6 freedom degree precision positioning station capable of compensating z-direction position

A technology of positioning stage and degree of freedom, which is applied in the direction of workbench, photolithographic process exposure device, manufacturing tool, etc., can solve the problems of small stroke and complex overall structure, and achieve the effect of reducing Abbe error, reducing cost and being easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The six-degree-of-freedom precision positioning table capable of compensating the Z-direction position of the present invention will be further described in detail below.

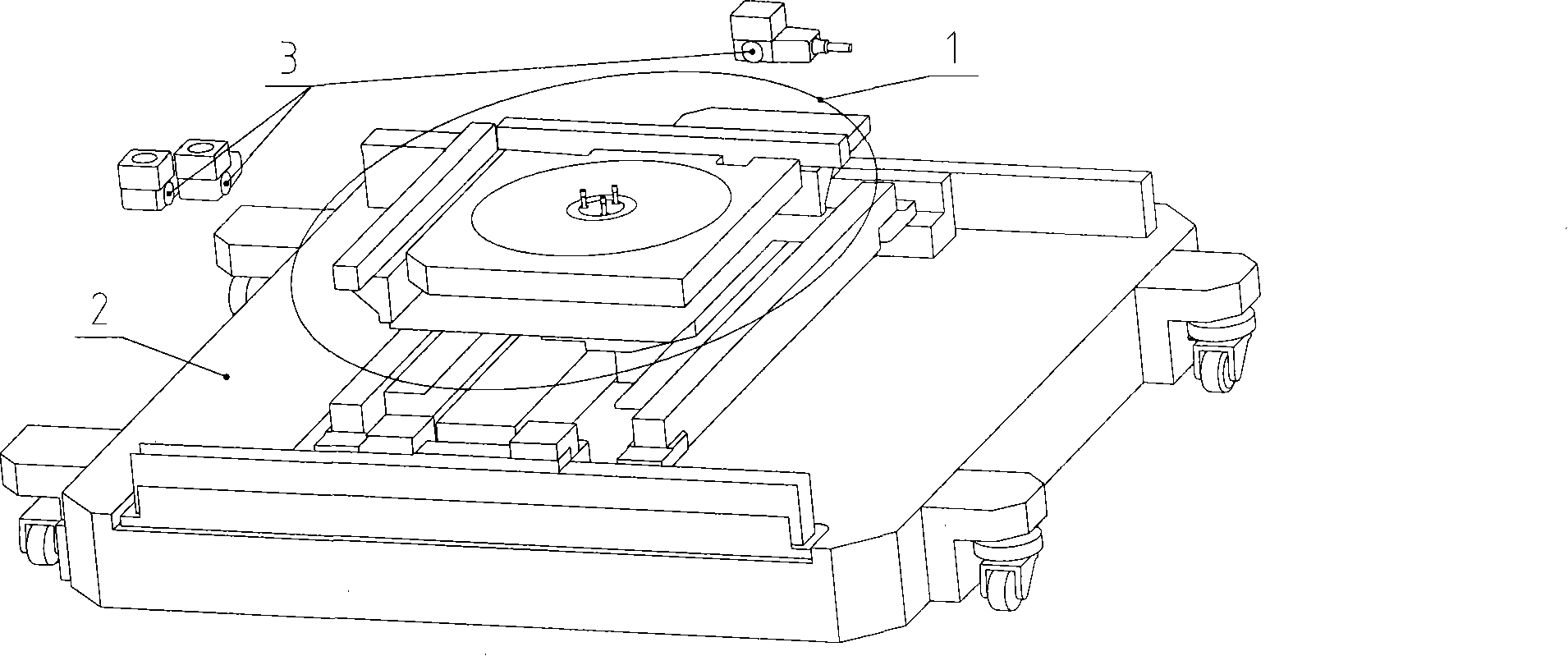

[0023] Such as figure 1 As shown, the six-degree-of-freedom precision positioning stage capable of compensating Z-direction position of the present invention is mainly divided into a horizontal positioning stage 1 (hereinafter referred to as the XY stage) and an exposure stage 2, wherein the exposure stage 2 is on the upper layer of the XY stage 1.

