Stirring fan component of microwave oven

A technology for microwave ovens and components, applied in the field of microwave ovens, can solve problems such as defectiveness and easy occurrence of ignition, and achieve the effect of complete matching and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

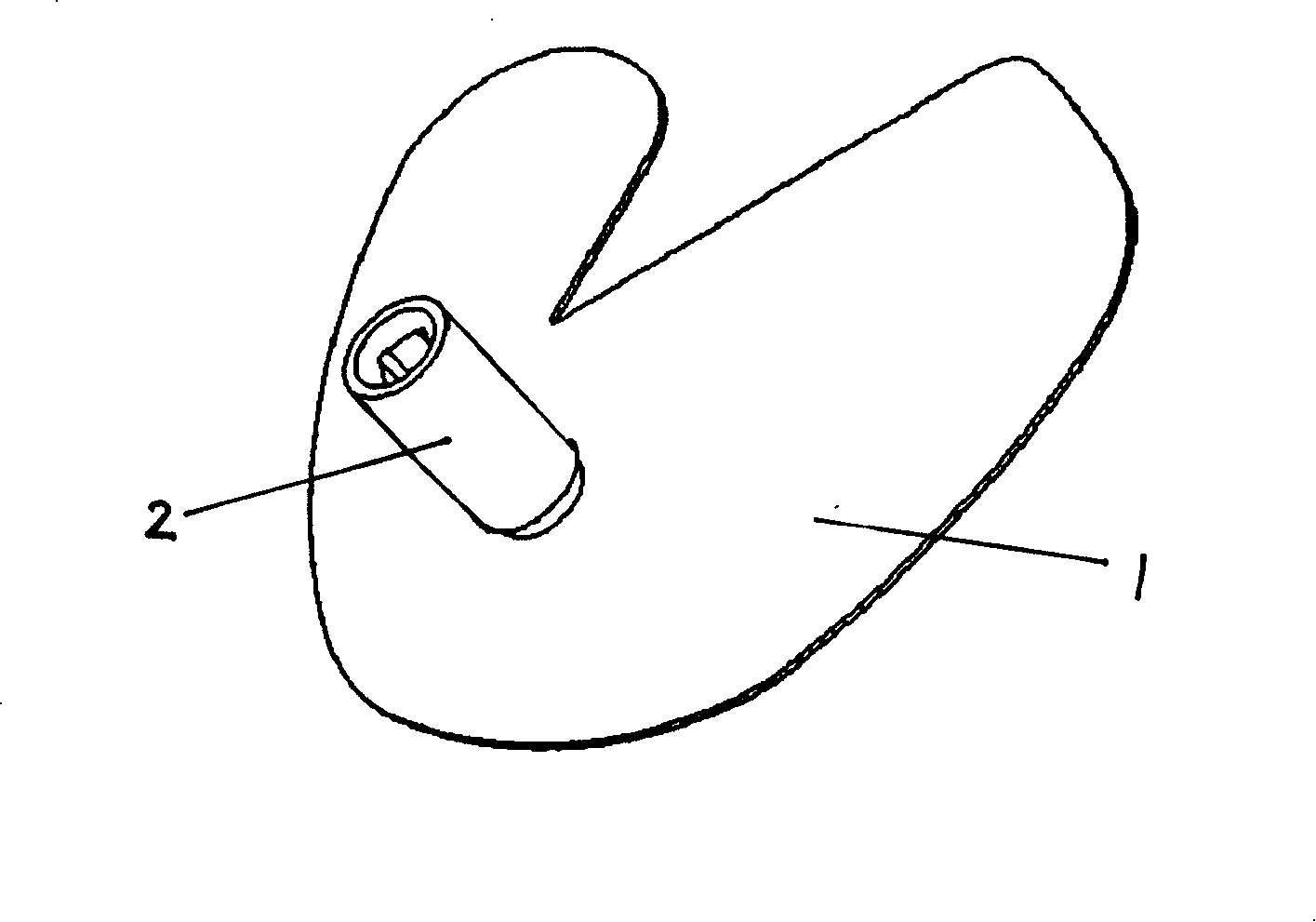

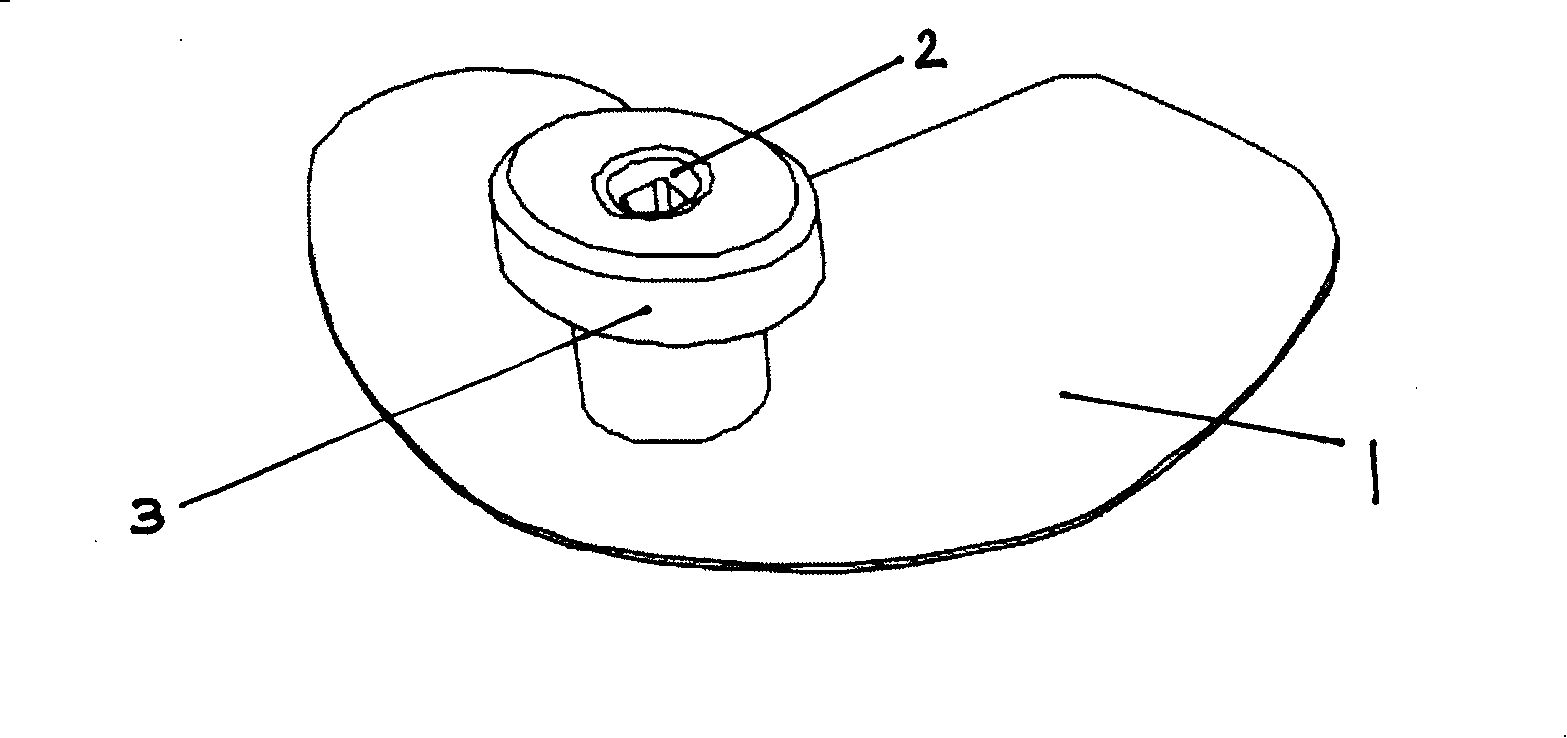

[0010] The stirring fan assembly of the microwave oven of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0011] Such as figure 2 As shown, the stirring fan assembly of the microwave oven of the present invention includes a stirring fan blade 1 and a stirring fan shaft 2, and a Teflon bushing 3 (Teflon) is added to the stirring fan shaft 2 . The Teflon bushing 3 is a stepped cylinder.

[0012] Because Teflon has good wear resistance, heat resistance and microwave reflection characteristics, a Teflon ring is placed on the shaft of the stirrer, so that part of the microwave in the waveguide will be reflected by the Teflon ring when it enters the furnace body, which can be well improved. Distribution of microwaves. Make the matching between the magnetron and the furnace body intact, no sparking phenomenon, and the sparking rate is 0.

[0013] The change of shape of Fron bushing 3 is simple and eas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com