Rotating current hydrogen oxygen generator

A technology of rotating water flow, hydrogen and oxygen, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of increased power consumption, easy tempering, low gas output, etc., and achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

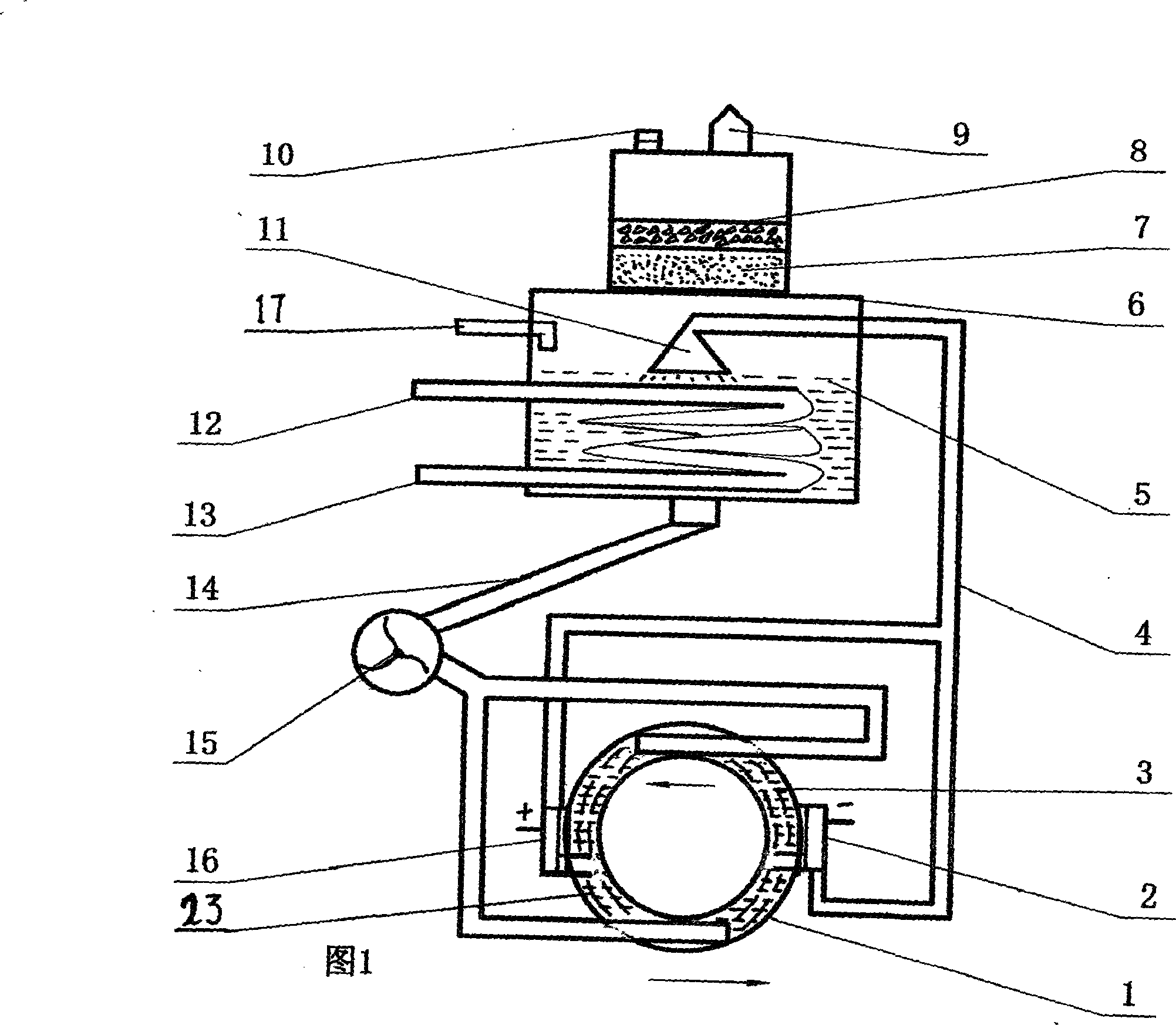

[0010] The embodiments are further described below in conjunction with the accompanying drawings.

[0011] Referring to Figure 1 and Figure 2, 1-electrolyzer, 2, cathode, 3-electrolyte, 4-heat-resistant insulating pipe, 5-cooling water, 6-water and gas separator, 7-sponge filter layer, 8-stainless steel Chip filter layer, 9-hydrogen oxygen outlet, 10-safety valve, 11-injection head, 12-cooling water inlet, 13-cooling water outlet, 14-heat-resistant insulating pipe, 15-water pump, 16-anode, 17-supplement Water inlet, 18-annular cylinder, 19-liquid level indicator tube, 20-barometer, 21-air pressure control electric switch, 22-water level control electric switch, 23-copper sheet. As shown in the figure, one of the innovative points of the present invention is to make the electrolytic cell into the shape of an annular pipe, and the cathode 2 and the anode 16 are arranged on both sides of it. In order to form a rotating water flow, a water pipe connected to the water pump 15 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com