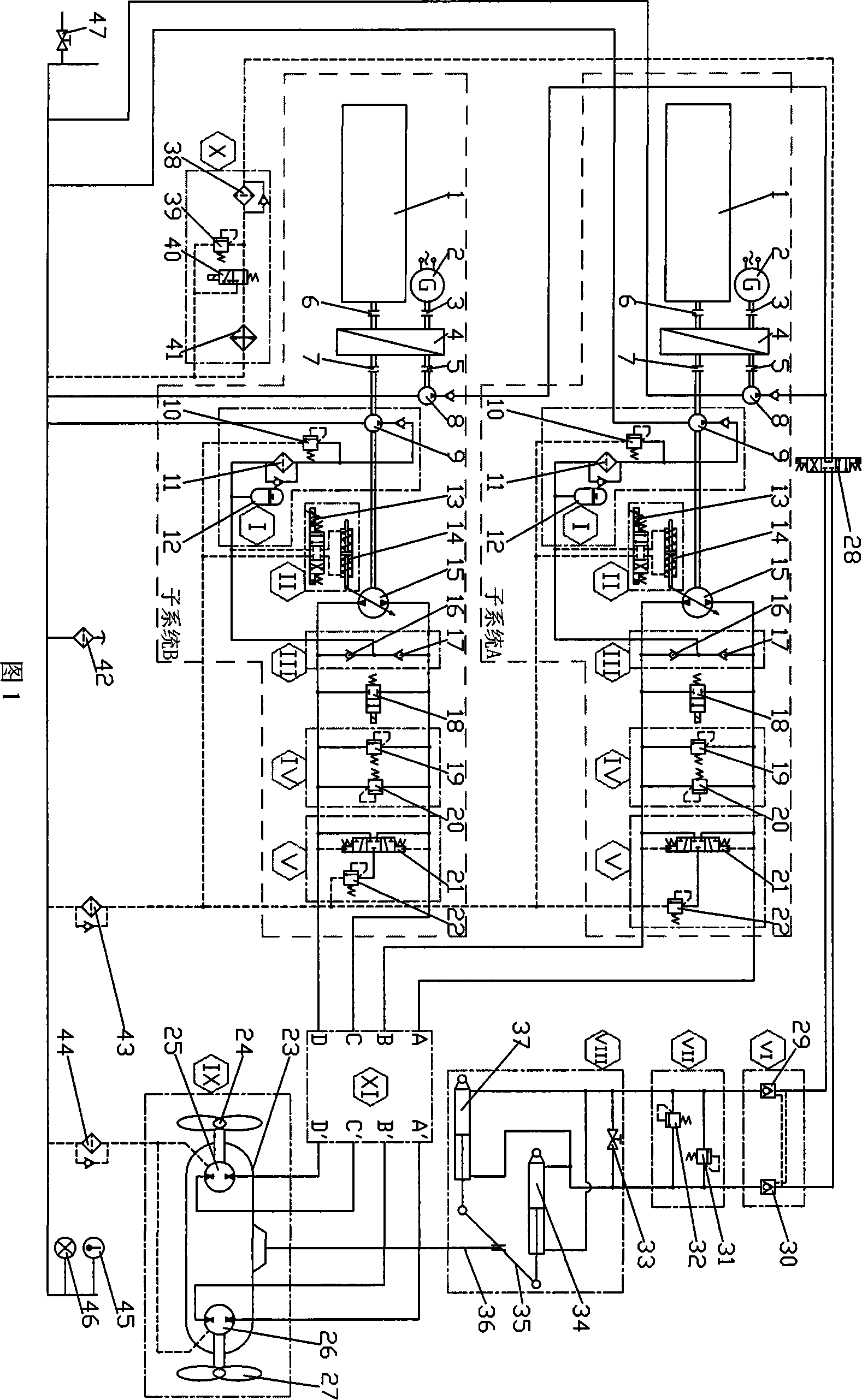

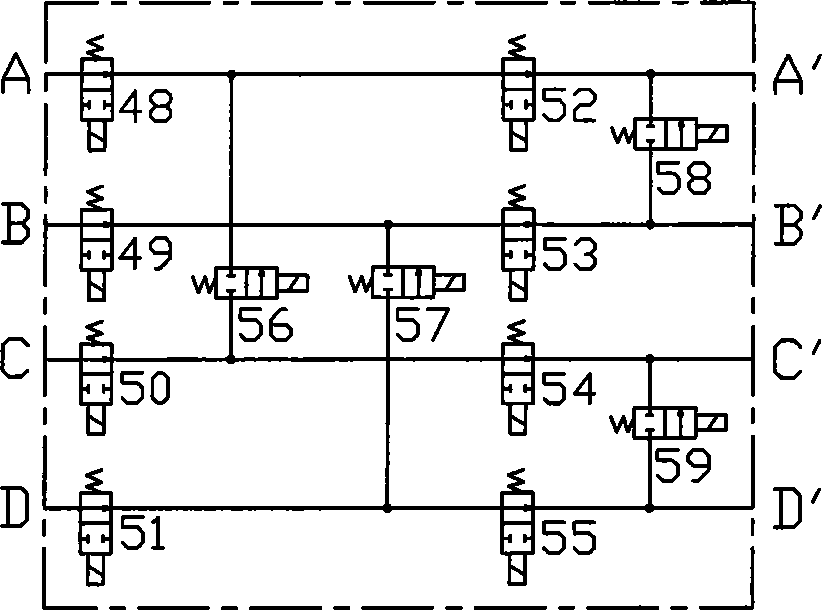

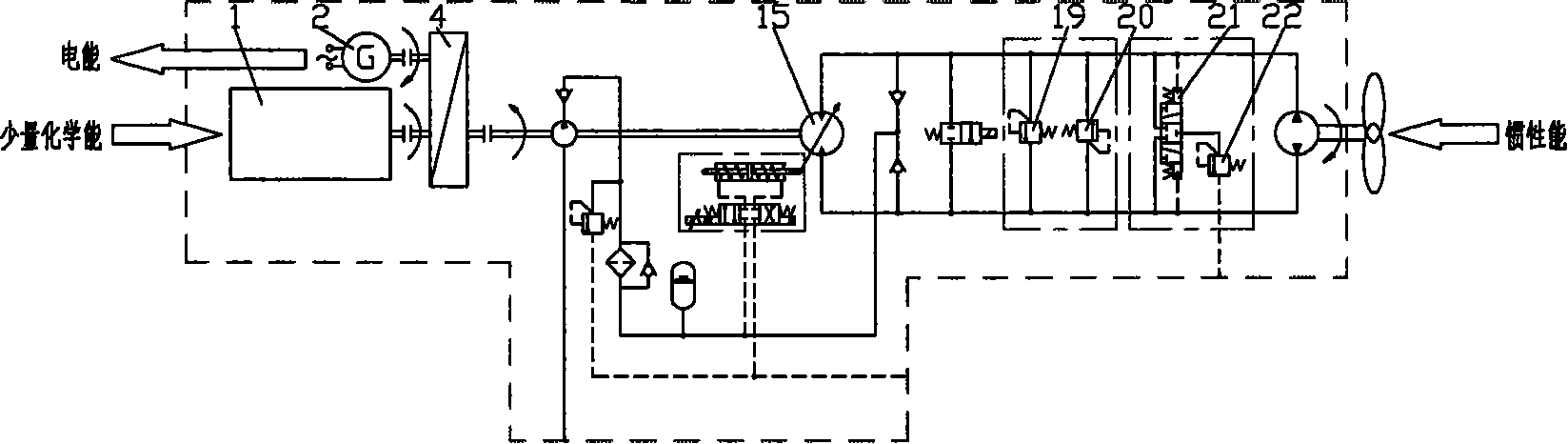

[0033] According to the power of the ship and the actual needs, select or design the appropriate parts 1~59, and follow the attached figure 2 , 3 Assembled as shown, reasonably arranged in a suitable position in the ship's engine room (not shown in the figure). When the system is running, host 1, first clutch 3, second clutch 5, third clutch 6, fourth clutch 7, servo valve 13, start valve 18, three-position four-way solenoid valve 28, two-position three-way solenoid valve 40 And all the electromagnetic reversing valves (48-59) in the eleventh combined element are controlled by a computer (not shown in the figure) in a unified manner.

[0034] When receiving the starting command, open the third clutch 6, the main engine 1 is in a light-load state; the starting valve 18 is energized, and the suction and discharge ports of the two-way variable pump 15 are connected. When the main engine 1 reaches the set speed, close the third clutch 6, The hydraulic system is driven to work. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com