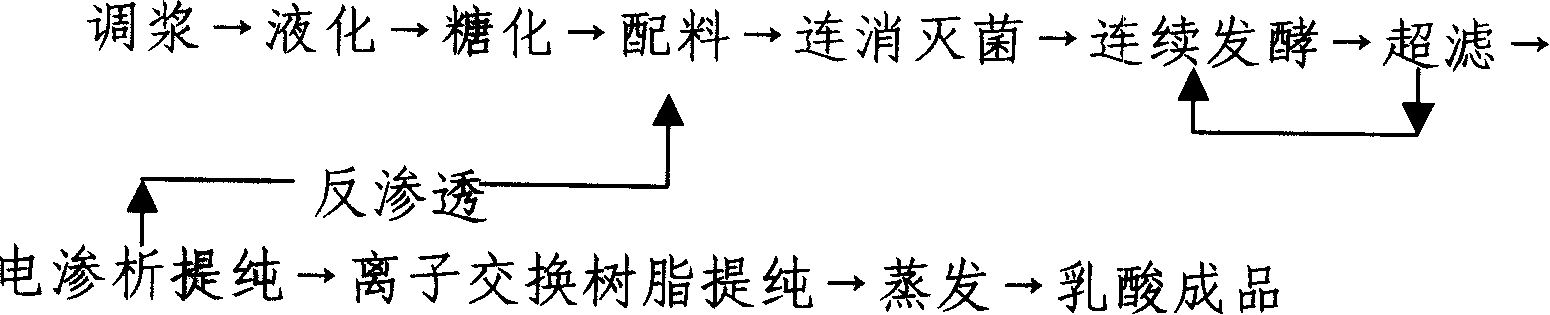

Method for producing lacitc acid by non-calcium autocycle continuous fermentation salt fermentation

A technology of automatic circulation and calcium salt method, applied in the biological field, can solve the problems of long process flow, low yield, low conversion rate, etc., and achieve the effects of prolonging metabolism time, improving fermentation efficiency and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, the non-calcium salt method automatic cycle continuous fermentation process for producing lactic acid comprises the following steps:

[0039] 1. Slurry preparation: first adjust 950kg cornstarch to a concentration of 30% by weight at a temperature of 50°C, pH 6.0, and the amount of amylase to be 12u / g.

[0040] 2. Liquefaction: The temperature is controlled at 98°C, the time is 30 minutes, and the DE value is controlled at 18.

[0041] 3. Saccharification: the temperature is controlled at 60°C, the pH value is 4.5, the time is 30 hours, the DE value is 95, and the amount of glucoamylase used is 80u / g.

[0042] 4. Ingredients: The five kinds of ABCDE medium formulas used in the present invention are in different fermentation stages, and the temperature of the medium is all controlled at 60° C., and the pH value is 6.

[0043] Medium formula A is: glucose 150kg / m 3 , ammonium lactate ≤ 1.5%, WPH 5kg / m 3 , NH 4 h 2 PO 4 0.5kg / m 3 , KH 2 PO 4 ...

Embodiment 2

[0056] The basic process is the same as in Example 1, except that the pulping process is as follows: the starch concentration is controlled at 25%, the temperature is 60°C, the pH is 6.5, and the amount of amylase is 8u / g.

[0057] The liquefaction process is as follows: the temperature is controlled at 100°C, the time is 40 minutes, and the DE value is controlled at 15.

[0058] The saccharification process is as follows: the temperature is controlled at 62°C, the pH value is 4.8, the time is 40 hours, the DE value is 98, and the amount of saccharification enzyme used is 150u / g.

[0059] Medium formula A is: glucose 120kg / m 3 , sodium lactate ≤ 1.5%, WPH 8kg / m 3 , NH 4 h 2 PO 4 1.5kg / m 3 , KH 2 PO 4 0.9kg / m 3 , MgSO 4 ·7H 2 O 0.5kg / m 3 , MnSO 4 ·H 2 O 0.05kg / m 3 . Prepare with sterile deionized water.

[0060] The difference between medium B and medium A is: WPH 10kg / m 3 , KH 2 PO 4 0.05kg / m 3 .

[0061] The composition of medium C is basically the sam...

Embodiment 3

[0066] The basic process is the same as in Example 1, except that the pulping process is as follows: the starch concentration is controlled at 28%, the temperature is 55°C, the pH is 6.2, and the amount of amylase is 15u / g.

[0067] The liquefaction process is as follows: the temperature is controlled at 105°C, the time is 35 minutes, and the DE value is controlled at 22.

[0068] The saccharification process is as follows: the temperature is controlled at 60°C, the pH value is 4.6, the time is 35 hours, the DE value is 96, and the amount of glucoamylase used is 120u / g.

[0069] Medium formula A is: glucose 60kg / m 3 , potassium lactate ≤1.5%, WPH 10kg / m 3 , NH 4 h 2 PO 4 1.0kg / m 3 , KH 2 PO 4 1.0kg / m 3 , MgSO 4 ·7H 2 O 0.6kg / m 3 , MnSO 4 ·H 2 O 0.01kg / m 3 . Prepare with sterile deionized water.

[0070] The difference between medium B and medium A is: WPH 15kg / m 3 , KH 2 PO 4 0.01kg / m 3 .

[0071] The composition of medium C is basically the same as tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com