Mycotoxin purification column and mycotoxin purification method

A mycotoxin and purification column technology, applied in chemical instruments and methods, separation methods, solid adsorbent liquid separation, etc., can solve the problems of unsatisfactory purification effect, limited application range, long processing time, etc., and achieve stable properties and applicable Wide range of effects at low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

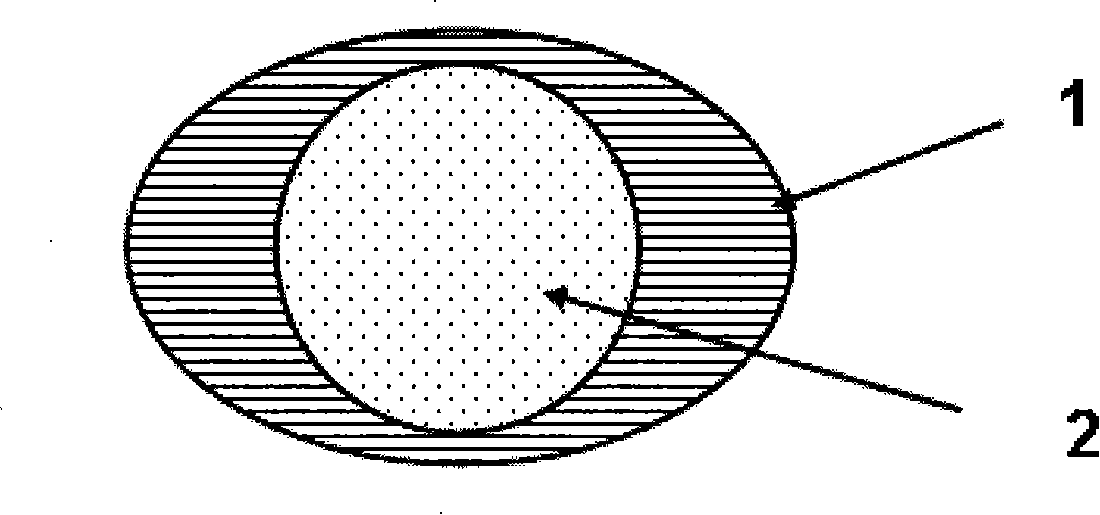

Image

Examples

Embodiment 1

[0025] Items to be inspected: peanut butter;

[0026] Mycotoxin type: aflatoxin;

[0027] Purification column packing configuration: packing 2.5g, including silica gel (Qingdao Hailang Silica Gel Desiccant Factory) 1.35g, neutral alumina (Zhengzhou Inno Chromatography Experimental Technology Co., Ltd.) 0.9g, filter aid (diatomaceous earth ZX-616, Beijing Langjie Pudao Filtration Technology Co., Ltd.) 0.25g;

[0028] The purification method includes the following steps:

[0029] The first step is to prepare the sample solution, extract the target analyte in peanut butter twice with 20ml of acetonitrile / water (v / v: 10 / 90) mixture, and combine the extracts;

[0030] The second step is to load the sample, take 2ml of the extract and add it to the purification column, and collect the effluent;

[0031] The third step is to elute with methanol as the eluent, flow through the purification column with 4ml of acetonitrile, drain under negative pressure, and collect the effluent;

...

Embodiment 2

[0034] Object to be inspected: paddy;

[0035] Types of mycotoxins: aflatoxins, trichothecenes;

[0036] Purification column packing configuration: packing 2.5g, including 0.9g silica gel, 1.35g neutral alumina, and 0.25g filter aid (Celite545, Merck Chemical Technology (Shanghai) Co., Ltd.);

[0037] The purification method includes the following steps:

[0038] The first step is to prepare the sample solution, extract the analytes in the rice twice with 20ml of acetonitrile / water (v / v: 16 / 84) mixture, and combine the extracts;

[0039] The second step is to load the sample, take 2ml of the extract and add it to the purification column, and collect the effluent;

[0040] The third step is to elute with acetonitrile as the eluent, flow through the purification column with 4ml of acetonitrile, drain under negative pressure, and collect the effluent;

[0041] Analyte recovery: 90-105%, relative standard deviation: less than 5%.

Embodiment 3

[0043] Object to be inspected: corn flour;

[0044] Types of mycotoxin contamination: trichothecenes;

[0045] Purification column packing configuration: packing 2.5g, including silica gel 1.8g, neutral alumina 0.45g, filter aid (Celite-hyflosuper-cell, Merck Chemical Technology (Shanghai) Co., Ltd.) 0.25g;

[0046] The purification method includes the following steps:

[0047] The first step is to prepare the sample solution, extract the analytes in the corn twice with 20ml of acetonitrile / water (v / v: 20 / 80) mixture, and combine the extracts;

[0048] The second step is to load the sample, take 2ml of the extract and add it to the purification column, and collect the effluent;

[0049] The third step is to elute with ethyl acetate as the eluent, flow through the purification column with 4ml of acetonitrile, suck dry under negative pressure, and collect the effluent;

[0050] Analyte recovery: 82-98%, relative standard deviation: less than 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com