Improved ring shaped high-efficiency direct current arc welding machine

An arc welding machine, high-efficiency technology, applied in the field of arc welding machines, can solve the problems of the transformer current is too small, the primary coil current of the transformer is too large, and the transformer is easy to be damaged, so as to achieve good automatic current control, smooth pulsating voltage, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

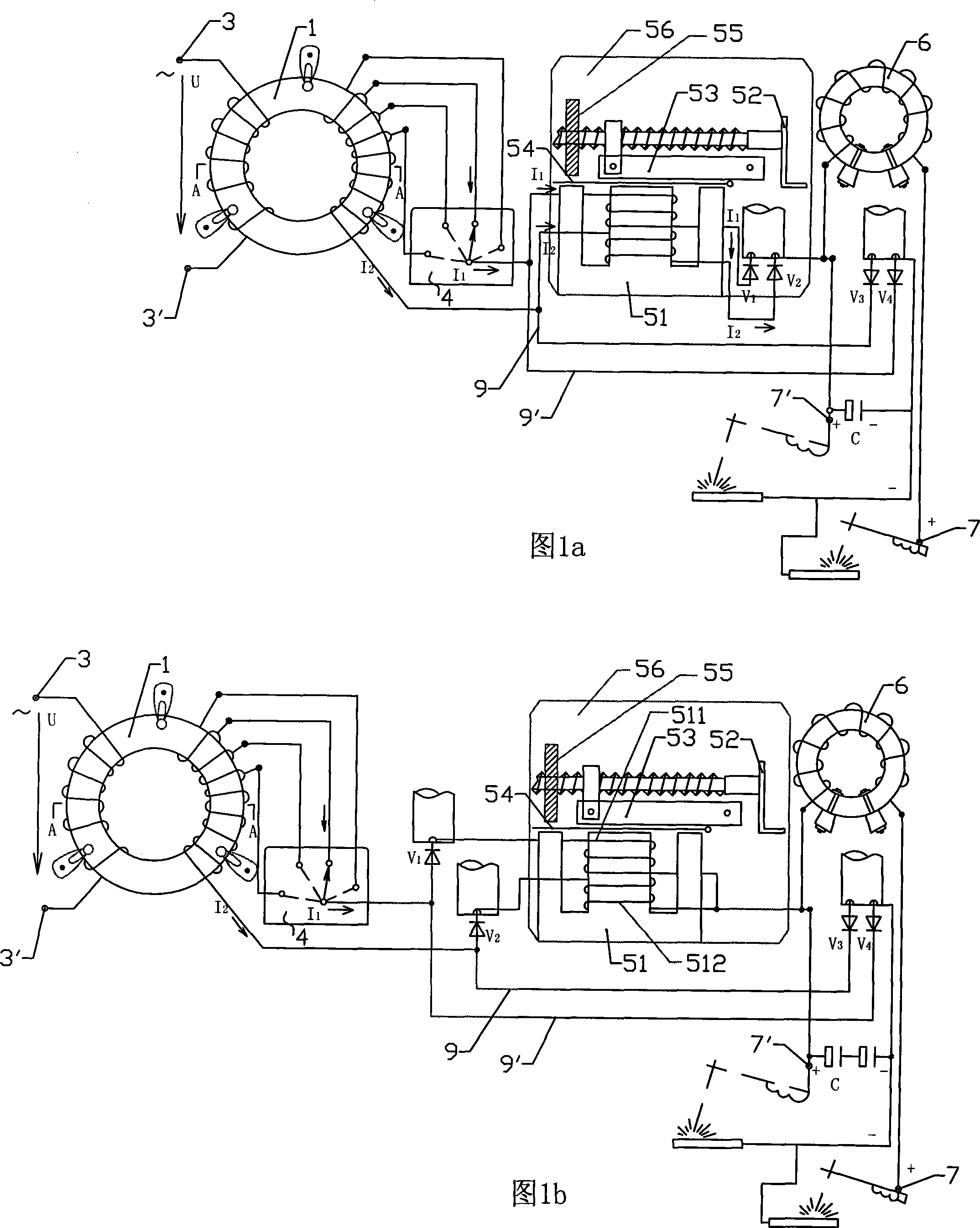

[0034] As shown in Figure 1a, this embodiment is a single-phase annular DC arc welding machine, and the reactor is connected between the output end of the annular transformer and the rectification circuit. The power supply input terminals 3, 3' are drawn from the two ends of the primary coil of the toroidal transformer, and the output terminals of the toroidal transformer are drawn from the secondary coil, wherein the lead wires of the output terminal of the positive half cycle are connected with the four input contacts of the voltage selection switch 4 in turn, from The winding wire 9' drawn from the output contact of the voltage selection switch 4 (that is, the lead wire of the positive half-axis output end of the transformer) and the lead wire 9 of the negative half-cycle output end of the toroidal transformer are respectively wound on the reactor core 51 in opposite directions, so that the reactor Two coils 511 and 512 wound in opposite directions are formed on the iron cor...

