Enclosed cavity type heat exchanger

A closed cavity and heat exchanger technology, applied in the field of liquid-liquid heat exchange and in-tube reaction, can solve the problems of increased equipment cost, low heat transfer coefficient, increased heat exchanger cost, etc., to achieve cost saving, efficient heat transfer, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described now in conjunction with accompanying drawing

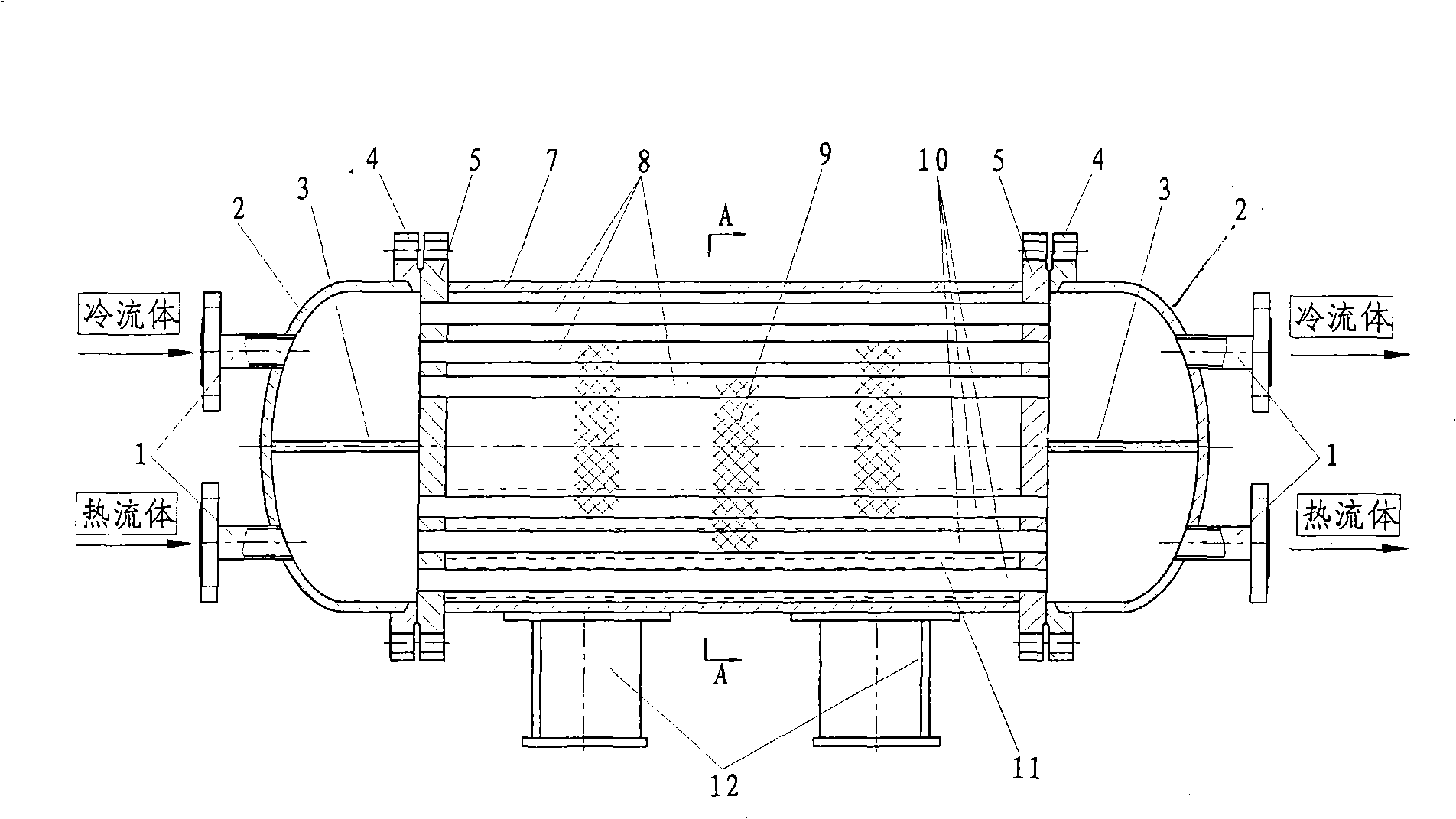

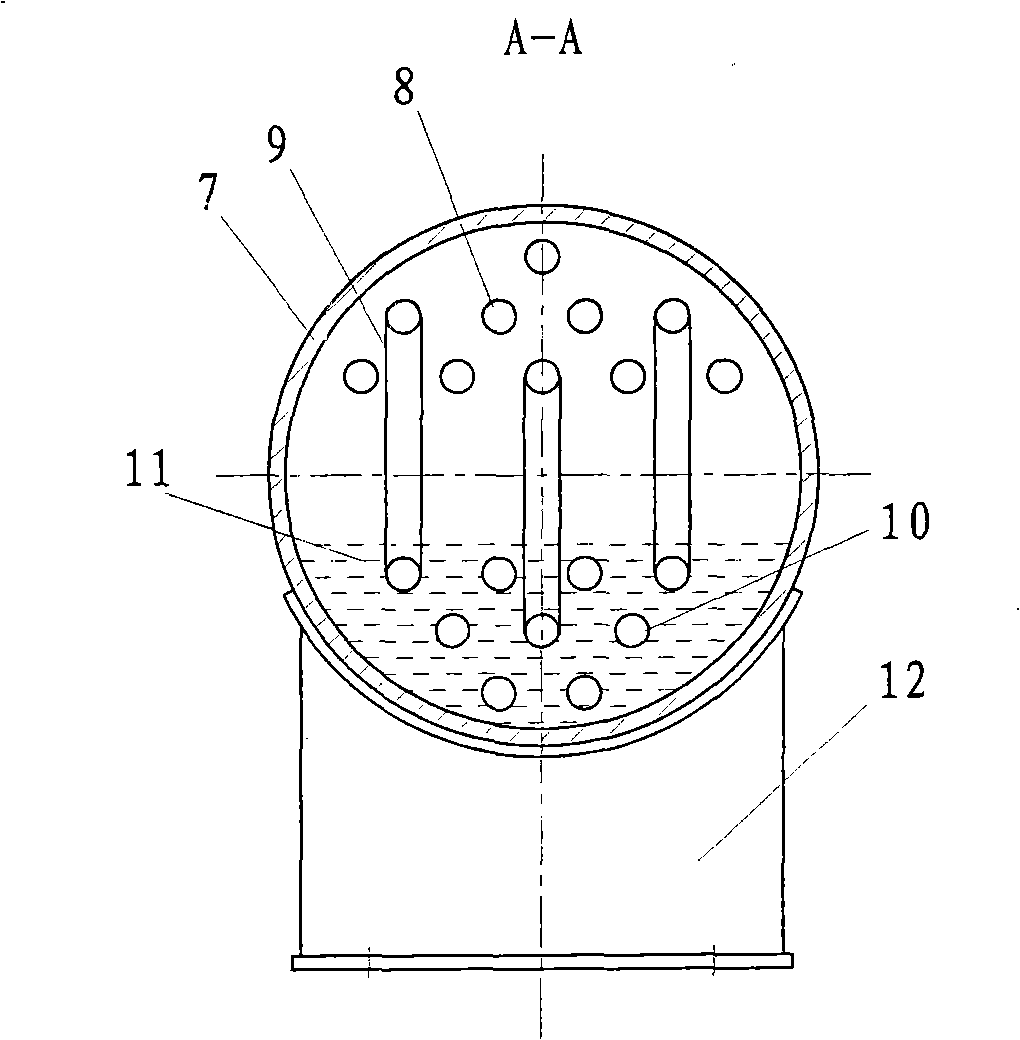

