Micro-pore silicon carbide fiber and preparing method thereof

A technology of microporous silicon carbide and fiber, which is applied in the direction of spinning solution preparation, fiber chemical characteristics, melt spinning method, etc., can solve the problems of difficult to obtain practical application value, low specific surface area, low specific surface area of fiber, etc., and achieve a wide range of practical applications. Application value, effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

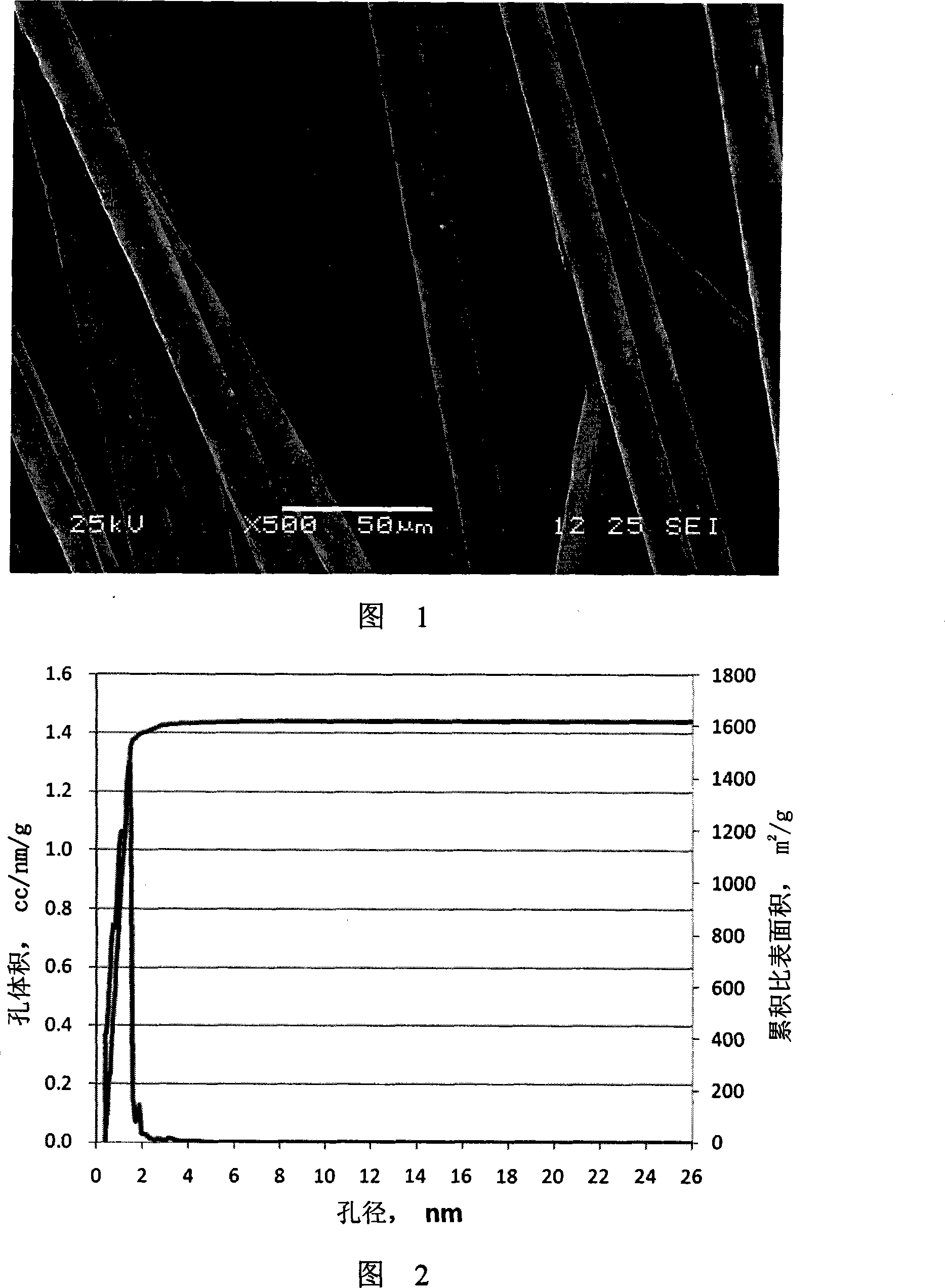

[0025] The Si content of the microporous silicon carbide fiber in this embodiment is 55wt%, the C content is 31wt%, and the O content is 14wt%. It is in the form of continuous fibers. The microscopic morphology is shown in Figure 1, and the fiber pore size distribution is shown in Figure 2. , The volume of the micropores (pore size≤2nm, the same below) accounts for 95vol% of the total pore volume, the specific surface area is 2085m2 / g, and the average pore size is 1.72nm.

[0026] Preparation: Take 10g of PCS and 16g of phenolic with a softening point of 180-190℃ to dissolve in tetrahydrofuran, stir and mix uniformly, distill off the solvent under the protection of high-purity nitrogen with a purity of ≥99%, and place the blend precursor in In the melt spinning device, under the protection of high-purity nitrogen with a purity of ≥99%, it is heated to 330°C and defoamed, and then melt-spinning is performed at 280°C, 0.5MPa and 100m / min at a speed of 100m / min to obtain raw yarn ; P...

Embodiment 2

[0028] The Si content of the microporous silicon carbide fiber in this embodiment is 63wt%, the C content is 24wt%, and the O content is 13wt%. It is in the form of continuous fibers. The micropore volume accounts for 88vol% of the total pore volume, and the specific surface area is 1200m. 2 / g, the average pore diameter is 1.25nm.

[0029] Preparation: The only difference from Example 1 is that the raw materials are blended with 10g PCS and 3g phenolic with a softening point of 180-190°C.

Embodiment 3

[0031] The Si content of the microporous silicon carbide fiber of this embodiment is 48wt%, the C content is 38wt%, and the O content is 14wt%. It is in the form of continuous fibers. The micropore volume accounts for 89vol% of the total pore volume, and the specific surface area is 1609m. 2 / g, the average pore size is 1.95nm.

[0032] Preparation: The only difference from Example 1 is that the raw materials are blended with 10 g of PCS and 25 g of phenolic with a softening point of 180-190°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com