Bacillus licheniformis and application thereof

A technology of Bacillus licheniformis, bl57cgmccno.2277, applied in the direction of bacteria, enzymes, biochemical equipment and methods, etc., can solve the problems of limited usage, unsatisfactory effect, and corresponding synchronous reduction of feeding costs, and achieve high value , Improve the effect of using value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

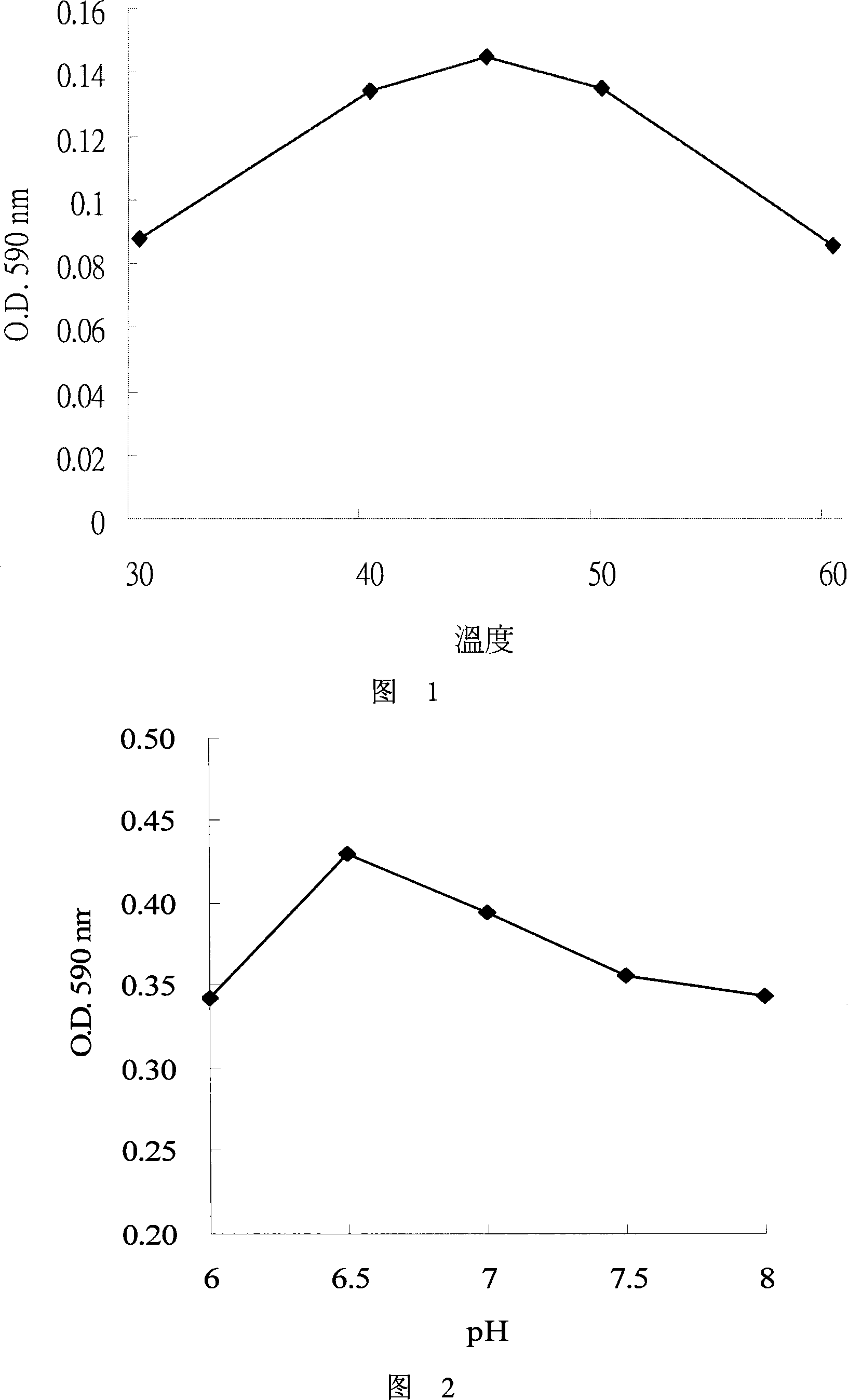

[0023] Example 1, the acquisition of Bacillus licheniformis (Bacillus licheniformis) BL57 CGMCC No. 2277 and its culture condition detection

