Method for producing d-pseudoephedrine by microbe transformation process

A technology of microbial transformation and pseudoephedrine, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of cost and environmental protection unfavorable promotion, and achieve environmental protection, reduce production costs, and strong specificity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

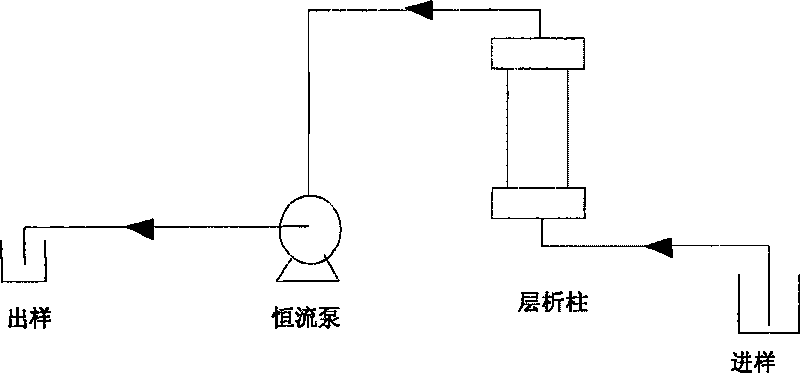

Method used

Image

Examples

Embodiment 1

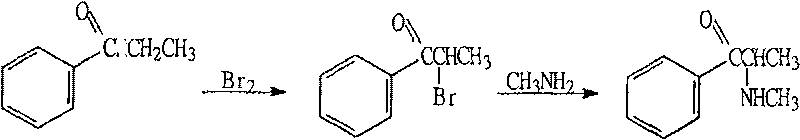

[0027] Embodiment 1: the synthesis of 1-phenyl-2-methylaminoacetone

[0028] The synthetic reaction formula of 1-phenyl-2-methylaminoacetone is:

[0029]

[0030] Put 40.0g propiophenone (0.30moL) and 120mL 1,2-dichloroethane into a 500mL Erlenmeyer flask, and add bromine 48.0g (0.30mol) dropwise under stirring at room temperature so that the reaction solution just fades. After dripping the bromine, react for half an hour, transfer the reaction solution to a separatory funnel, and wash the reaction solution twice with water (150 mL each time). The organic phase was separated and the aqueous phases were combined. The aqueous phase was washed twice with dichloroethane (40 mL each). Combine the organic phases, distill under reduced pressure, and collect fractions at 128-130°C / 10-11mmHg.

[0031] Add 19 mL of benzene and 19.4 mL of methylamine aqueous solution (containing about 0.13 mol CH 3 NH 2 ), constant temperature in a water bath at 40°C, 12.6g of α-bromopropiophenon...

Embodiment 2

[0032] Embodiment 2: the cultivation and thalline collection of Morganella morganii

[0033] Shake flask seed culture: add 40mL medium in 250mL Erlenmeyer flask, medium composition (mass percentage): glucose 2.0%, yeast extract 0.35%, peptone 2.0%, K 2 HPO 4 0.2%, MgSO 4 ·7H 2 O0.01%, NaCl 0.1%, the initial pH of fermentation is 7.0, and the inoculum size is 5%. The rotation speed of the shake flask was 150 rpm, the culture temperature was 37° C., and the culture time was 42 hours.

[0034] Fermenter expansion cultivation: fermenter body volume 5L, medium volume 3L, medium composition (mass percentage): glucose 3.5%, yeast extract 0.55%, peptone 3.5%, K 2 HPO 4 0.4%, MgSO 4 ·7H 2 O 0.03%, NaCl 0.3%, initial pH 7.0. The inoculum size was 450 mL, the stirring speed was 150 r / min, the ventilation rate was 1:0.2 v / v / m, the culture temperature was 35° C., and the culture time was 50 hours.

[0035] The fermented liquid obtained by the expanded culture was centrifuged under...

Embodiment 3

[0036] Embodiment 3: the cultivation and thalline collection of Morganella morganii

[0037] Shake flask seed culture is the same as in Example 2.

[0038] Fermenter expansion cultivation: fermenter body volume 10L, medium volume 6L, medium composition (mass percentage): glucose 3.5%, yeast extract 0.55%, peptone 3.5%, K 2 HPO 4 0.4%, MgSO 4 ·7H 2 O0.03%, NaCl0.3%, initial pH is 7.0. The inoculum volume was 850 mL, the stirring speed was 80 r / min, the ventilation rate was 1:0.5 v / v / m, the culture temperature was 36° C., and the culture time was 44 hours.

[0039] Secondary expansion culture of fermenter: the volume of fermenter is 500L, and the volume of medium is 350L. The culture medium consists of (mass percentage): glucose 3.0%, yeast extract 0.5%, peptone 2.5%, K 2HPO 4 0.3%, MgSO 4 ·7H 2 O 0.02%, NaCl 0.2%, starting pH 7.0. The inoculum size was 37 L, the stirring speed was 100 r / min, the ventilation rate was 1:0.3 v / v / m, the culture temperature was 37° C., and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com