Production method of miniature radiation detection chip

A technology of radiation detection and manufacturing method, which is applied in the field of electrical replacement of absolute radiometers and the production of micro-radiation detection chips, which can solve the problems of large influence of lead wire resistance, low sensitivity of thermopile ring, large detectable power, etc., and achieve sensitivity and response Increased temperature, good long-term stability, and rapid heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

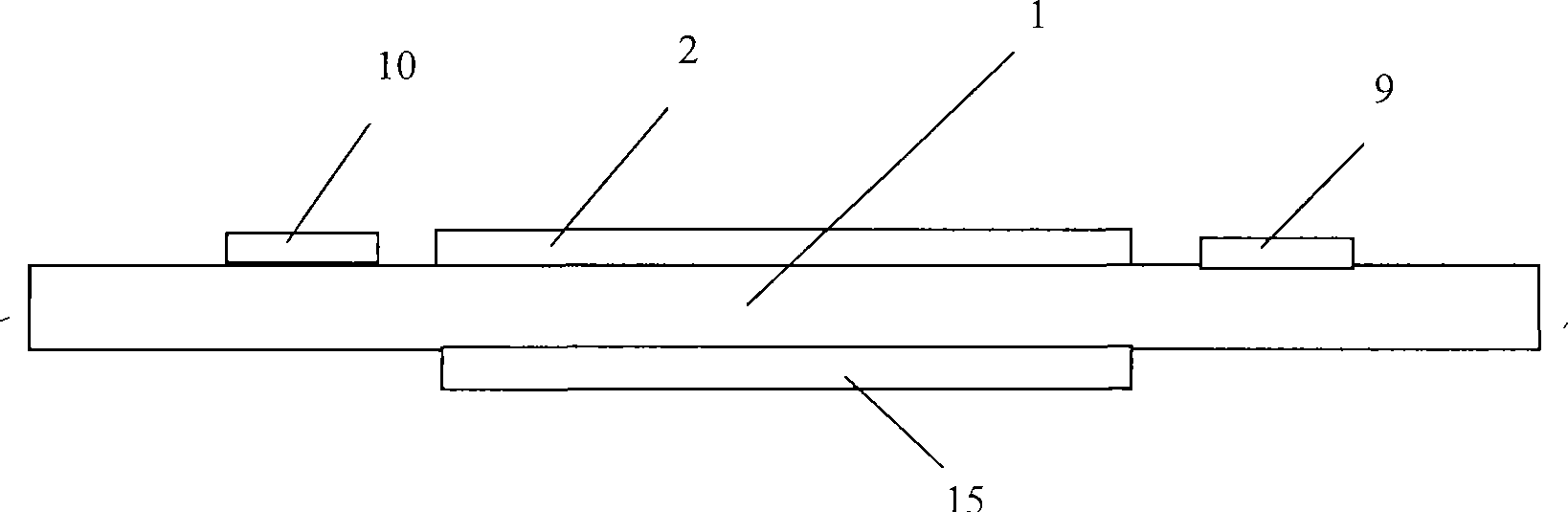

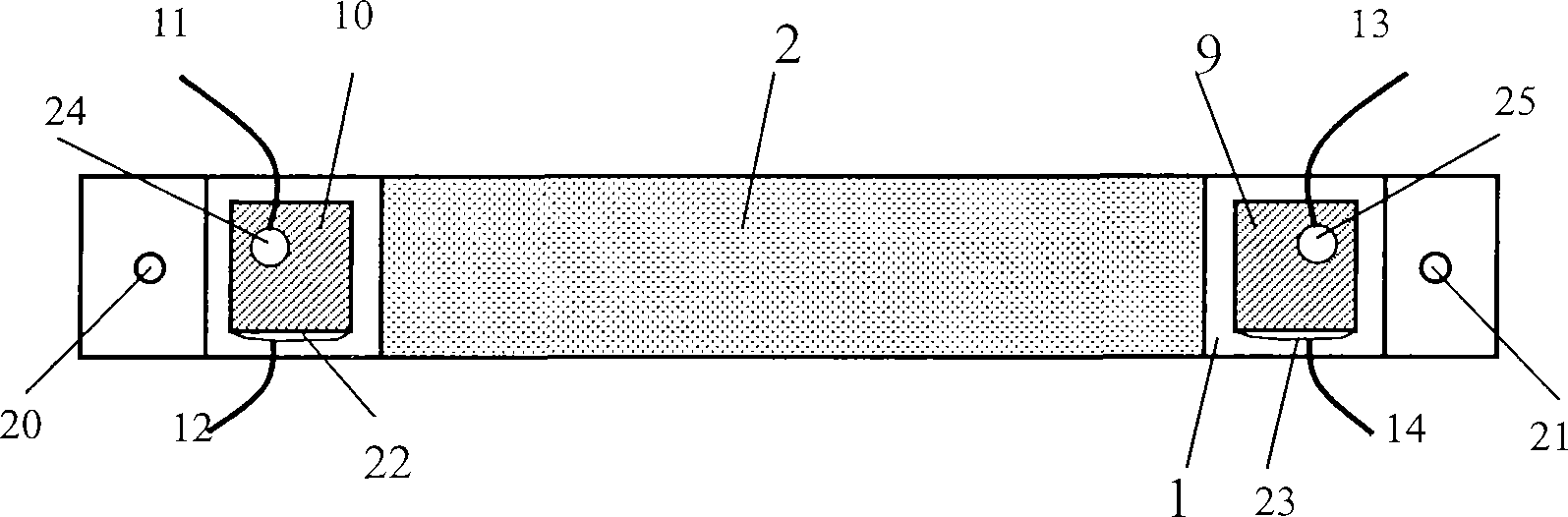

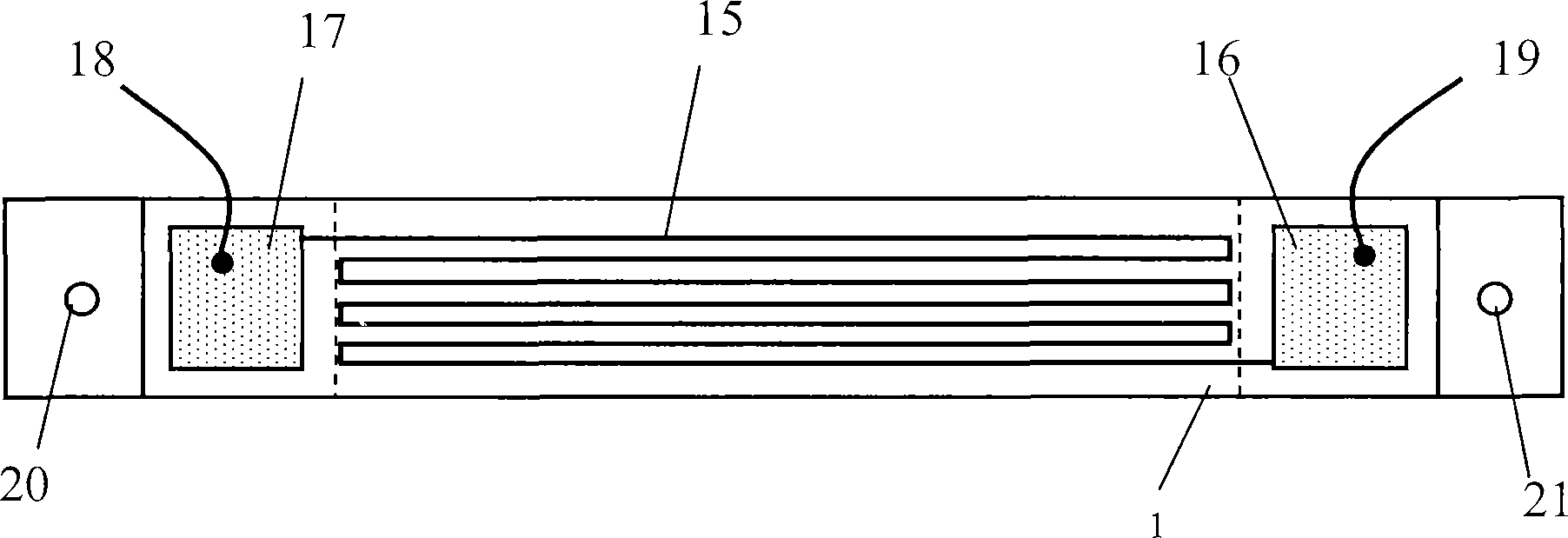

[0026] like figure 2 , 3As shown, the miniature radiation detection chip made by the present invention includes a substrate 1, a radiation absorbing material 2, thermistors 9, 10, thermistor upper electrode leads 11, 13, thermistor lower electrode leads 12, 14, heating wire 15. Heating wire pressure points 16, 17, heating wire leads 18, 19, holes 20, 21, conductive adhesive materials 22, 23 for the thermistor lower electrode, and conductive adhesive materials 24, 25 for the thermistor upper electrode. The substrate 1 is a rectangular sheet with a certain thickness, and its upper and lower surfaces are respectively called a surface and b surface. Surface a of the substrate 1 is distributed with radiation absorbing material 2, thermistors 9, 10, thermistor upper electrode leads 11, 13, thermistor lower electrode leads 12, 14, holes 20, 21, thermistor lower electrodes Conductive adhesive materials 22, 23 and conductive adhesive materials 24, 25 for the upper electrode of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Rough | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com