Magnetic rheologic pilot-operated reversing valve for hydraulic support

A technology of electro-hydraulic control reversing valve and magneto-rheological valve, which is applied in the direction of mine roof support, pillar/support, mining equipment, etc., and can solve the problem that the solenoid valve does not meet the explosion-proof performance requirements, the servo valve cannot work normally, and cannot be guaranteed to use and other problems, to achieve the effect of simple manufacturing process, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

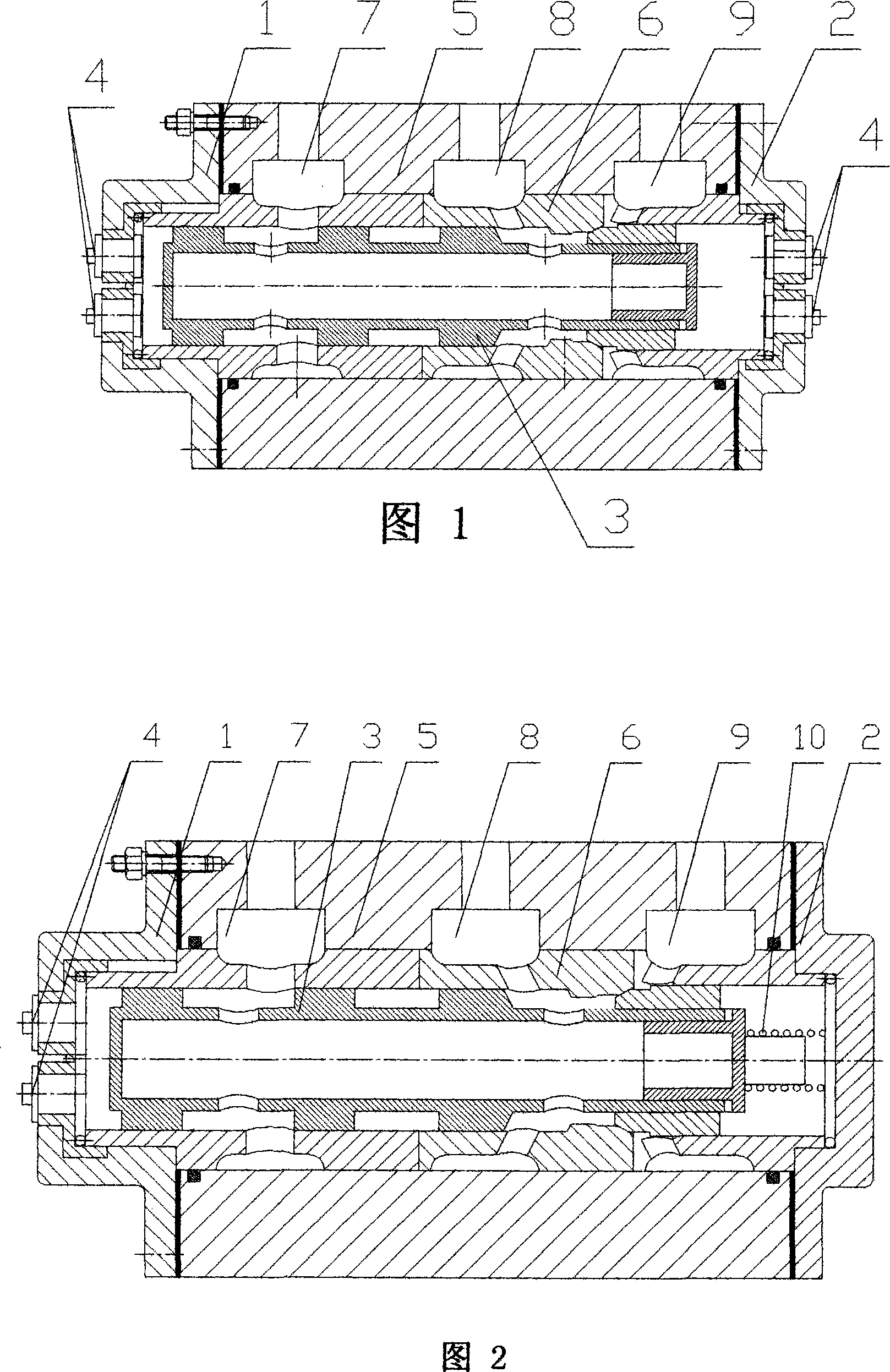

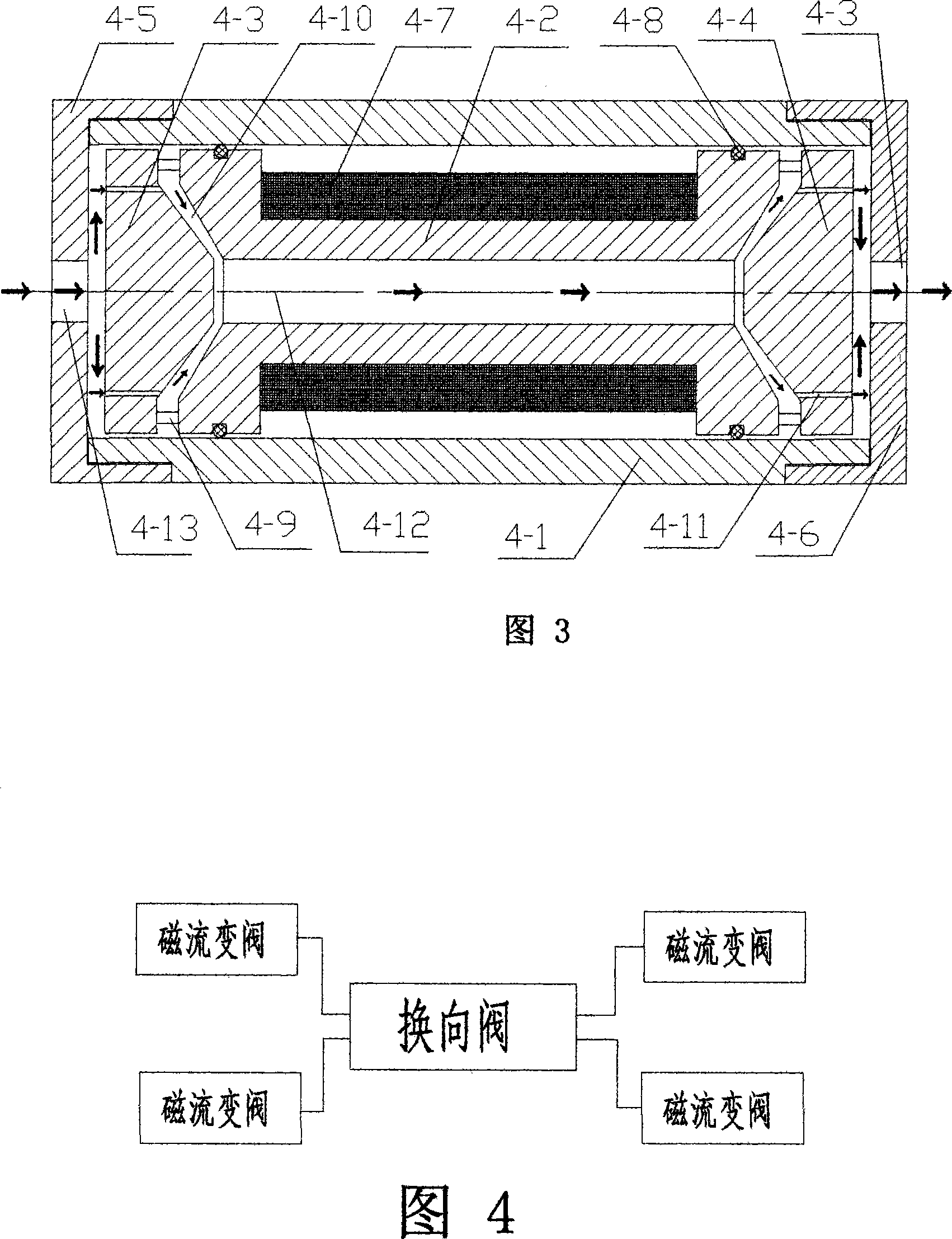

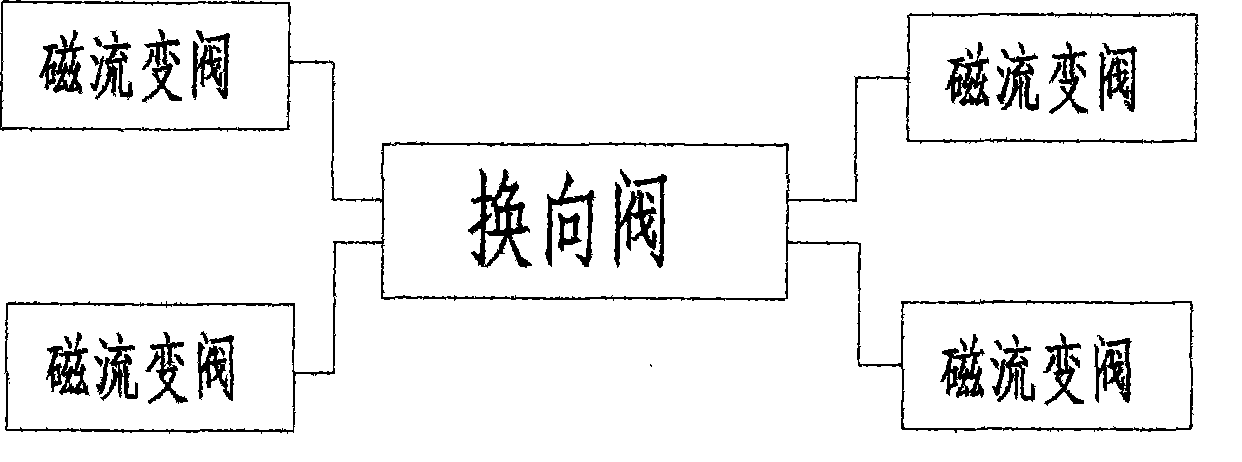

[0021] Referring to the accompanying drawings, the magneto-rheological electro-hydraulic control reversing valve for hydraulic support includes: reversing valve body 5, reversing valve left end cover 1, reversing valve right end cover 2, reversing inner valve core 3, reversing outer The spool 6 and the reversing valve working liquid port 7, the liquid inlet port 8 and the reversing valve return port 9, the reversing outer spool 6 is fixedly installed in the reversing valve body 5, and the reversing inner spool 3 is sealed and contacted. Set in the reversing outer valve core 6, the reversing valve working liquid port 7, the liquid inlet port 8 and the reversing valve return port 9 are moved by the reversing inner valve core 3 through the inner cavity of the reversing inner valve core 3 To realize the reversing, the left end cover 1 of the reversing valve and the right end cover 2 of the reversing valve are fixed to both ends of the reversing valve body 5, and the left end cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com