Convenient for cleaning hollow fiber membrane, preparation of the same and products produced thereby

A hollow and fiber technology, applied in the field of polyvinylidene fluoride hollow fiber smart membrane, can solve problems such as shortening the service life, achieve the effects of not easy to run off, improve hydrophilicity, good temperature and pH value sensitivity or responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

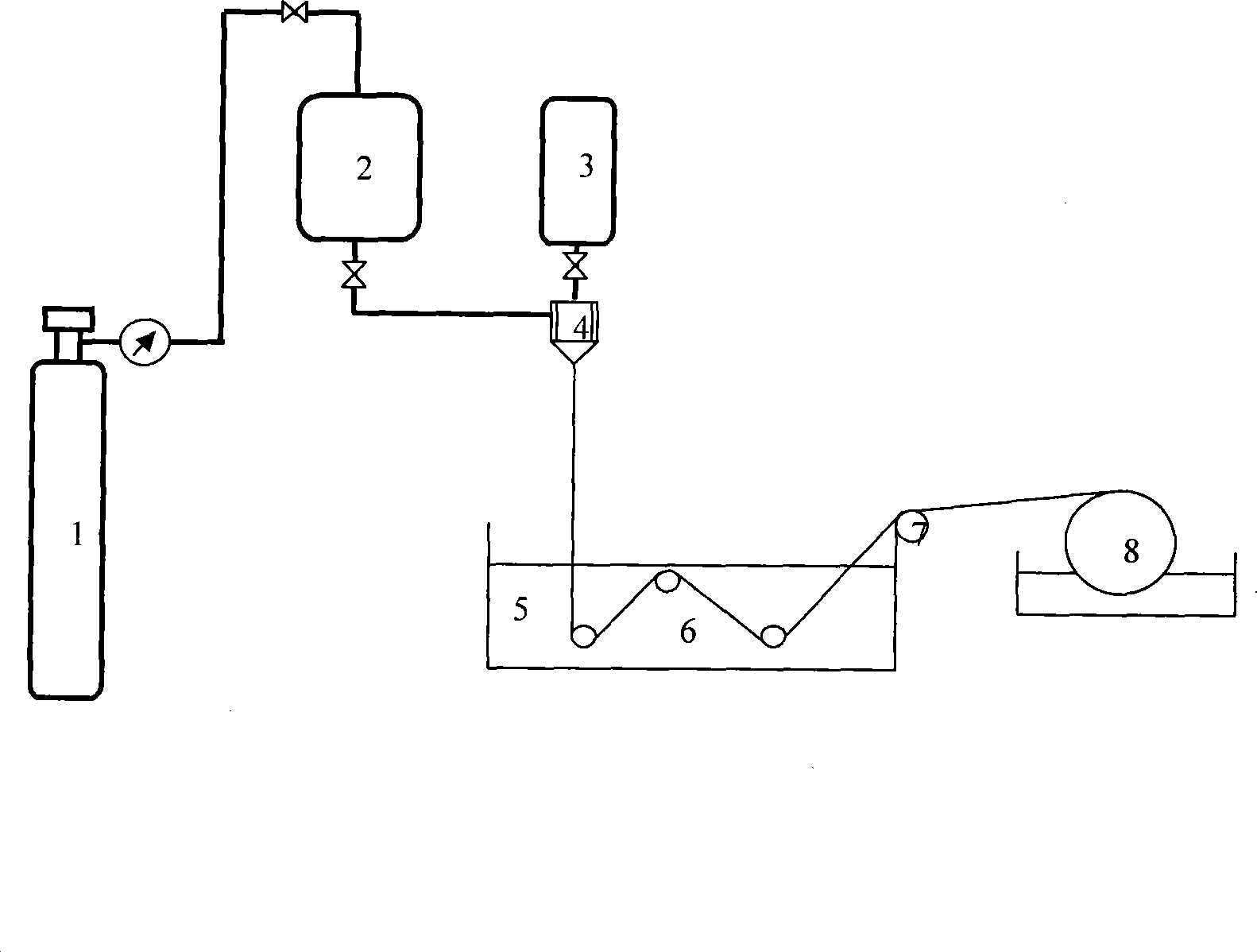

Method used

Image

Examples

Embodiment 1

[0070] At 70°C, prepare the feed solution in the following proportions: 17% by weight of polyvinylidene fluoride, 3% by weight of polyvinylidene fluoride-acrylic acid-isopropylacrylamide three-component copolymer prepared by the method of the present invention, 10% by weight % polyethylene glycol, 10% by weight polyvinylpyrrolidone, 1% by weight lithium chloride, 1% by weight Tween-80, 0.5% by weight water, 57.5% by weight dimethylacetamide. The dry-wet spinning method is used for spinning, the dry spinning length is 5 cm, the temperature of the spinning solution is 70 ° C, the core liquid adopts a dimethylacetamide aqueous solution with a weight concentration of 40%, and the coagulation bath adopts a weight concentration of 20%. The dimethylacetamide aqueous solution, the temperature of the coagulation bath is 30 ℃, and the hollow fiber membrane is prepared according to the method disclosed in this specification; its inner diameter is 0.7 mm, the outer diameter is 1.3 mm, and ...

Embodiment 2

[0072] The feed liquid contains 19% by weight of polyvinylidene fluoride and 1% by weight of polyvinylidene fluoride-acrylic acid-isopropylacrylamide three-component copolymer, and the remaining components and spinning process are the same as in Example 1. The inner diameter of the hollow fiber membrane is 0.7mm, the outer diameter is 1.3mm, and the pure water flux is 190L / m 2.h (0.04MPa, external pressure), the average pore size is 0.05 microns. When used to filter the effluent of the secondary sedimentation tank of the sewage treatment plant, the sewage flux is 55L / m 2 .h (20°C, 0.04MPa, external pressure, running for 30 minutes, air-water backwashing for 1 minute), after 60 days, the sewage flux will drop to 36L / m 2 .h, wash with pure water at 20°C for 30 minutes, and its sewage flux returns to 44L / m 2 .h, the recovery rate is 80%; wash with hydrochloric acid aqueous solution with a pH value of 2 at 40°C for 15 minutes, and its sewage flux returns to 52L / m 2 .h.bar, the ...

Embodiment 3

[0074] The feed solution contained 19.8% by weight polyvinylidene fluoride and 0.2% by weight polyvinylidene fluoride-acrylic acid-isopropylacrylamide three-component copolymer, and the remaining components and spinning process were the same as in Example 1. The inner diameter of the hollow fiber membrane is 0.7mm, the outer diameter is 1.3mm, and the pure water flux is 150L / m 2 .h (0.04MPa, external pressure), the average pore size is 0.05 microns. When used to filter the effluent of the secondary sedimentation tank of the sewage treatment plant, the sewage flux is 48L / m 2 .h (20°C, 0.04MPa, external pressure, running for 30 minutes, air-water backwashing for 1 minute), after 60, the sewage flux will drop to 31L / m 2 .h, wash with pure water at 20°C for 30 minutes, and its sewage flux returns to 36L / m 2 .h, the recovery rate is 75%; wash with hydrochloric acid aqueous solution with a pH value of 2 at 40°C for 15 minutes, and its sewage flux recovers to 42L / m 2 .h.bar, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com