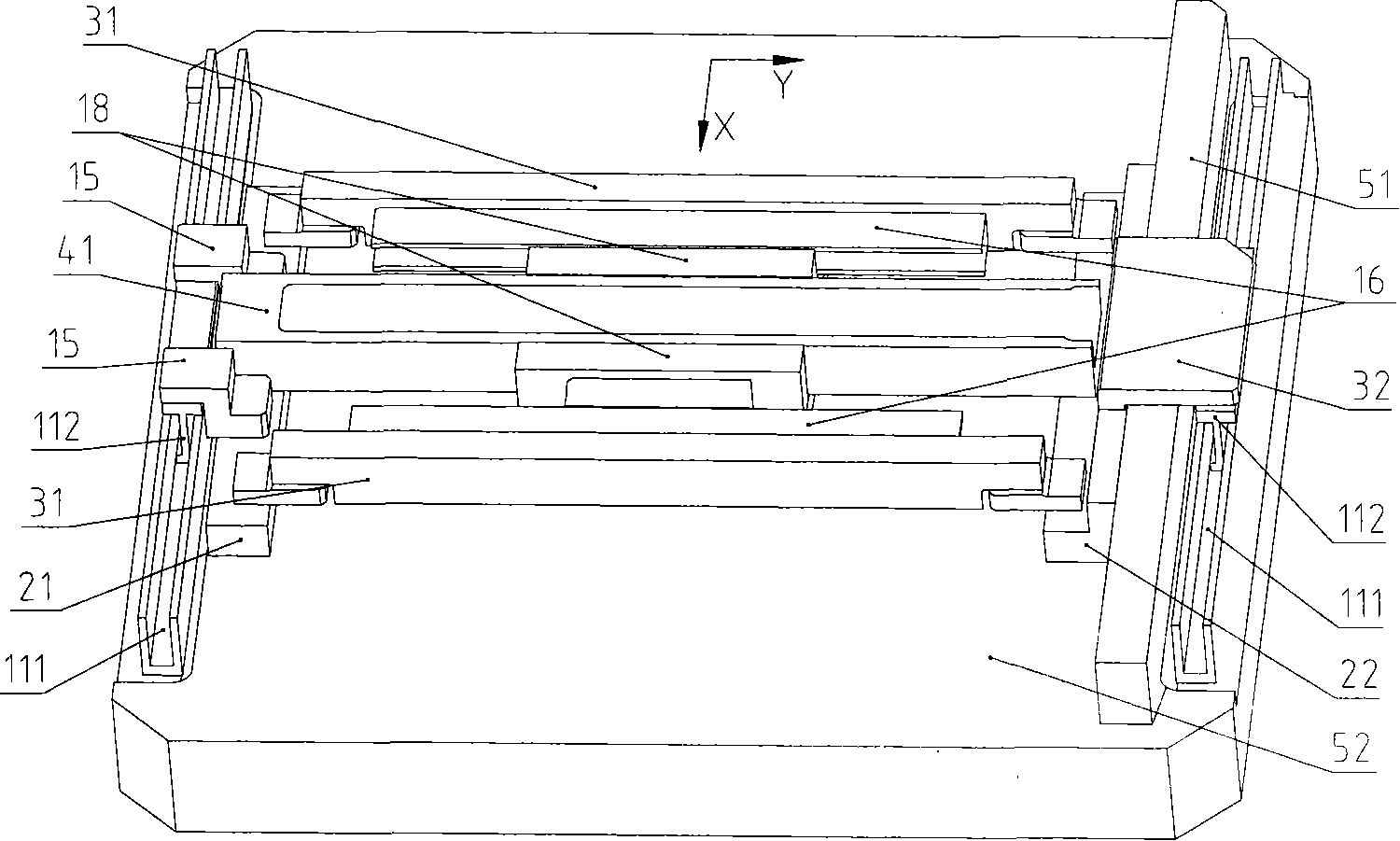

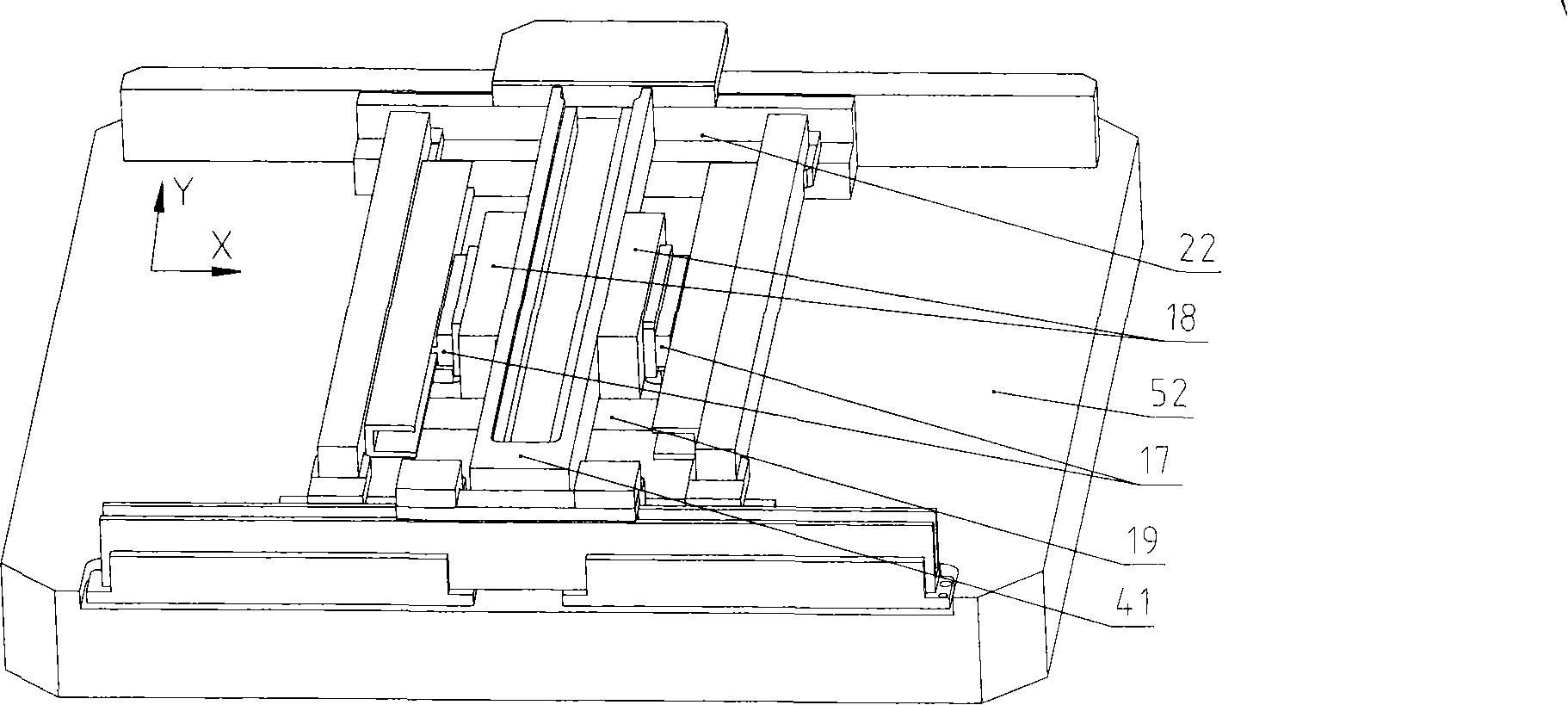

[0024] The XY stage is a horizontal precision positioning stage, the purpose is to achieve precise positioning in the horizontal direction (X, Y direction) through "a set of horizontal drive + precise and effective transmission mechanism + closed-loop control". The specific structure is as figure 2 and image 3 shown.

[0025] figure 2 Among them, the stators 111 of the two X-direction linear motors are respectively fixed on both sides of the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com