Bubble wet processing dust container

A dust collector, wet technology, applied in chemical instruments and methods, dispersed particle separation, use of liquid separation agents, etc., can solve the problems of complex dust collector structure, reduced filtering effect, reduced suction efficiency, etc., to prolong the stay. time, improve the filter effect, improve the effect of the filter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

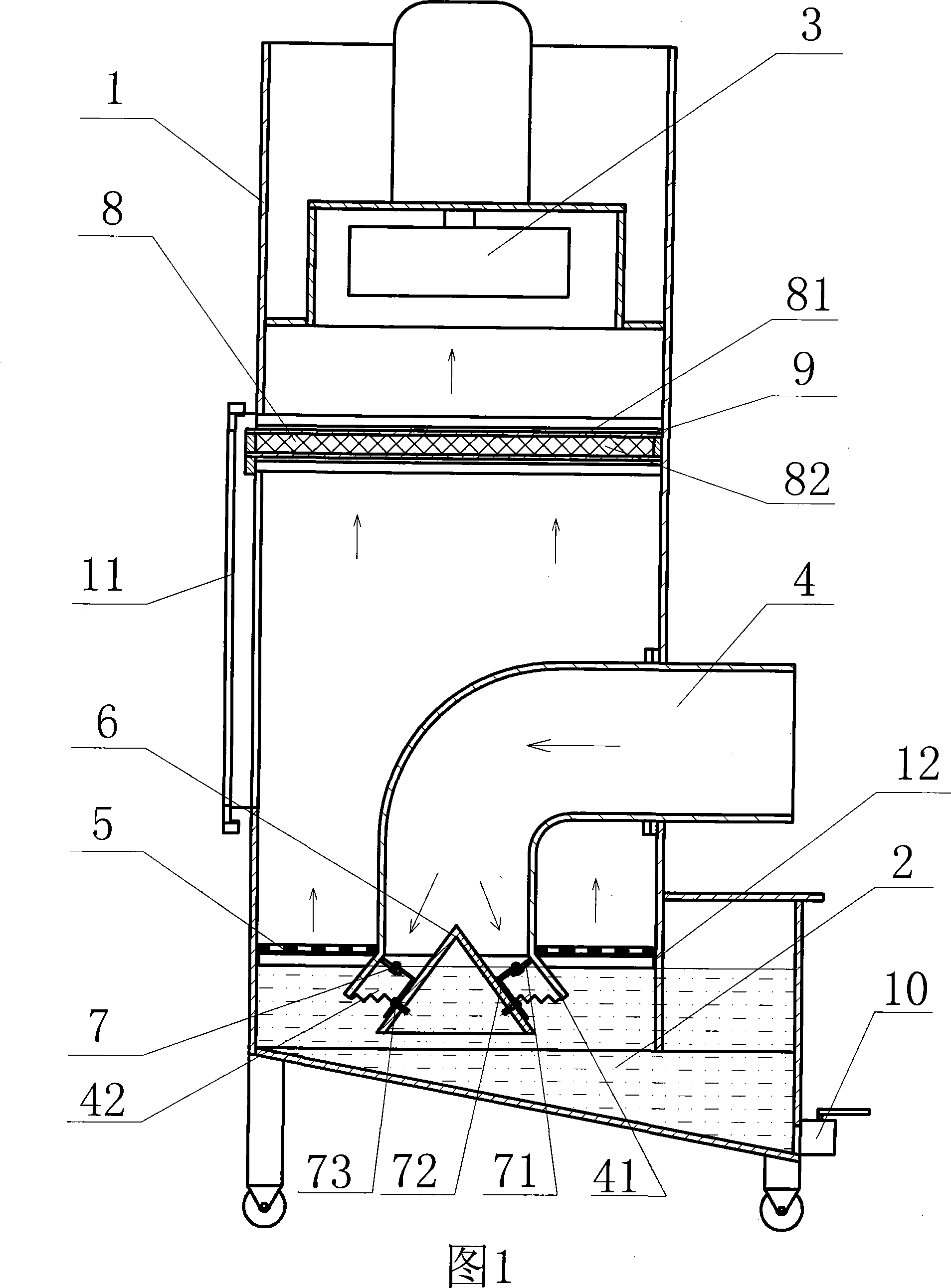

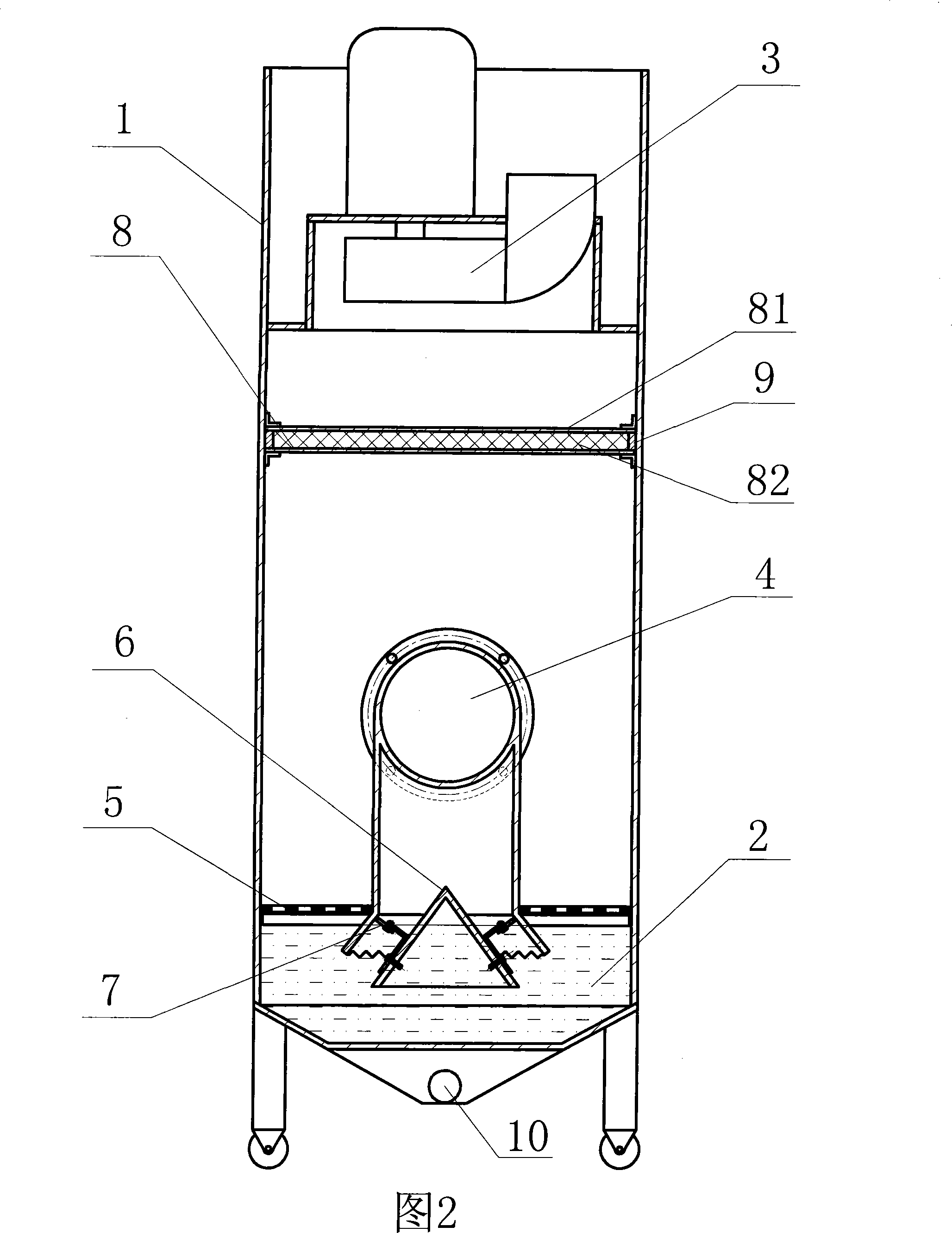

