Packing method for adhesive tape at the bottom of lithium ion battery pole group

A technology for lithium-ion batteries and electrode groups, which is applied in electrode manufacturing, secondary batteries, circuits, etc., can solve problems such as incomplete sealing of tapes, contusions on battery cases, and eversion of diaphragms, so as to avoid contusions, complete sealing, and eliminate safety hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

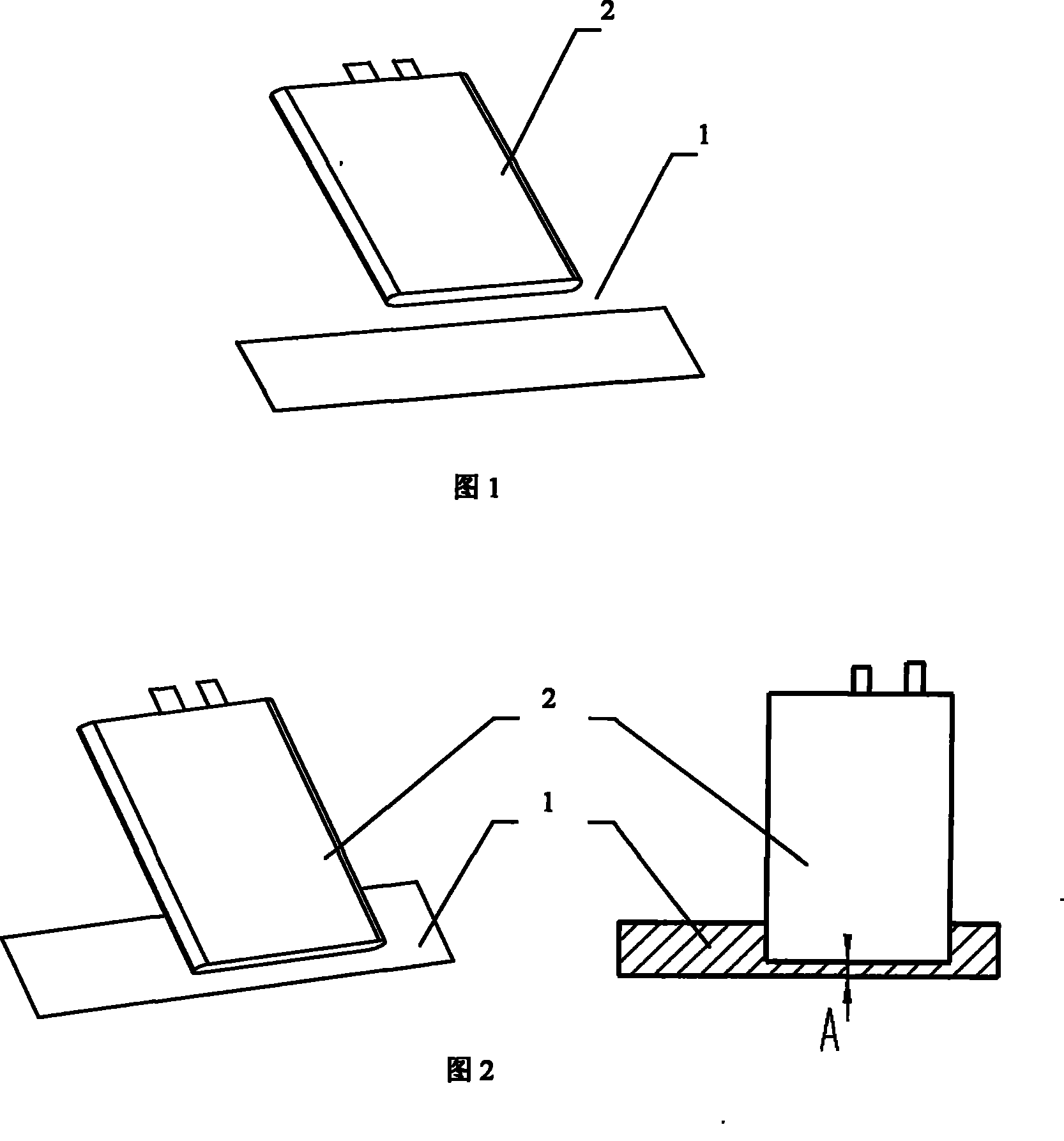

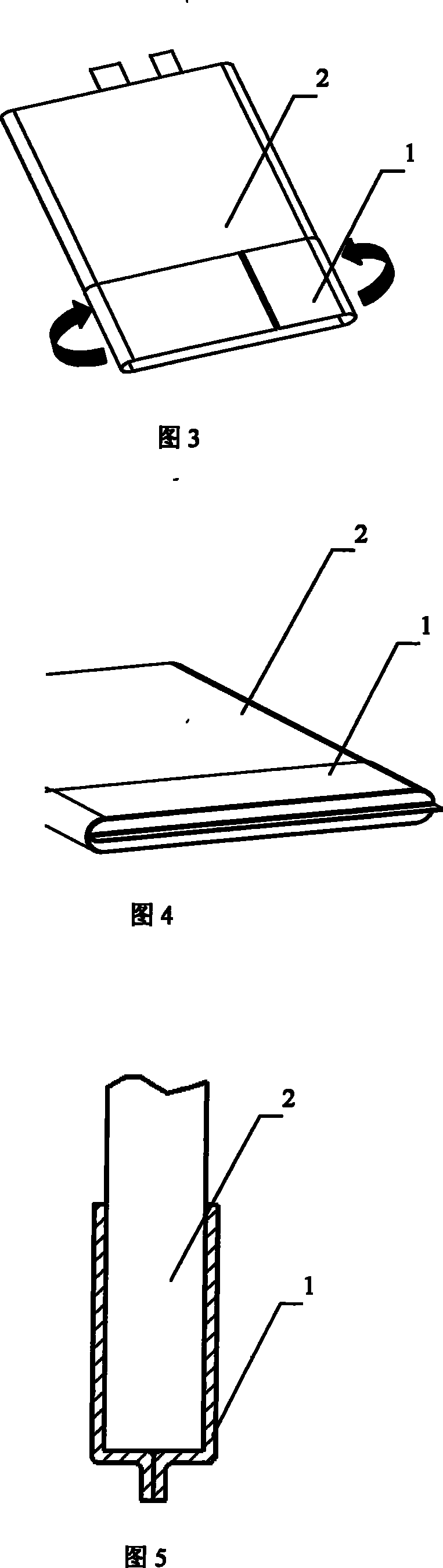

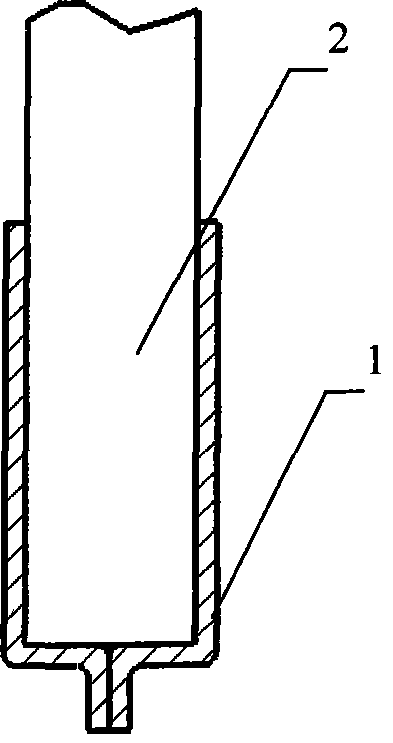

[0024] Below in conjunction with above-mentioned accompanying drawing, the present invention will be further described, in each following figure: Adhesive tape 1, pole group 2.

[0025] Step 1: As shown in Figure 1 above, cut the tape, and the length of the cut should be equal to the circumference of the pole group in the width direction;

[0026] Step 2: As shown in Figure 2 above, paste the tape on the wide surface of the bottom of the pole group. The dimension A where the tape exposes the bottom of the pole group should be equal to the thickness of the pole group;

[0027] Step 3: As shown in Figure 3 above, wrap the tape around the bottom of the pole group and paste it. When pasting, the direction of force should be perpendicular to the wide surface of the pole group;

[0028] Step 4: As shown in picture 4 above, pinch the exposed tape on both sides of the bottom of the pole group together without leaving any gaps.

[0029] As shown in Figure 5, it is a section view of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com