No-leakage structure of steel reinforced concrete pool and well, and leakage preventing method

A reinforced concrete and concrete technology, applied in swimming pools, building components, public buildings, etc., can solve problems such as only treating the symptoms but not the root cause, and ignoring the potential of the reinforced concrete structure itself.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

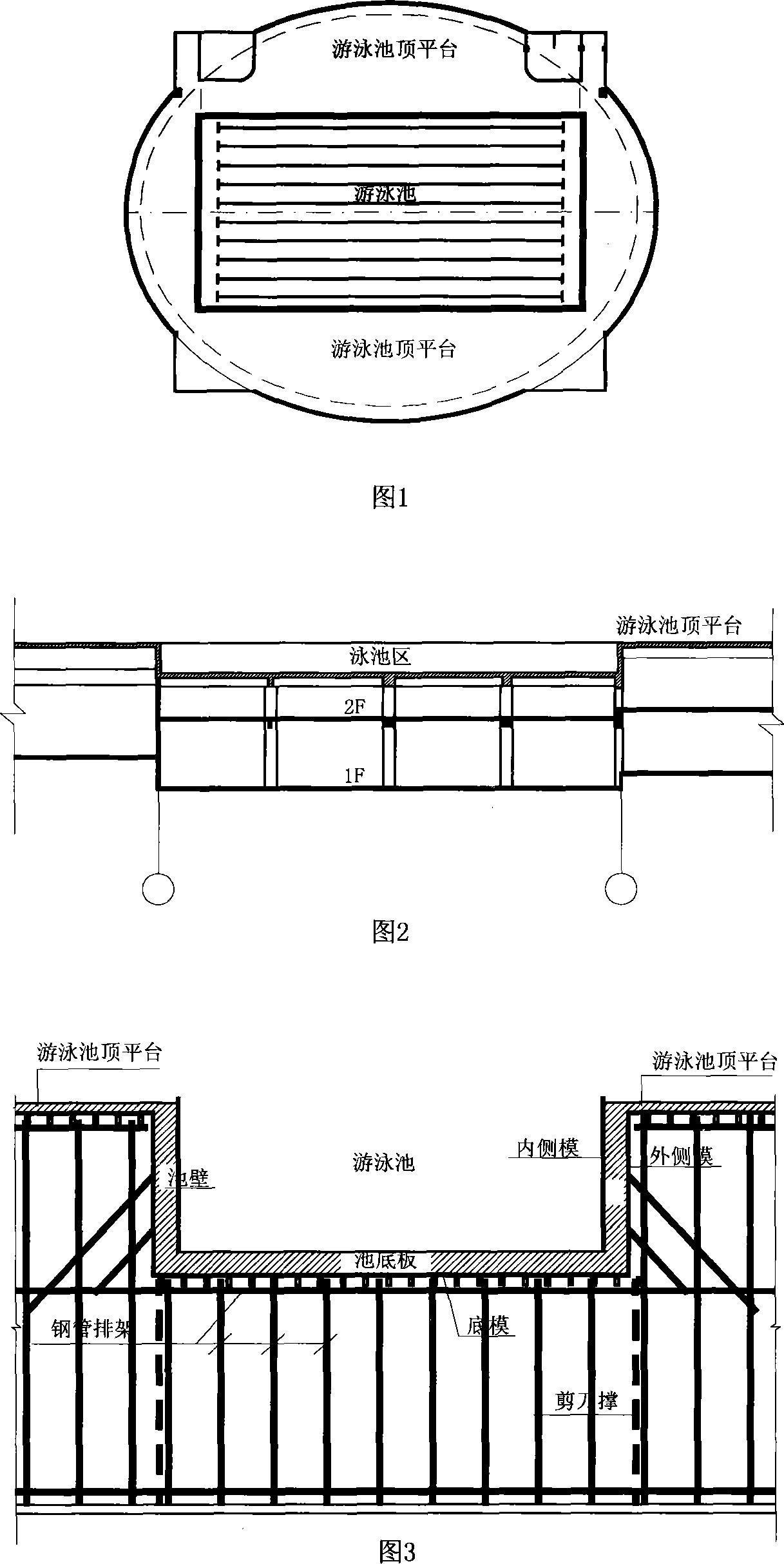

[0019] A preferred embodiment of the present invention takes an open-air overhead swimming pool as an example, which is described in detail as follows: see Fig. 1 , Fig. 2 and Fig. 3 .

