Method for processing foamed aluminum and application

A processing method, foamed aluminum technology, applied in the application field of this material, can solve the problems of low strength, affecting vehicle speed and performance, limited wood resources, etc., and achieve the effect of good flame retardancy, low manufacturing cost, and uniform quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

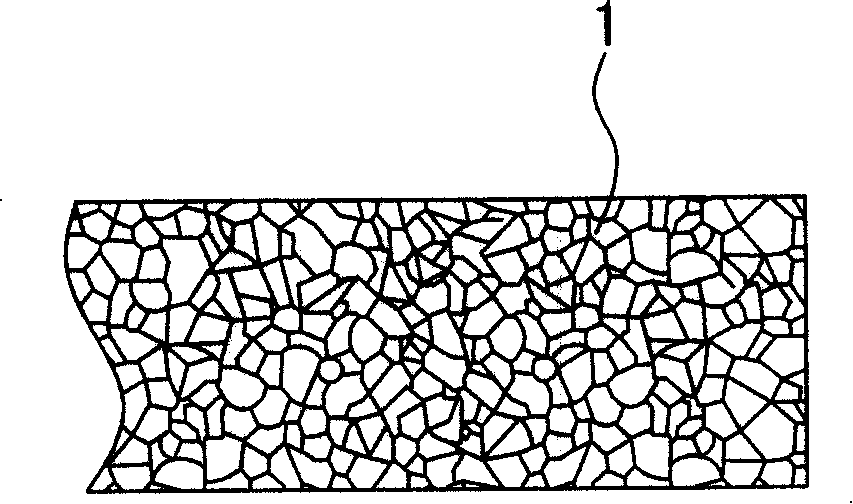

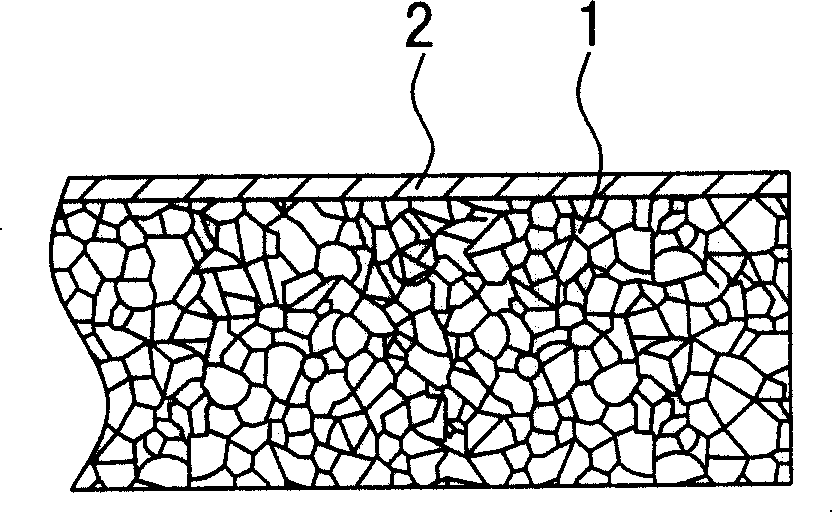

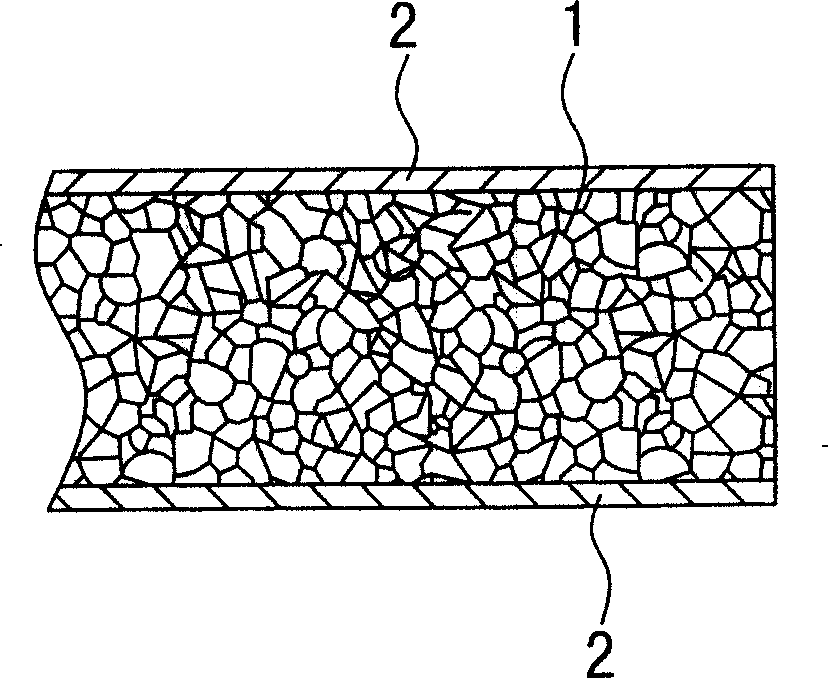

[0021] The invention discloses a processing method of foamed aluminum material, which has a mold container, which is characterized in that an air outlet is formed at the bottom of the mold container, and the specific processing steps are: ① Put 40% to 60% of granular salt in the mold container As a filler, take the best value of 50%; ②, roasting filler: put the mold container with filler into the roasting furnace, and heat it up to 500-650°C at a rate of 5°C per minute, the best is 630°C , keep warm for 30 minutes, remove the moisture in the granular salt, and then air-cool; ③, take out the roasted granular salt, put it on a sieve for sieving to obtain the required size and uniform granular salt; ④, put the granular salt again When loading the mold with salt, it should be loaded and compacted in layers. The thickness of each layer is about 50mm, spray a little water mist, and then compact; The temperature is preheated for 60 minutes, preferably 700°C, to achieve sufficient pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com