Amorphous, high-efficiency, high carbon deposition resistance, deep desulfurization catalyst

A desulfurization catalyst and deep desulfurization technology, which is applied in the field of amorphous, high-efficiency, high anti-coking, and deep desulfurization catalysts, can solve problems such as inability to meet requirements, and achieve low production costs, extended service life, and good selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

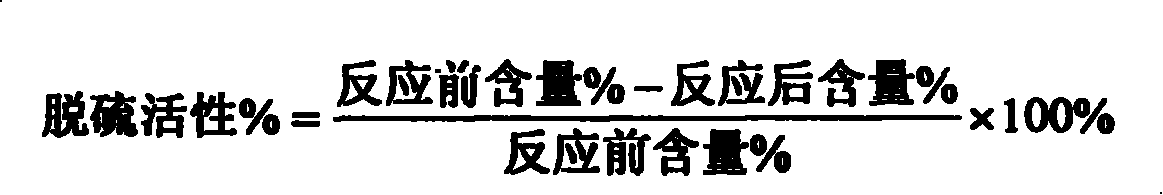

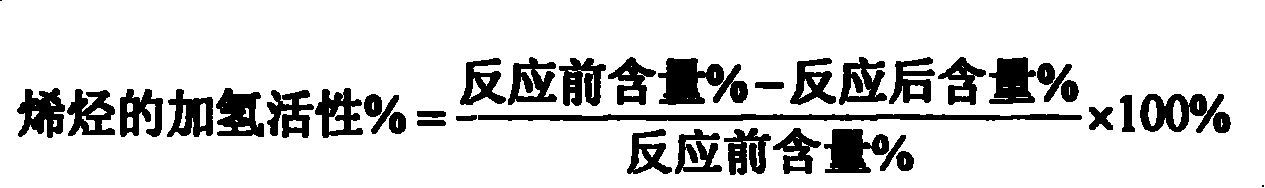

[0029] 5 g of γ-Al modified with 10 wt% titanium 2 o 3 Degas and dehydrate at 110°C for 3 hours, then transfer to a vacuum device, maintain the vacuum at 650mmHg-750mmHg for 2 hours; weigh a certain amount of ammonium molybdate in the solvent and add it to the surface Activator nonylphenol polyoxyethylene ether, and keep stirring until all the ammonium molybdate is dissolved, the amount of solvent is based on covering all the carrier; the solution is impregnated on the carrier that has been vacuum dehydrated and degassed and heated at room temperature Dry under the conditions; put the above dried catalyst into a muffle furnace for calcination, and heat it up to 500°C at a constant heating rate and keep it for 2 hours; repeat the above process to impregnate another active component, cobalt nitrate; A good catalyst is characterized in a self-made microreactor. The evaluation conditions have been given in detail above. The specific characterization results are shown in the follo...

example 2

[0033] The specific preparation process of the catalyst is the same as Example 1, except that the amount of titanium used for carrier modification is 5 wt%. The specific characterization results are shown in the table below:

[0034] composition

[0035] It can be seen that the conversion rate of thiophene is 95.89%, the conversion rate of styrene is 36.44%, and the conversion rate of cyclopentadiene is 32.91%.

example 3

[0037] The specific preparation process of the catalyst is the same as Example 1, except that the surfactant sodium dodecylbenzenesulfonate is added. The specific characterization results are shown in the table below:

[0038] composition

[0039] It can be seen that the conversion rate of thiophene is 97.53%, the conversion rate of styrene is 17.89%, and the conversion rate of cyclopentadiene is 18.36%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com