Optical fiber grating sonic device

A fiber grating and hydrophone technology, applied to transducers and instruments used underwater, using optical devices to transmit sensing components, etc., can solve the problems of difficult measurement of high pressure and complicated process, and achieve sound pressure sensitivity. , Small size, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

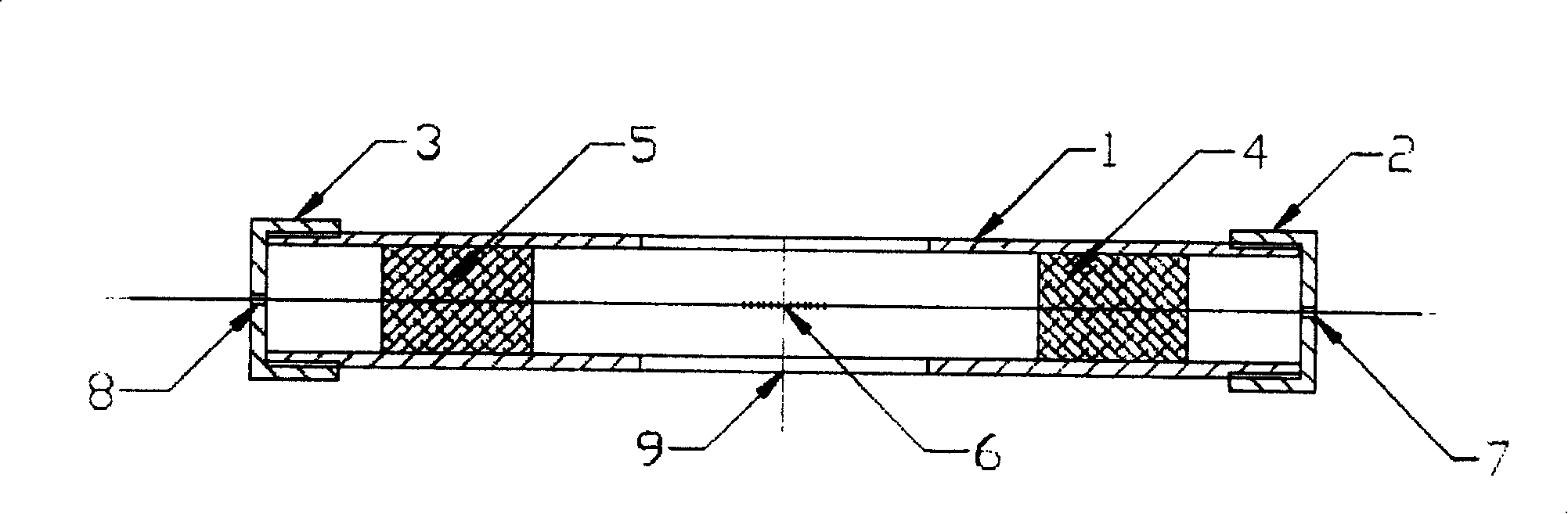

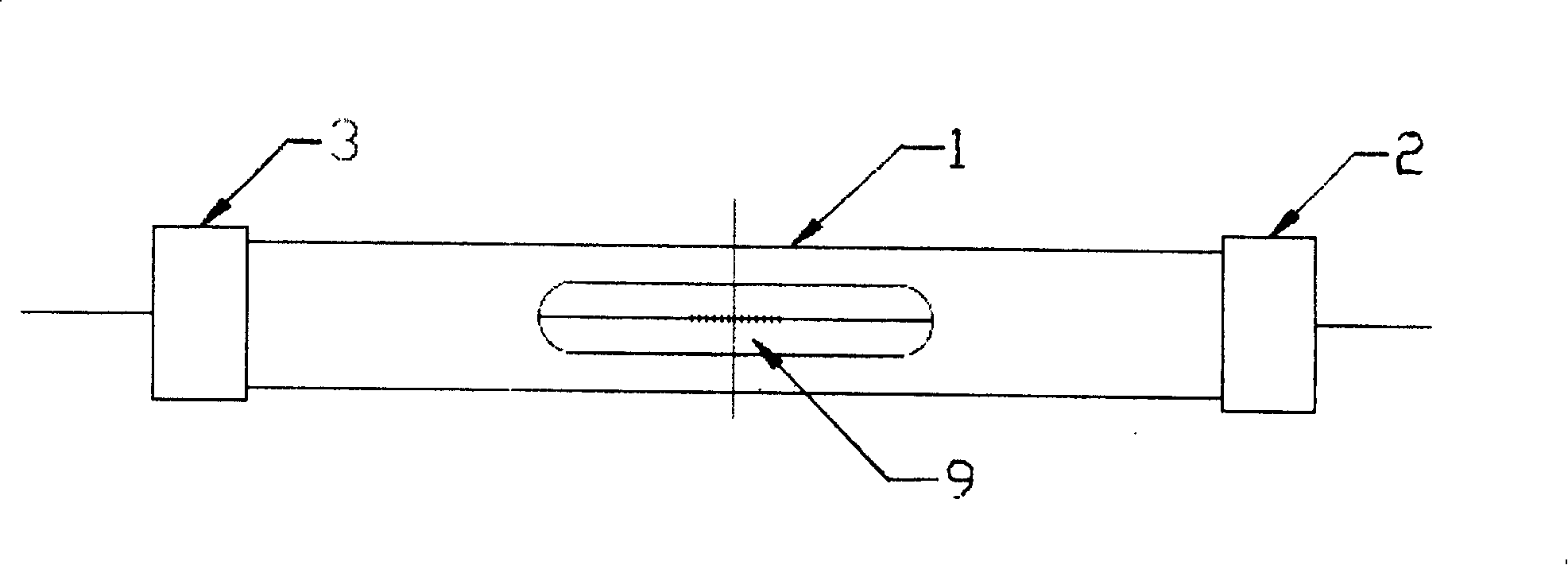

[0030] Such as figure 1 as shown, figure 1 Structural sectional view of the fiber grating hydrophone provided by the present invention. The fiber grating hydrophone includes: a support cylinder 1, the support cylinder 1 is the main body of the fiber grating hydrophone, and the support cylinder 1 is cylindrical. A first end cap 2 and a second end cap 3, the first end cap 2 and the second end cap 3 are respectively installed at both ends of the support cylinder 1 for sealing; the first end cap 2 and the second end cap There are small holes 7 and 8 in the center of 3, which are used to lead out the pigtail of the optical fiber 6; a first elastic body 4 and a second elastic body 5, the first elastic body 4 and the second elastic body 5 are located in the support cylinder 1 The two sides close to the end are used to feel the sound pressure and generate deformation. The material of the first elastic body 4 and the second elastic body 5 is silicon rubber or polyurethane rubber. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com