Method for preparing heterogeneous water evaporation inhibitor

An evaporation inhibitor, heterogeneous technology, applied in chemical instruments and methods, reagents, other chemical processes, etc., can solve problems such as hindering the popularization and application of water evaporation inhibitors, loss of water evaporation effect, unstable performance, etc., to reduce The effect of water loss, reduction of water loss and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0016] Weigh 25 grams of petroleum ether (30-60° C.), add 3.6 grams of AEO-7 and 0.15 grams of AEO-2 compound emulsifiers, mix well, and use it as the oil phase. Weigh 25 grams of distilled water, and slowly drop the distilled water into the oil phase while stirring rapidly. After the dropwise addition, put the system into a numerically controlled ultrasonic cleaner to vibrate intermittently, each time for 30 seconds, and the interval between two vibrations is 10 seconds, and last for 10 minutes to obtain a stable W / O emulsion.

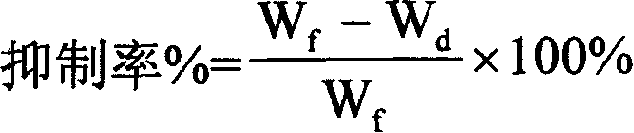

[0017] Take two identical porcelain plates with a surface area of 100cm 2 Left and right, inject 1000 grams of water respectively, add 30 microliters of emulsion to one porcelain plate, and not add to the other porcelain plate. After placing it at 30°C for 72 hours, weigh and calculate the water evaporation loss of the two porcelain plates, and use the formula Calculate the water evaporation inhibition rate of the system where the emulsion is sprea...

example 2

[0019] Weigh 0.625 g of n-butanol and fully dissolve it in 25 g of petroleum ether (30-60° C.), add 3.6 g of AEO-8 and 0.15 g of AEO-2 compound emulsifier, mix well, and use it as the oil phase. Weigh 25 grams of distilled water, and slowly drop the distilled water into the oil phase while stirring rapidly. After the dropwise addition, put the system into a numerically controlled ultrasonic cleaner to vibrate intermittently, each time for 30 seconds, and the interval between two vibrations is 10 seconds, and last for 10 minutes to obtain a stable W / O emulsion.

[0020] Take two identical porcelain plates with a surface area of 100cm 2 Left and right, inject 1000 grams of water respectively, add 30 microliters of emulsion to one porcelain plate, and not add to the other porcelain plate. After placing it at 30°C for 72 hours, weigh and calculate the water evaporation loss of the two porcelain plates, and use the formula Calculate the water evaporation inhibition rate of the s...

example 3

[0022] Weigh 1.25 g of cetyl alcohol and fully dissolve it in 25 g of petroleum ether (30-60° C.), add 3.6 g of AEO-9 and 0.15 g of AEO-2 compound emulsifier, mix well, and use it as the oil phase. Weigh 25 grams of distilled water, and slowly drop the distilled water into the oil phase while stirring rapidly. After the dropwise addition, put the system into a numerically controlled ultrasonic cleaner to vibrate intermittently, each time for 30 seconds, and the interval between two vibrations is 10 seconds, and last for 10 minutes to obtain a stable W / O emulsion.

[0023] Take two identical porcelain plates with a surface area of 100cm 2 Left and right, inject 1000 grams of water respectively, add 30 microliters of emulsion to one porcelain plate, and not add to the other porcelain plate. After placing it at 30°C for 72 hours, weigh and calculate the water evaporation loss of the two porcelain plates, and use the formula Calculate the water evaporation inhibition rate of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com