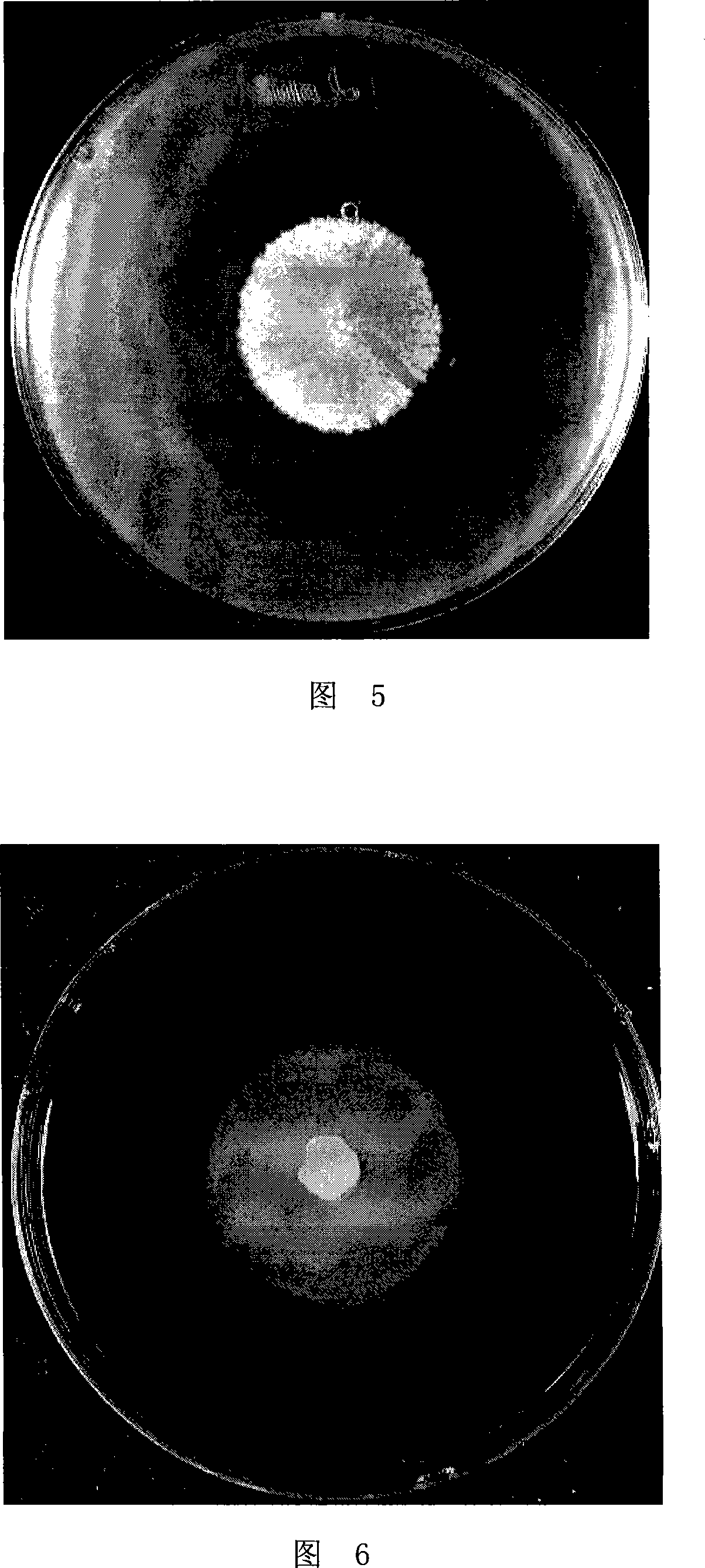

[0024] 1. Screening and identification of Bacillus licheniformis BL57 CGMCC №.2277

[0025] 1) Acquisition of Bacillus licheniformis BL57 CGMCC №.2277

[0026] One gram of soil was taken from three different locations of soil samples in Taichung County, Taiwan Province, and 10ml Trypticase was added to each TM Soy Broth (TSB culture fluid) (each liter contains 20.0g of tryptone (Tryptose), 1.0g of glucose (Dextrose), 2.0g of disodium phosphate (Disodium Phosphate), 1.0g of potassium nitrate (PotassiumNitrate) , using Mandels-Reese medium (per liter containing 1.0 g of peptone (Peptone), 10.0 g of carboxymethyl cellulose (CMC, Carboxymethyl cellulose), (NH 4 ) 2 SO 4 1.4g, Urea0.3g, K 2 HPO 4 2.0g, CaCl 2 .H 2 O0.4g, MgSO 4 .7H 2 O0.3g, FeSO 4 .7H 2 O5.0mg, MnSO 4 .H 2 O1.6mg, ZnSO 4 .7H 2 O1.4mg, CoCl 2 .7H 2 (2.0mg, ...

