Catalyst for hydrogen production from methane vapor reforming and preparing method thereof

A methane water vapor, reforming hydrogen production technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of catalytic activity and stability that cannot be well satisfied, and achieve the improvement of catalytic activity and stability, Effects of increased specific surface area and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Ni / Ce 0.25 Zr 0.75 o 2 Particle catalyst, the preparation method is as follows:

[0033](1) Ce(NO 3 ) 3 ·6H 2 O, Zr(NO 3 ) 3 ·3H 2 O is dissolved in metered deionized water to form a solution with a concentration of 0.5mol / L;

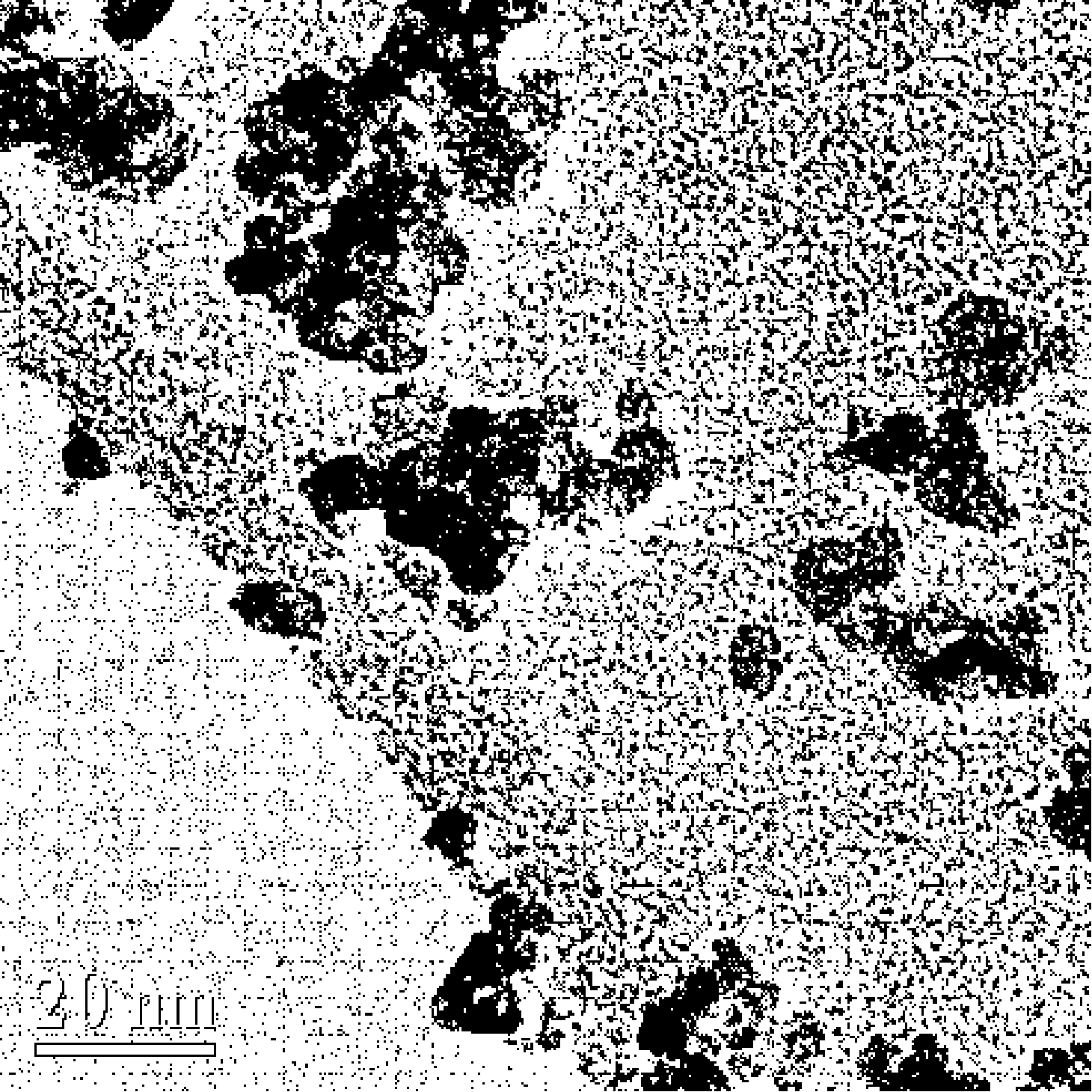

[0034] (2) Dilute industrial ammonia water with a concentration of 25% twice as a precipitating agent, add the salt solution obtained in (1) dropwise to the precipitating agent under continuous stirring, control the pH=9, after the precipitation is complete, let it stand at room temperature After 12 h, wash twice with deionized water, replace the water in the resulting precipitate with absolute ethanol, supercritically dry, and roast at 800 °C for 6 h to obtain Ce 0.25 Zr 0.75 o 2 Nano-cerium-zirconium composite oxide support, characterized by TEM, such as figure 1 As shown, the particle diameter of the carrier is 5-20nm, mostly 5-10nm;

[0035] (3) Ni(NO 3 ) 3 ·6H 2 O was dissolved in metered deionized water, and the prepared car...

Embodiment 2

[0038] Ni / Ce 0.25 Zr 0.75 o 2 Monolithic catalyst, the preparation method is as follows:

[0039] Steps (1), (2) and (3) are the same as in Example 1, weighing 10 g of catalyst powder, adding 10 ml of deionized water, and ball milling for 12 hours to prepare a catalyst slurry with a solid content of 30%-60%. Make a 400cpsi cordierite ceramic honeycomb carrier into a cylinder with a length of 10mm, a width of 10mm, and a height of 30mm. Put the blank substrate into the catalyst slurry and immerse it for 5min. After taking it out, blow off the excess slurry on the substrate with compressed air , dried at 100°C for 12h and calcined at 500°C for 10h to obtain Ni / Ce 0.25 Zr 0.75 o 2 Monolithic catalyst for hydrogen production by steam reforming of methane. It was loaded into a fixed-bed quartz reactor to evaluate the activity and stability of the catalyst, and the methane conversion rate reached 97.8% at 750°C.

Embodiment 3

[0041] Ni-Ru / MgO-Ce 0.143 Zr 0.857 o 2 Particle catalyst, the preparation method is as follows:

[0042] (1) Ce(NO 3 ) 3 ·6H 2 O, Zr(NO 3 ) 3 ·3H 2 O is dissolved in metered deionized water to form a solution with a concentration of 0.5mol / L;

[0043] (2) Dilute the industrial ammonia water with a concentration of 25% twice as a precipitating agent, add the salt solution obtained in (1) dropwise to the above precipitating agent under continuous stirring, control the pH=8, after the precipitation is complete, let it stand at room temperature After 12 h, wash with deionized water for 3 times, replace the water in the resulting precipitate with absolute ethanol, supercritically dry, and roast at 650 ° C for 6 h to obtain Ce 0.143 Zr 0.857 o 2 Nano-cerium-zirconium composite oxide carrier, characterized by TEM, the particle diameter of the carrier is 5-20nm, most of which are 5-10nm;

[0044] (3) dissolving nickel oxalate whose nickel content is 5% of catalyst mass in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com