Metallurgical extraction method for molybdenum-tungsten oxide bulk concentrate

A technology of mixing concentrate and extraction method, applied in the direction of improving process efficiency, can solve the problems of low technical and economic indicators, high recovery cost, no recycling, etc., and achieve the effect of simple process, few steps, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

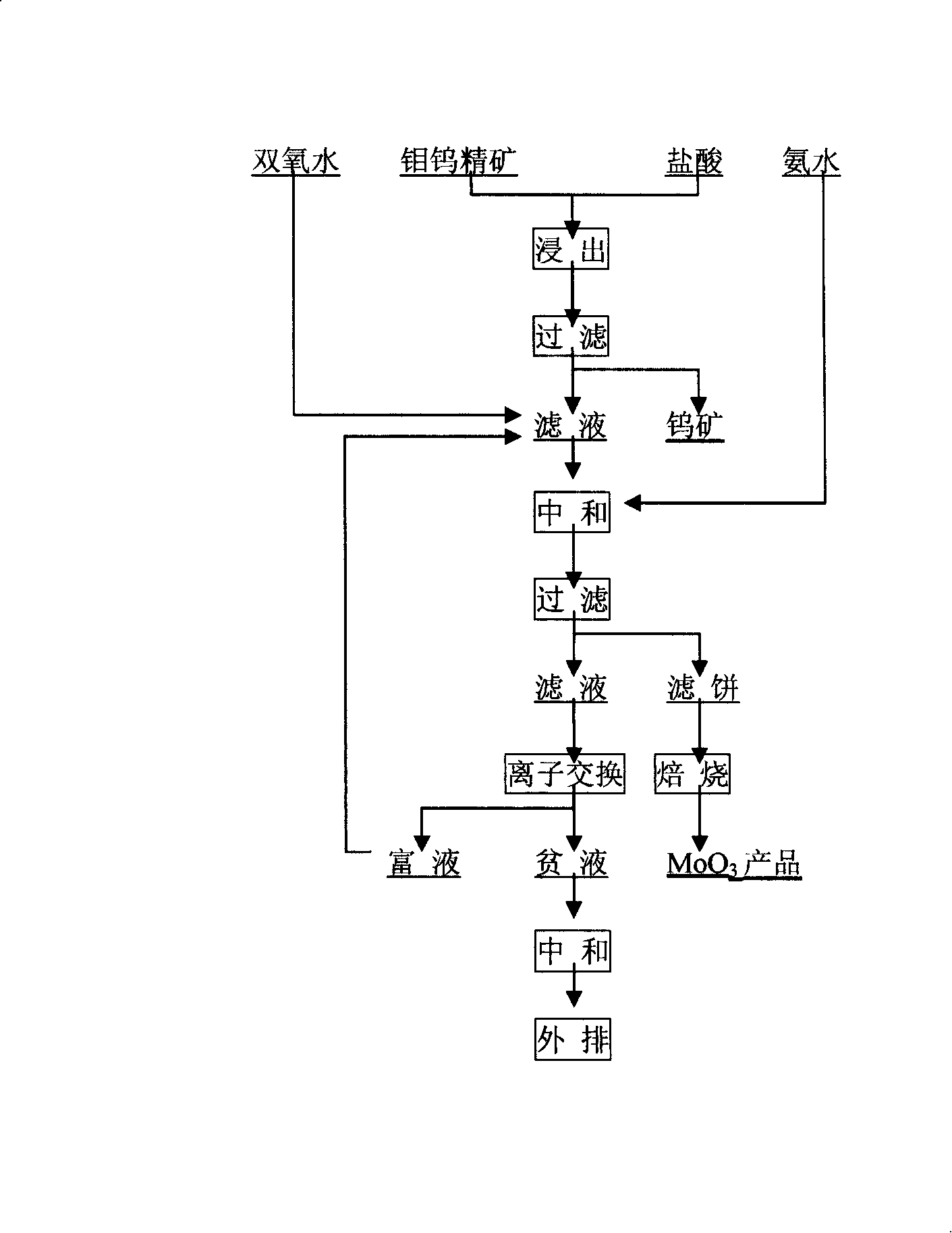

[0024] As shown in the figure, the process of the present invention includes four steps of leaching, oxidation, neutralization and roasting, and the process flow is as follows:

[0025] A. Leaching

[0026] Using molybdenum tungsten oxide ore as raw material, add acid for leaching in the stirring tank covered with acid-proof lining, control the liquid-solid ratio after adding acid between 1:1, control the acid concentration at 50g / L, and leaching The temperature is between 20°C and the reaction time is 1 hour. After the reaction is completed, filter, the molybdenum content in the filtrate is 80g / L, and the washed filter residue is crude tungsten concentrate with increased tungsten content;

[0027] B. Oxidation

[0028] Adding an oxidant to oxidize the low-valent molybdenum to high-valent molybdenum, the weight ratio of the oxidant to the raw material is 1:100;

[0029] C. Neutralize

[0030] Control the neutralization temperature at 20°C, and slowly add 10% ammonium salt a...

Embodiment 2

[0035] As shown in the figure, the process of the present invention mainly includes four steps of leaching, oxidation, neutralization and roasting, and the process flow is as follows:

[0036] A. Leaching

[0037] Using molybdenum tungsten oxide ore as raw material, add acid for leaching in a stirring tank covered with acid-proof lining, control the liquid-solid ratio after adding acid between 1:2, control the acid concentration at 100g / L, and leaching The temperature is between 30°C and the reaction time is 3 hours. After the reaction is completed, filter, the molybdenum content in the filtrate is 90g / L, and the washed filter residue is crude tungsten concentrate with increased tungsten content;

[0038] B. Oxidation

[0039] Adding an oxidizing agent to oxidize the low-valent molybdenum to high-valent molybdenum, the weight ratio of the oxidizing agent to the raw material is 2:100;

[0040] C. Neutralize

[0041] Control the neutralization temperature at 30°C, and slowly ...

Embodiment 3

[0046] As shown in the figure, the process of the present invention mainly includes four steps of leaching, oxidation, neutralization and roasting, and the process flow is as follows:

[0047] A. Leaching

[0048] Using molybdenum tungsten oxide ore as raw material, add acid for leaching in a stirring tank covered with acid-proof lining, control the liquid-solid ratio after adding acid between 1:2~, and control the acid concentration at 150g / L, The leaching temperature is between 50°C and the reaction time is 5 hours. After the reaction is completed, filter, the molybdenum content in the filtrate is 100g / L, and the washed filter residue is crude tungsten concentrate with increased tungsten content;

[0049] B. Oxidation

[0050] Adding an oxidizing agent to oxidize the low-valent molybdenum to high-valent molybdenum, the weight ratio of the oxidizing agent to the raw material is 5:100;

[0051] C. Neutralize

[0052] Control the neutralization temperature at 40°C, and slowl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com