Method of manufacturing bit tool used for cutting plastic film particle

A production method and plastic film technology, which is applied in the field of toothed cutter processing, can solve the problems of easy wire breakage, uneven cutting particles, and joint marks, etc., so as to achieve a dense and sharp metal structure on the tooth surface, and Precise layout and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

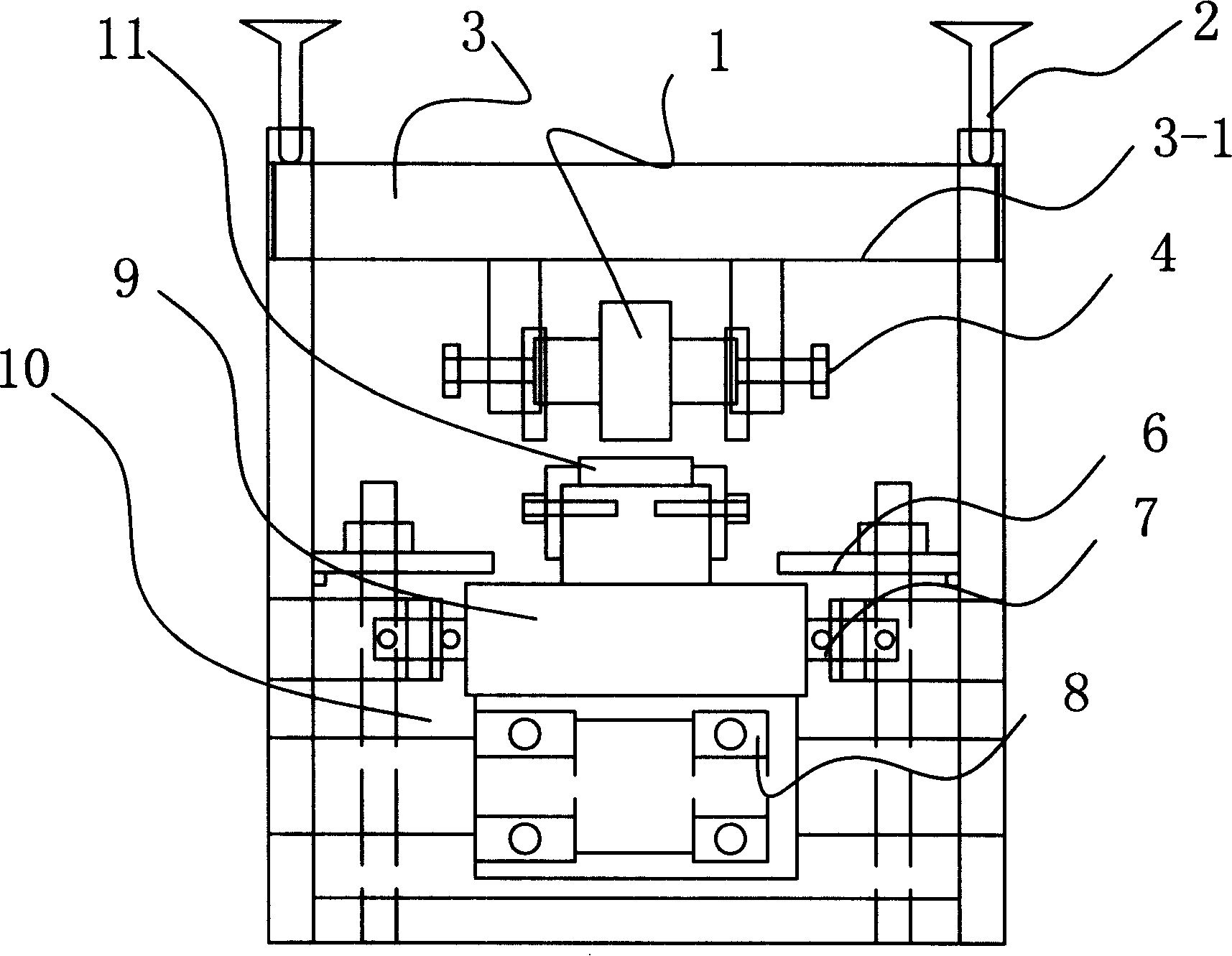

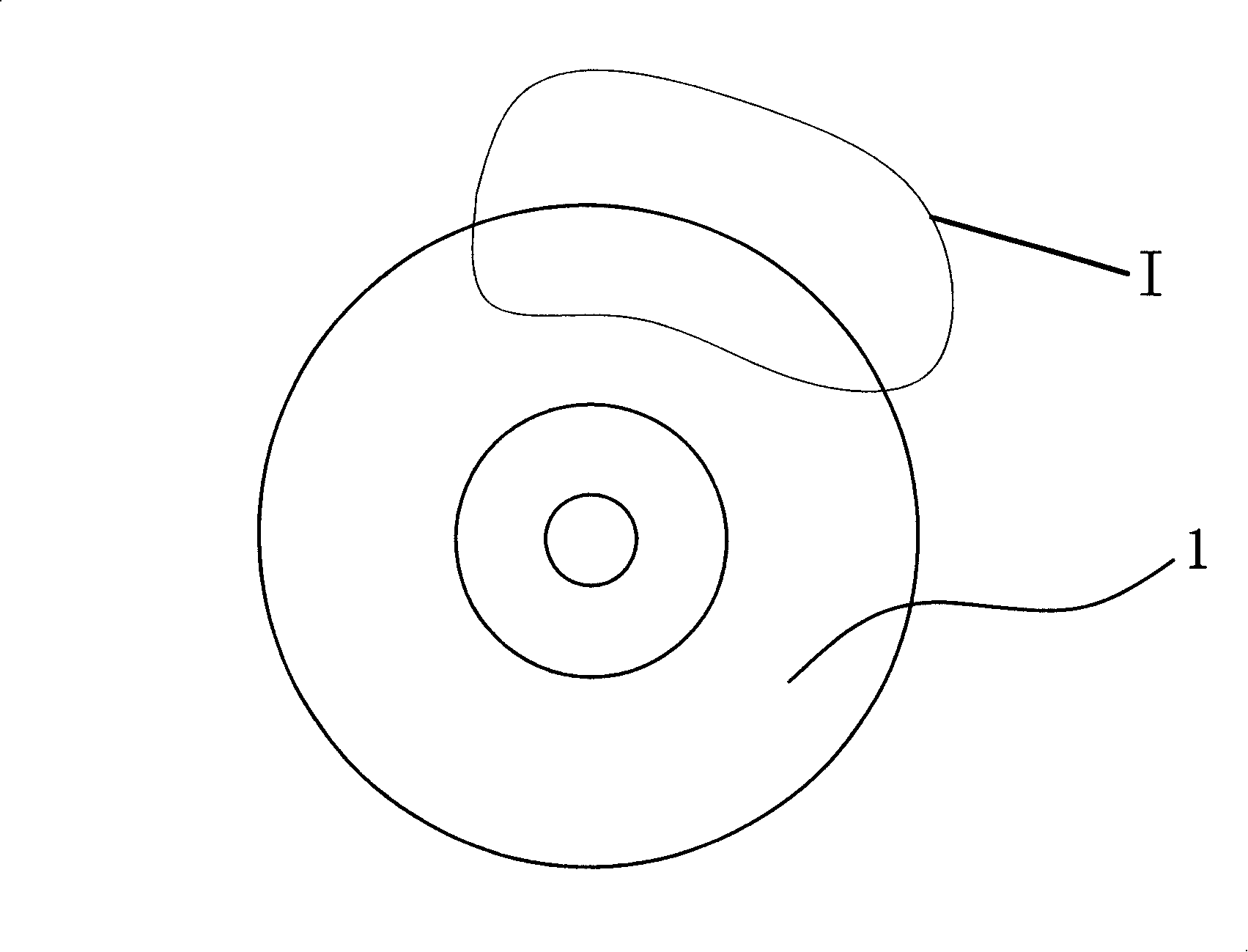

[0026] Example: such as figure 1 , 2, 3, 4, 5, 6, 7, the manufacturing device of the cutter shown, it comprises upper frame 3, underframe 10, is used to support the formwork 10 of metal block, is located on upper frame 3 and can rotate along the axis The outer surface of the rolling cylinder 1 with the required tooth shape, the mold frame 9 locks the metal block 11, the rolling cylinder 1 and the mold frame 9 are opposite up and down, and the mold frame 9 is connected with a translational mechanism Motor (not marked on the picture). The upper frame 3 has a beam 3-1, the rolling cylinder 1 is fixed under the beam 3-1, the two sides of the beam 3-1 are movable on the upper frame through the screw rod 2, and the adjusting screw rod 2 can be adjusted up and down The height of the rolling cylinder adjusts the distance between the rolling cylinder and the metal block, and the rolling cylinder 3 can rotate. The left and right sides of the formwork 9 are provided with limit bearings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com