[0020] 1. Swimming pool overview: The open-air overhead swimming pool is located on the top of the three-story frame structure of the swimming pool. The net size of the pool is: 50m long, 25m wide, and 1.2-2.0m deep. The pool wall is composed of frame columns and inter-column walls with a thickness of 300mm. The bottom of the pool is a steel concrete cast-in-place slab with a thickness of 300mm.

[0021] There is a large platform around the entrance of the swimming pool, with an elevation of 8.20m, a length of 69.34m from north to south, and a width of 55.54m from east to west. It has a frame beam-slab structure with a thickness of 120mm. The concrete of the swimming pool and platform is C30, and the impermeability is S8.

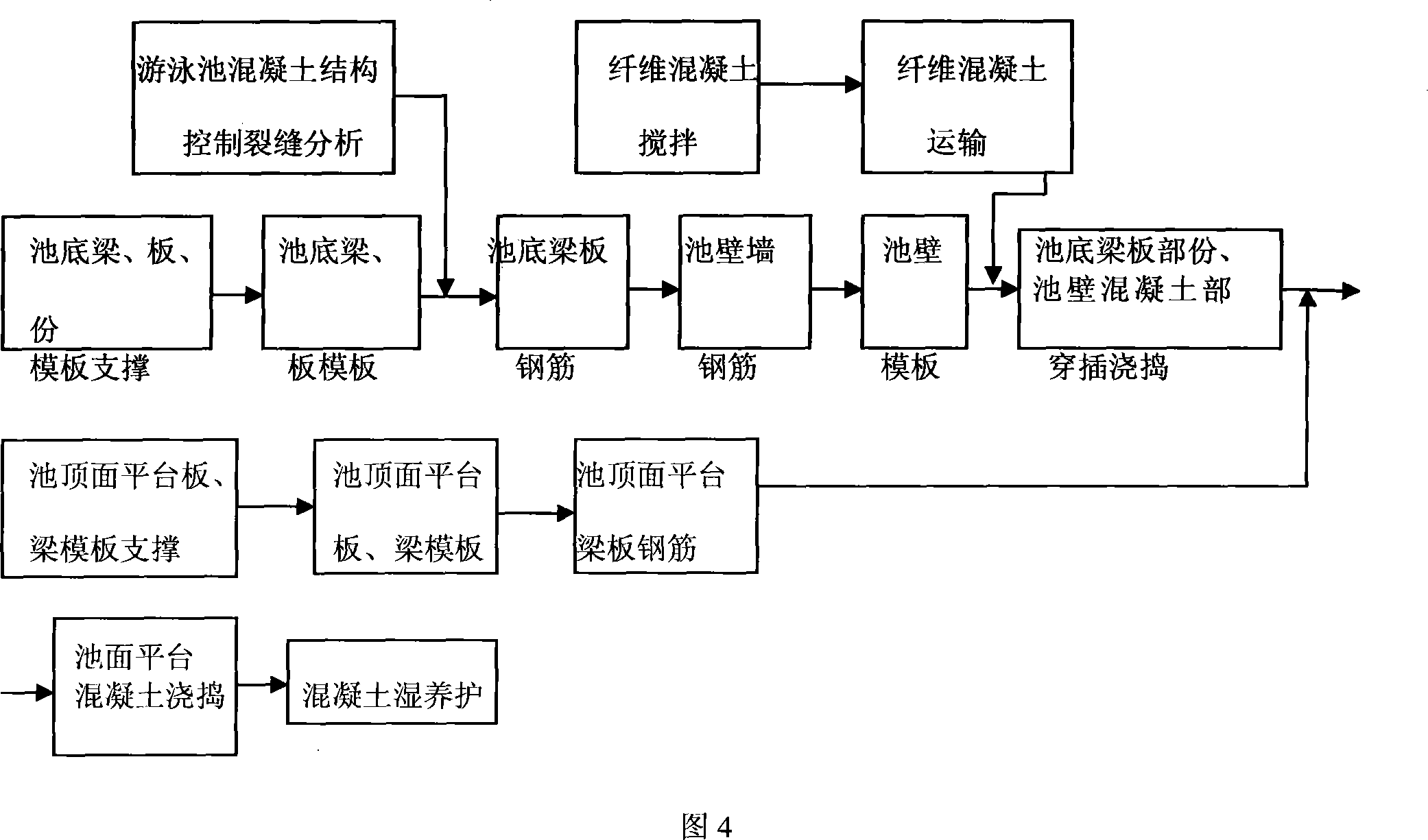

[0022] 2. Construction process of reinforced fiber reinforced concre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com