Centrifugal machine for sewage treatment

A sewage treatment and centrifuge technology, applied in the field of centrifuges, can solve the problems of complicated sewage treatment procedures, time-consuming and laborious, and inconvenient for experimenters to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

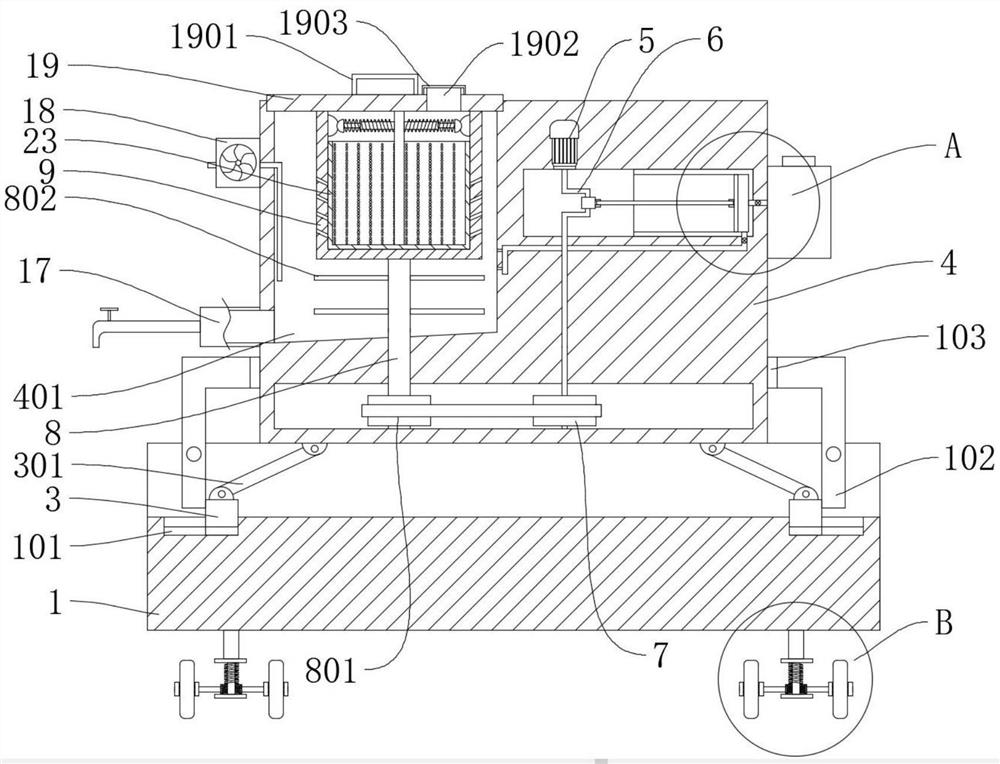

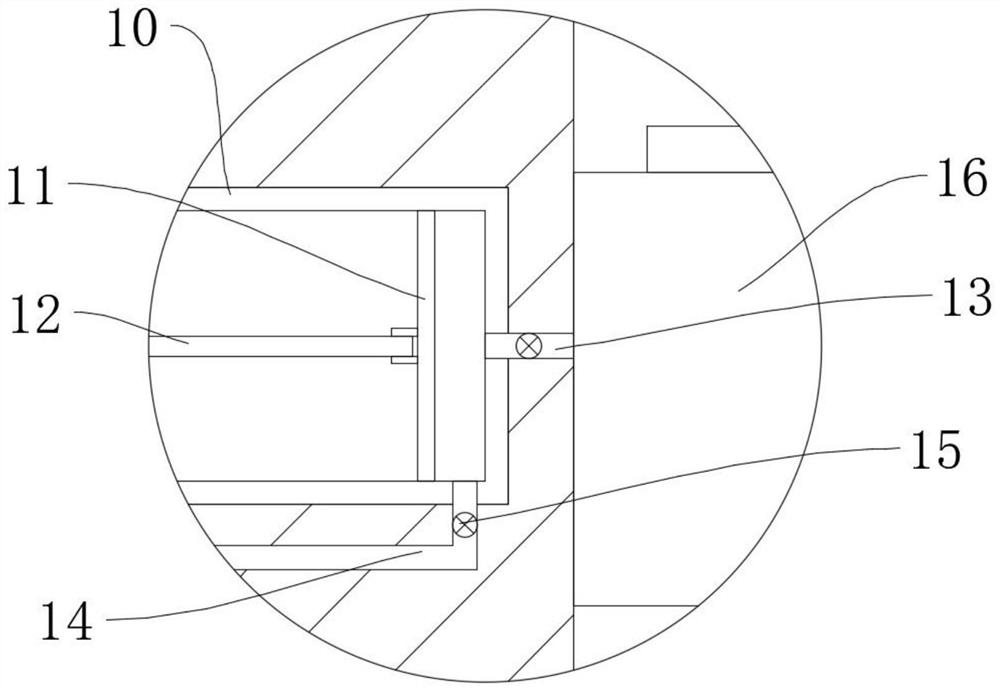

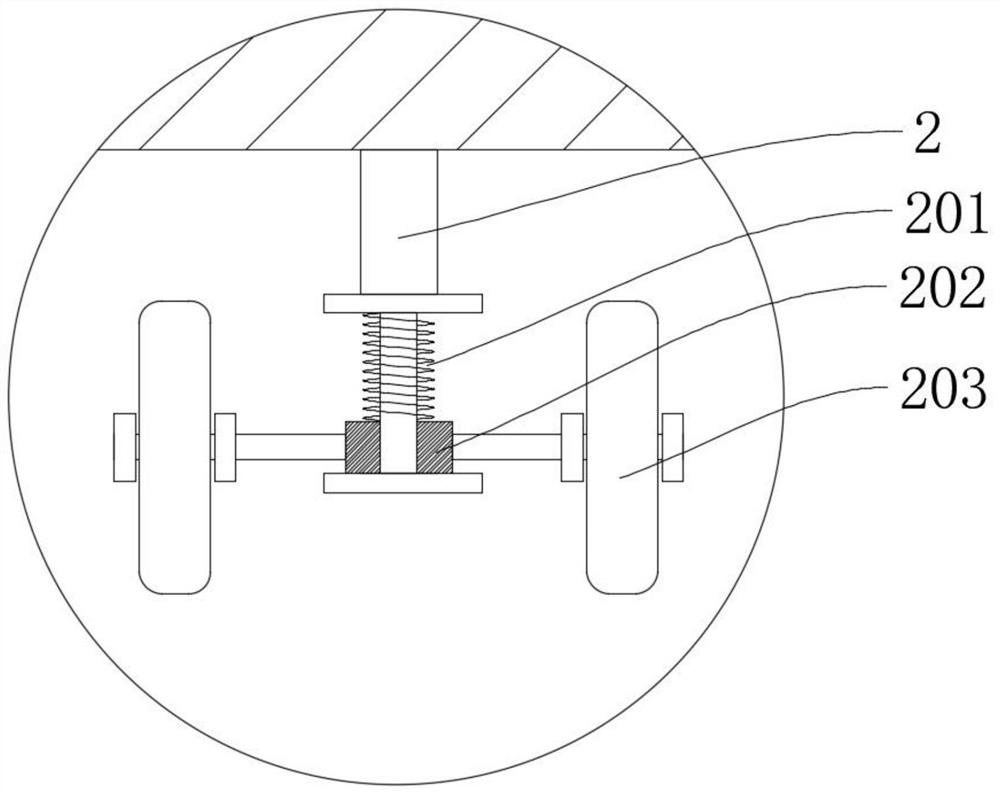

[0033] refer to Figure 1-8 , a centrifuge for sewage treatment, comprising a base 1 and a box body 4, the box body 4 is provided with a water collection cavity 401, a motor 5 is fixedly connected to the box body 4, and a crankshaft 6 and a first crankshaft 6 are fixedly connected to the output end of the motor 5 The pulley 7, the inner wall of the box body 4 is rotatably connected with a rotating shaft 8, the rotating shaft 8 is fixedly connected with a stirring tooth 802 and the drum 9, the inner wall of the box body 4 is fixedly connected with a piston cylinder 10, and the inner wall of the piston cylinder 10 is slidingly connected with a push plate 11, The outer wall of the push plate 11 is rotatably connected with a push rod 12, and the end of the push rod 12 away from the push plate 11 is rotatably connected to the crankshaft 6. The piston cylinder 10 is provided with a feed pipe 13 and a discharge pipe 14. The pipes 14 are provided with one-way valves 15, the box body 4...

Embodiment 2

[0047] refer to Figure 1-8 , a centrifuge for sewage treatment, comprising a base 1 and a box body 4, the box body 4 is provided with a water collection cavity 401, a motor 5 is fixedly connected to the box body 4, and a crankshaft 6 and a first crankshaft 6 are fixedly connected to the output end of the motor 5 The pulley 7, the inner wall of the box body 4 is rotatably connected with a rotating shaft 8, the rotating shaft 8 is fixedly connected with a stirring tooth 802 and the drum 9, the inner wall of the box body 4 is fixedly connected with a piston cylinder 10, and the inner wall of the piston cylinder 10 is slidingly connected with a push plate 11, The outer wall of the push plate 11 is rotatably connected with a push rod 12, and the end of the push rod 12 away from the push plate 11 is rotatably connected to the crankshaft 6. The piston cylinder 10 is provided with a feed pipe 13 and a discharge pipe 14. The pipes 14 are provided with one-way valves 15, the box body 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com