Embodiment 2

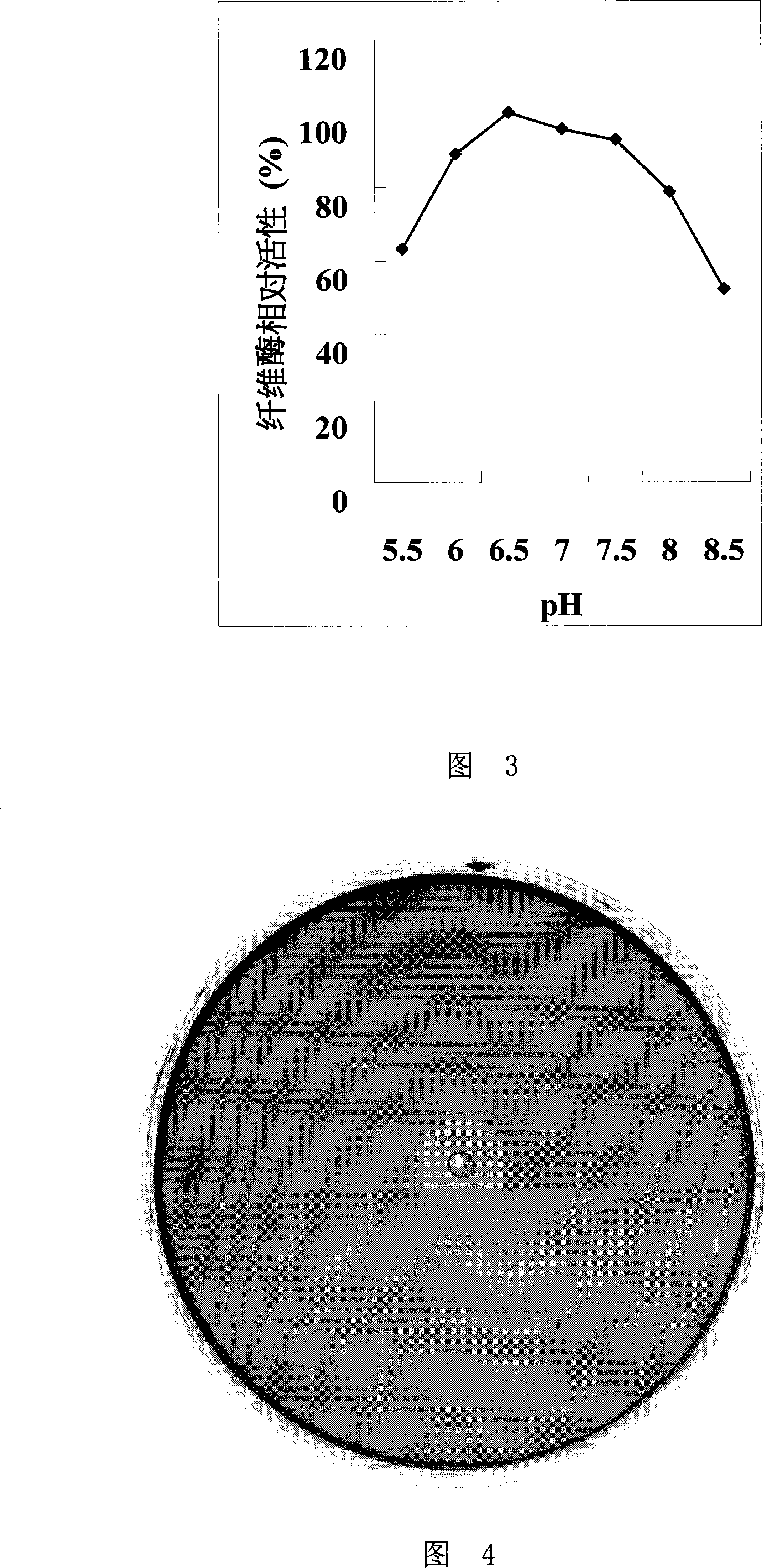

[0044] Example 2, Detection of Enzyme Activity Produced by Bacillus licheniformis BL57 CGMCC No. 2277

[0045] 1. Identification of carboxymethyl cellulase activity of Bacillus licheniformis BL57 CGMCC №.2277, and confirmation of the optimal pH value of the enzyme

[0046] 1) Preparation of enzyme solution samples produced by Bacillus licheniformis BL57 CGMCC №.2277

[0047] Bacillus licheniformis (Bacillus licheniformis) BL57 CGMCC №.2277 according to 10 9 The inoculation amount of cfu / L was inoculated in Mendels-Reese culture medium, and after culturing at 45°C for 24 hours, the cultured Bacillus licheniformis (Bacillus licheniformis) BL57 CGMCC №.2277 fermentation broth was centrifuged at 12,000rpm at 4°C for 10 minutes Afterwards, the supernatant was filtered with a filter membrane with a filter diameter of 0.45 μm to obtain an enzyme liquid (fermentation liquid supernatant), which was stored at -20°C.

[0048] 2) Carboxymethyl cellulase identification of the enzyme solu...

Embodiment 3

[0062] Embodiment 3, the application of Bacillus licheniformis (Bacillus licheniformis) BL57 CGMCC No. 2277 in the production of feed utilizing raw materials containing plant fiber

[0063] In this example, Bacillus licheniformis (Bacillus licheniformis) BL57 CGMCC No. 2277 is used to ferment sunflower disc powder, wheat stalk, mung bean stalk powder, millet stalk powder, sunflower stalk powder, corncob powder, corn stalk or distiller's grains as raw materials. Production feed, the specific method is as follows:

[0064] Use a 500ml beaker to fill the raw materials, weigh 10g of sunflower powder, wheat stalk, mung bean stalk powder, millet stalk powder, sunflower stalk powder, corncob powder, corn stalk or distiller's grains as raw materials, and add 10g to each beaker respectively. 6 cfu / g raw material Bacillus licheniformis (Bacillus licheniformis) BL57 CGMCC №.2277, and add 50ml of deionized water, after mixing evenly, adjust the pH value to 6.5, put it in a 45°C incubator,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com