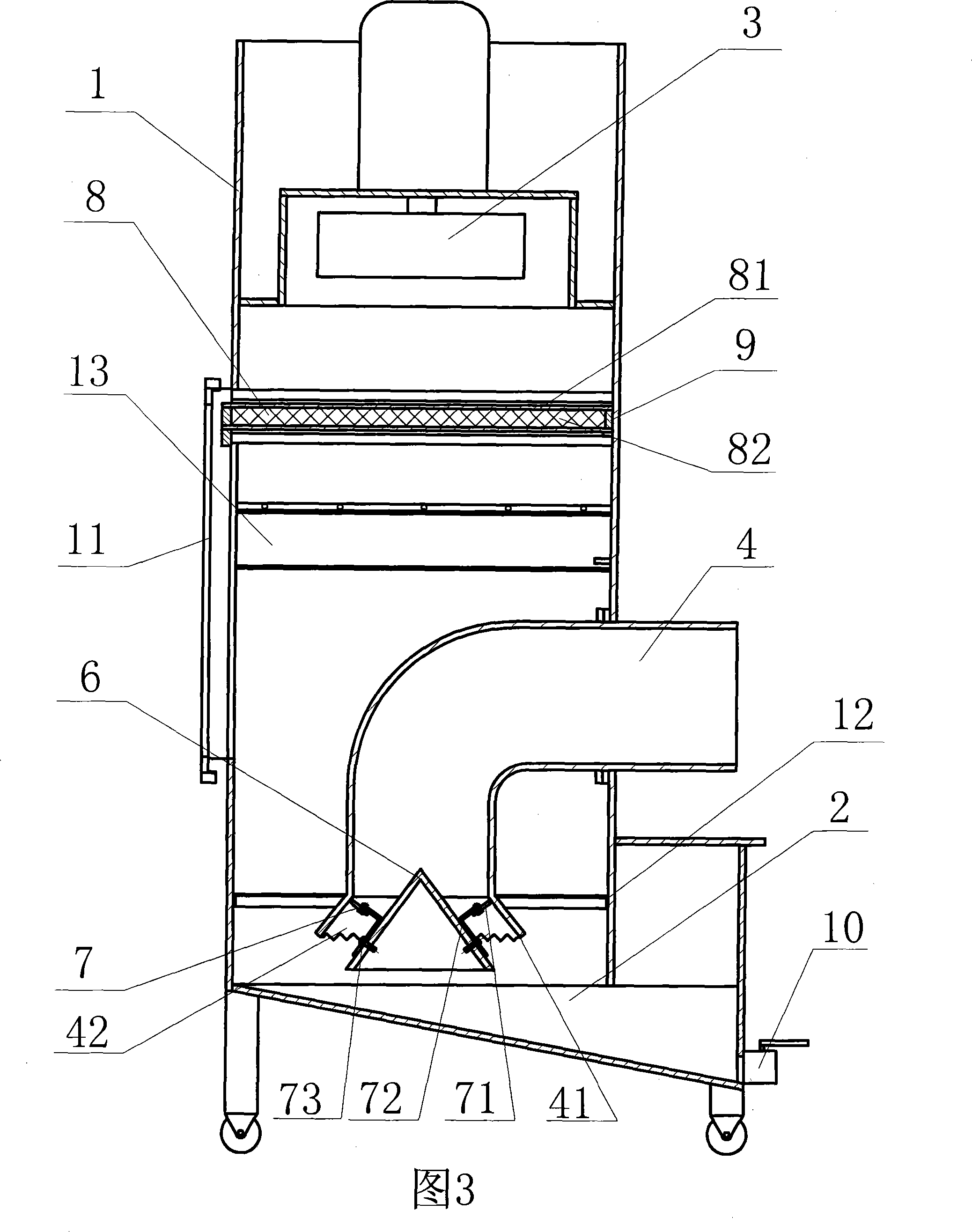

[0025] The bubble wet dust collector of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0026] As shown in Figures 1-2, the bubble wet dust collector of the present invention includes a box body 1, a water tank 2 arranged below the box body, and an air extractor 3 installed above the box body, and an air extraction bend is introduced at the upper position of the water tank 2. pipe 4, and fixed on the box body 1, a drain pipe 10 is installed under the water tank 2, and a door 11 is provided on the side of the box body 1, and a layer of evenly distributed perforated pipes is placed at the outlet end of the suction elbow 4 The mesh plate 5 is supported by the support bar 12 arranged on the inner periphery of the box body 1, and a filter plate 8 is also arranged above the suction elbow 4 near the air inlet of the air extractor 3, and the mesh plate 5 is arranged on the In the water tank 2 close to the working water surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com