FPGA based automatic safe monitoring system for tower crane

A safety monitoring system and tower crane technology, applied in general control systems, control/regulation systems, computer control, etc., can solve the problems of maintenance and use restrictions, expensive industrial computers, and cost control disadvantages, so as to improve safety and reduce use. The effect of security incidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in further detail below in conjunction with accompanying drawing:

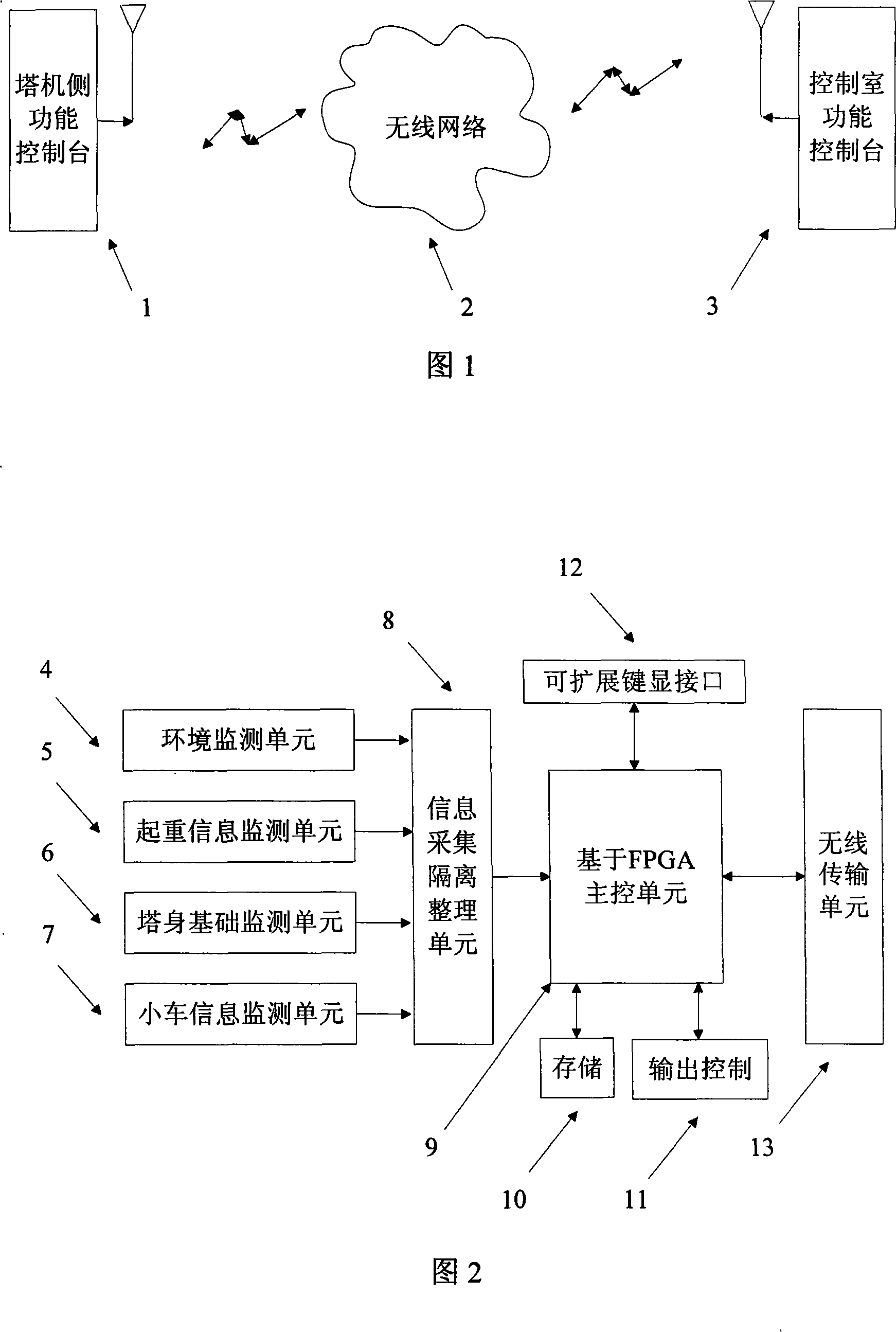

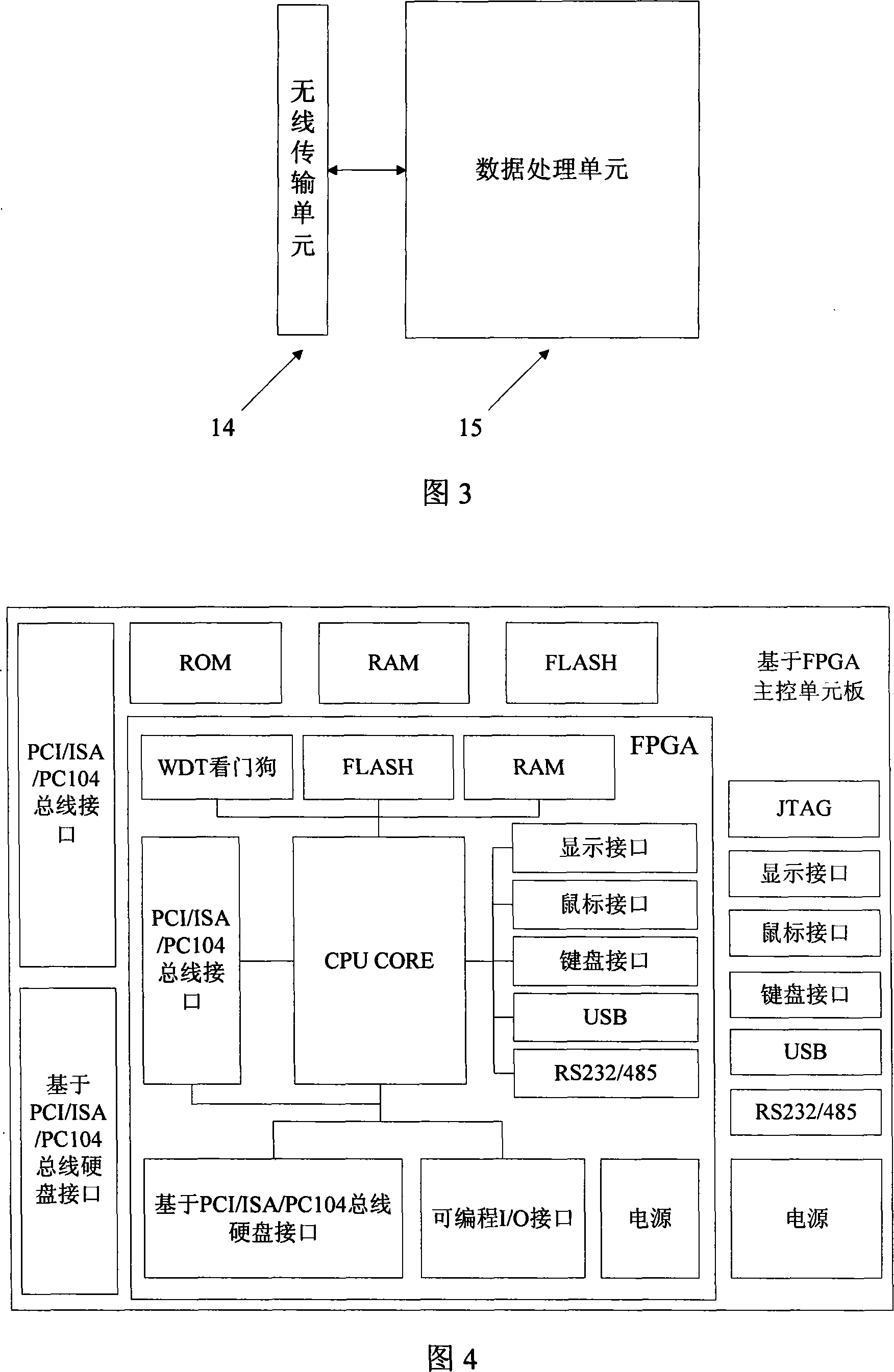

[0014] As shown in Figures 1 to 4, the FPGA-based automatic safety monitoring system for tower cranes includes a functional console 1 on the side of the tower crane and a functional console 3 on the side of the control room. 1 to collect, analyze, store, and transmit to the functional console 3 at the control room side through the wireless network 2, for data backup and storage, and various subsequent processing.

[0015] The tower crane side function console 1 consists of an environment monitoring unit 4, a lifting information monitoring unit 5, a tower body foundation monitoring unit 6, a trolley information monitoring unit 7, an information collection and isolation unit 8, an FPGA-based main control unit 9, and a storage unit 10. Composed of an output control unit 11 , an expandable key display unit 12 and a wireless transmission unit 13 . FPGA-based main control u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com