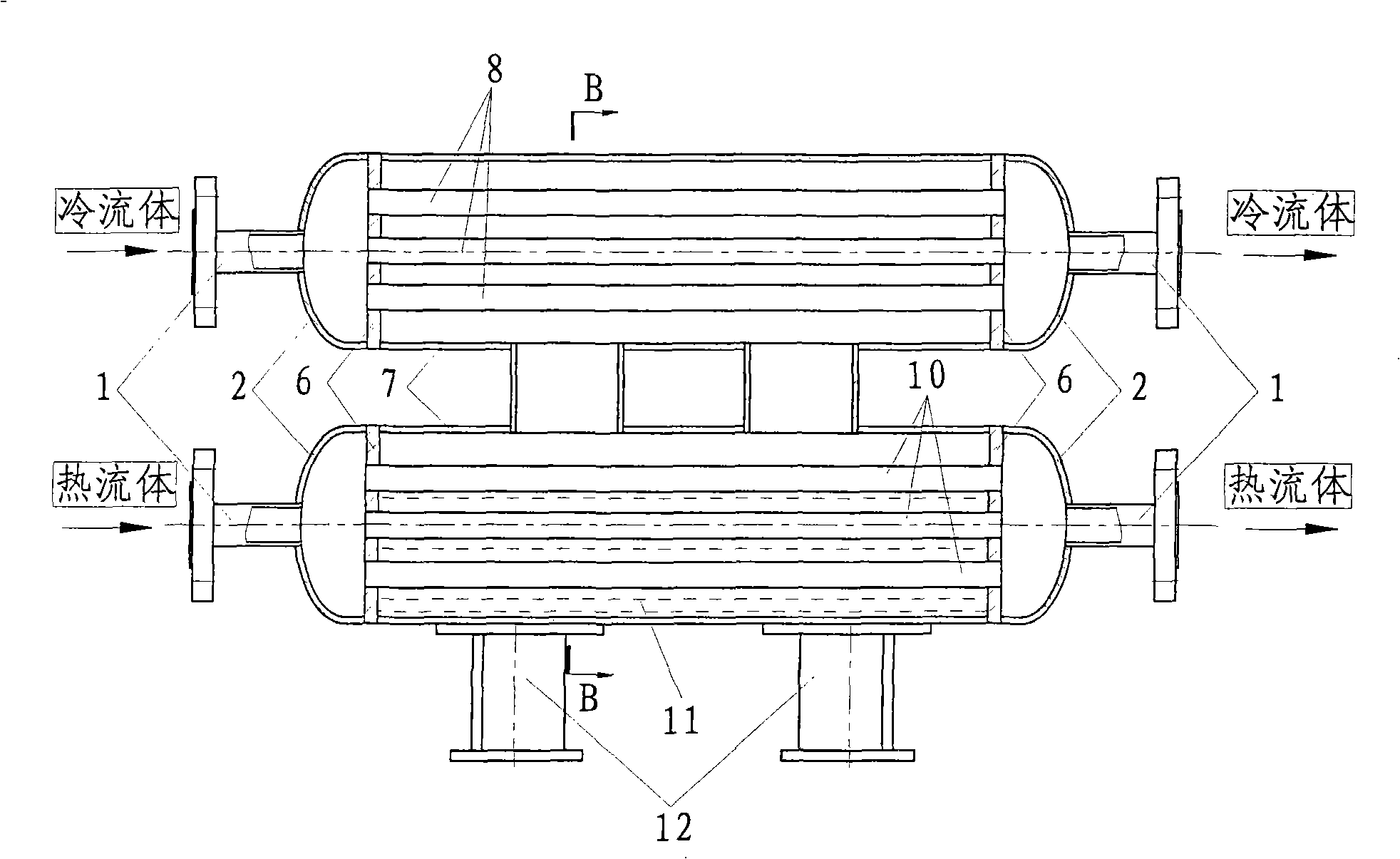

[0017] The closed cavity heat exchanger includes a vacuum sealed cavity, a heat exchange tube bundle, a working medium and a casing used as a fluid channel. Its structure is: the two ends of the orifice plate 5 and the horizontal cylindrical shell 7 are sealed, and the cold fluid heat exchange The tube bundle 8 and the hot fluid heat exchange tube bundle 10 pass through the orifice plate 5 and seal to form a cavity; the cold fluid heat exchange tube bundle 8 is located in the upper space of the cavity, and the hot fluid heat exchange tube bundle 10 is located in the lower space of the cavity; the vacuum state The airtight chamber of the cylinder is filled with working medium 11; the inner cavity of the cold and hot fluid heat exchange tube bundles communicates with the casing 2 with the connection pipe 1 at both ends, forming independent fluid passages respectively; the outer b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com