Prefabricated branch cable manufacturing method

A manufacturing method and technology of prefabricated branches, applied in cable/conductor manufacturing, insulated cables, cables, etc., can solve problems such as violation of technical specifications and cannot be used casually, and achieve the effects of improving sealing effect, firm wire clamping, and simple processing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

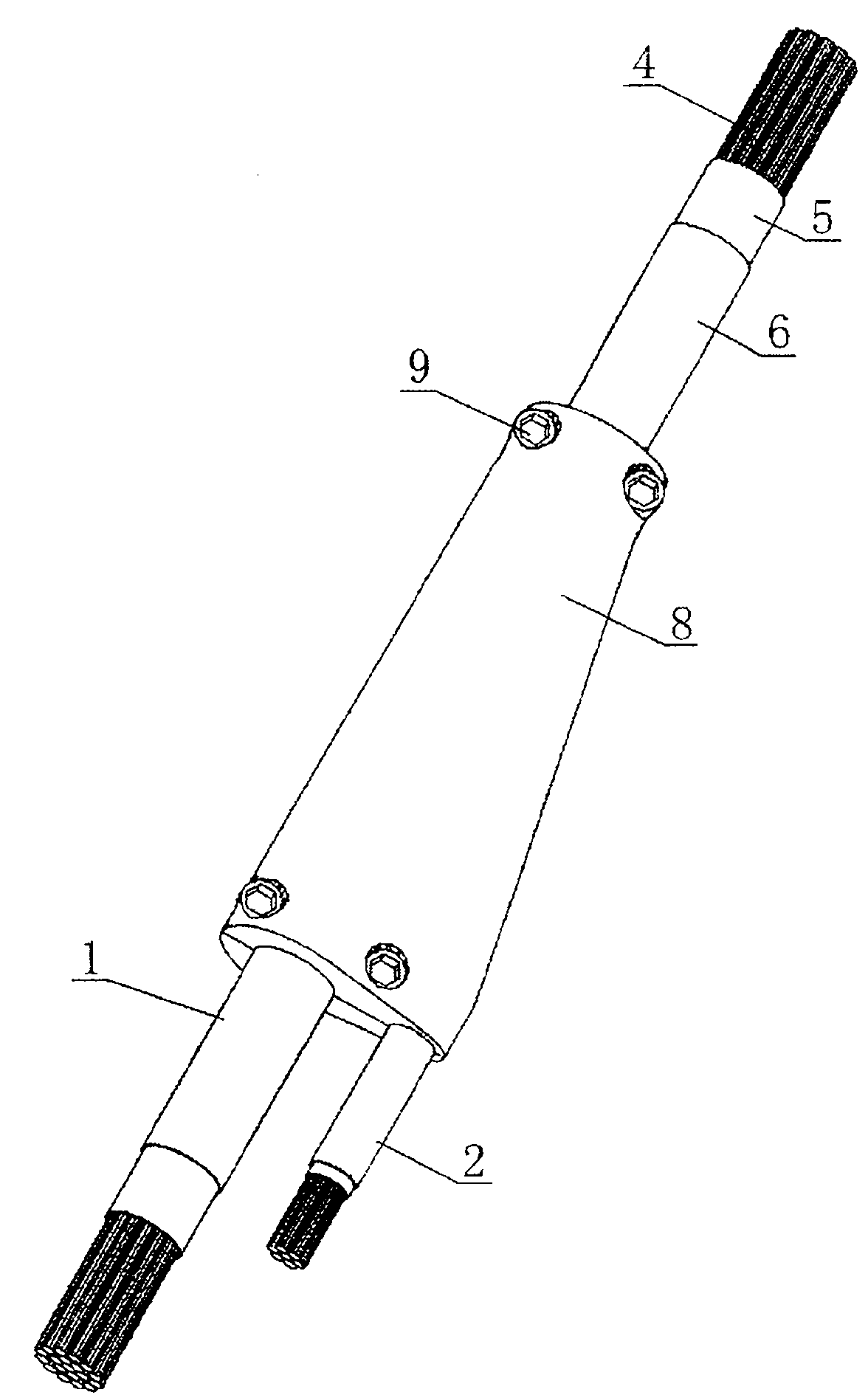

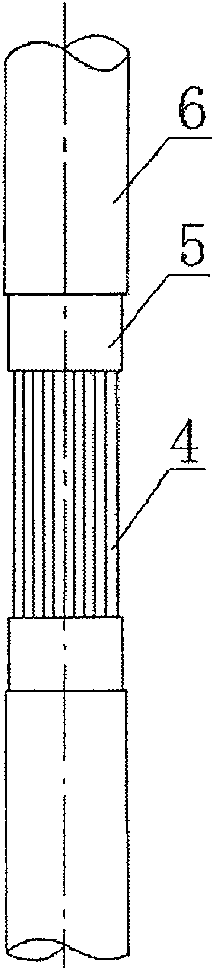

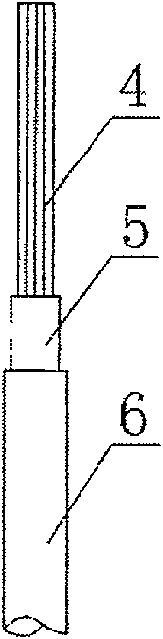

[0034] The embodiment is shown in FIGS. 4-5 . In this prefabricated branch cable, both the trunk line 1 and the branch line 2 are composed of a conductor 4 , an insulating layer 5 and a metal sheath 6 . The conductor 4 can be formed by twisting one or more metal wire cores. The insulating layer 5 is formed by winding a mineral insulating tape, and the mineral insulating tape can be a single inorganic material insulating tape or a mixed inorganic material insulating tape made of glass fiber, mica tape, asbestos silk, or metal oxide. The surface of the metal sheath 6 can be smooth or corrugated.

[0035] The wires of the main line 1 and the branch line 2 are connected in a Y shape, and the mineral insulating tape is wrapped around the nodes, and they are crimped together by the connector 3. The outermost layer is closed by a metal cover 7 and a metal cover 8, and the metal cover Both the shell 7 and the metal cover 8 have corresponding connection holes 15 and are fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com