Embodiment 2

[0039] As shown in Fig. 1b, this embodiment is a single-phase annular DC arc welding machine, and two coils 511 and 512 wound in opposite directions on the reactor core are connected in series at the output end of the rectifier circuit. The structure and working principle of this embodiment are basically the same as those of Embodiment 1, except that the reactor is connected to the output end of the rectifier circuit, so no further description is given.

Embodiment 3

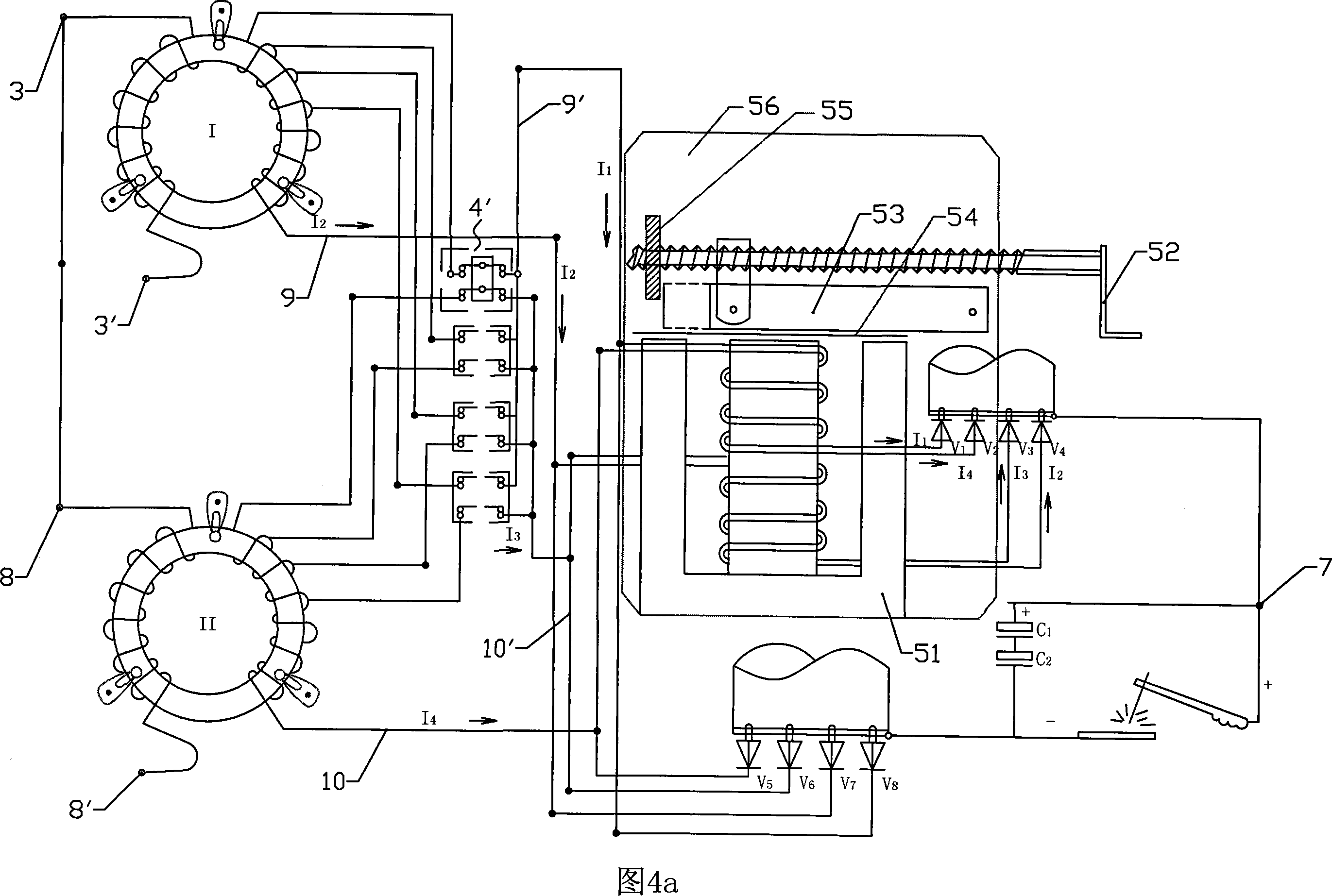

[0041] As shown in Figure 4a, this embodiment is a two-phase annular DC arc welding machine, and the reactor is connected between the output end of the toroidal transformer and the rectifier circuit; on the basis of Embodiment 1, a structure, material and winding are added For the same No. II toroidal transformer, another power supply input terminal 8, 8' is drawn from the primary coil of the toroidal transformer, and the output terminal of the transformer is similarly drawn from its secondary coil. The positive half-cycle output leads of the two transformers are connected to the input contacts of the voltage selection switch 4' one by one, and the output leads of the same level of voltage are connected to the same level of input contacts; at the output end of the voltage selection switch 4', the After the output contacts of the same group are connected in parallel, a winding wire is drawn out, which are the lead wire 9' of the positive half-cycle output end of No. I toroidal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com