Tensile adjustable connection mechanism for orbit beam

A technology for connecting mechanisms and rail beams, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of insufficient self-weight, difficult adjustment, and insufficient practicability, and achieves simple structure, low cost, and continuous vertical height. Infinitely adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

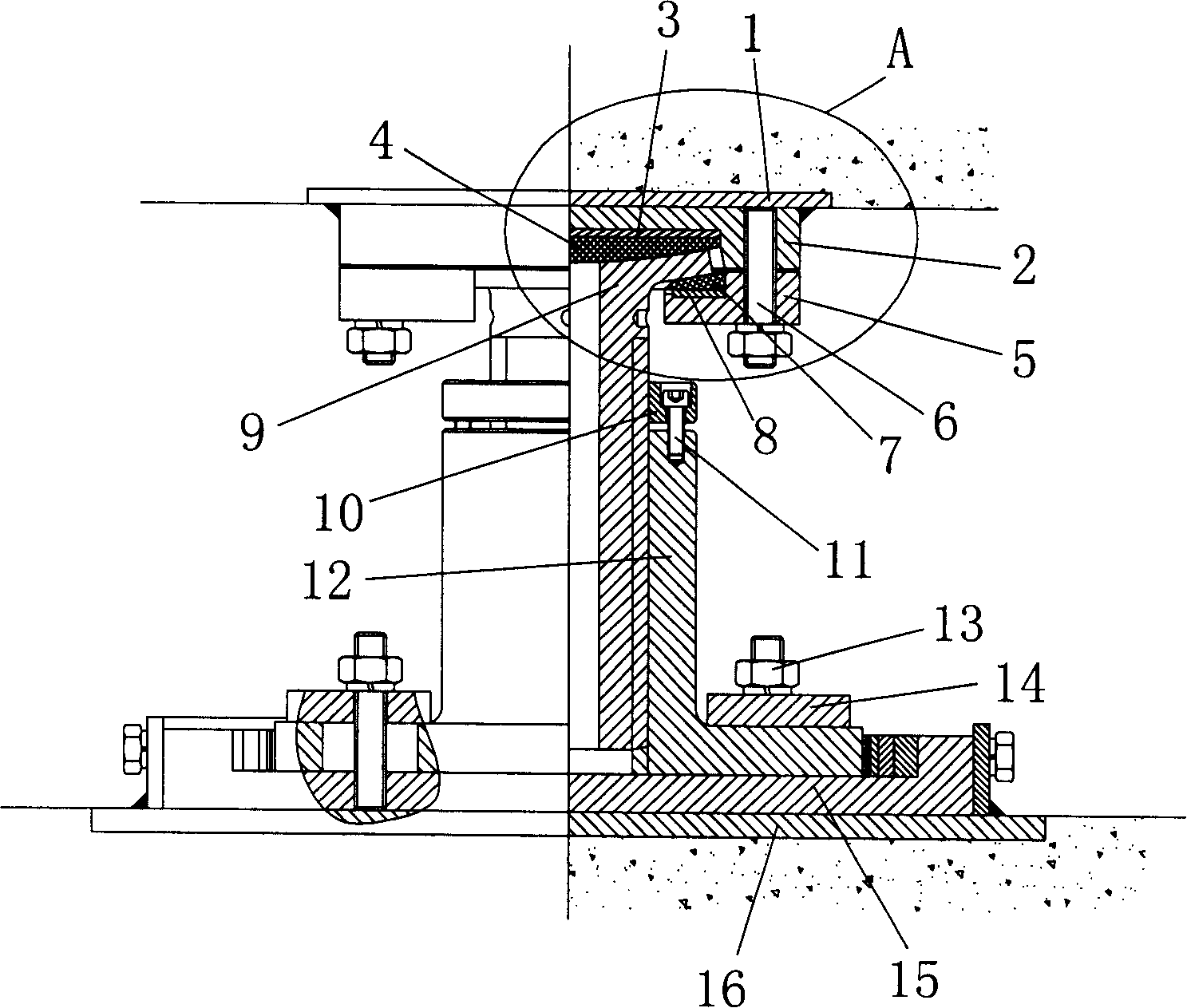

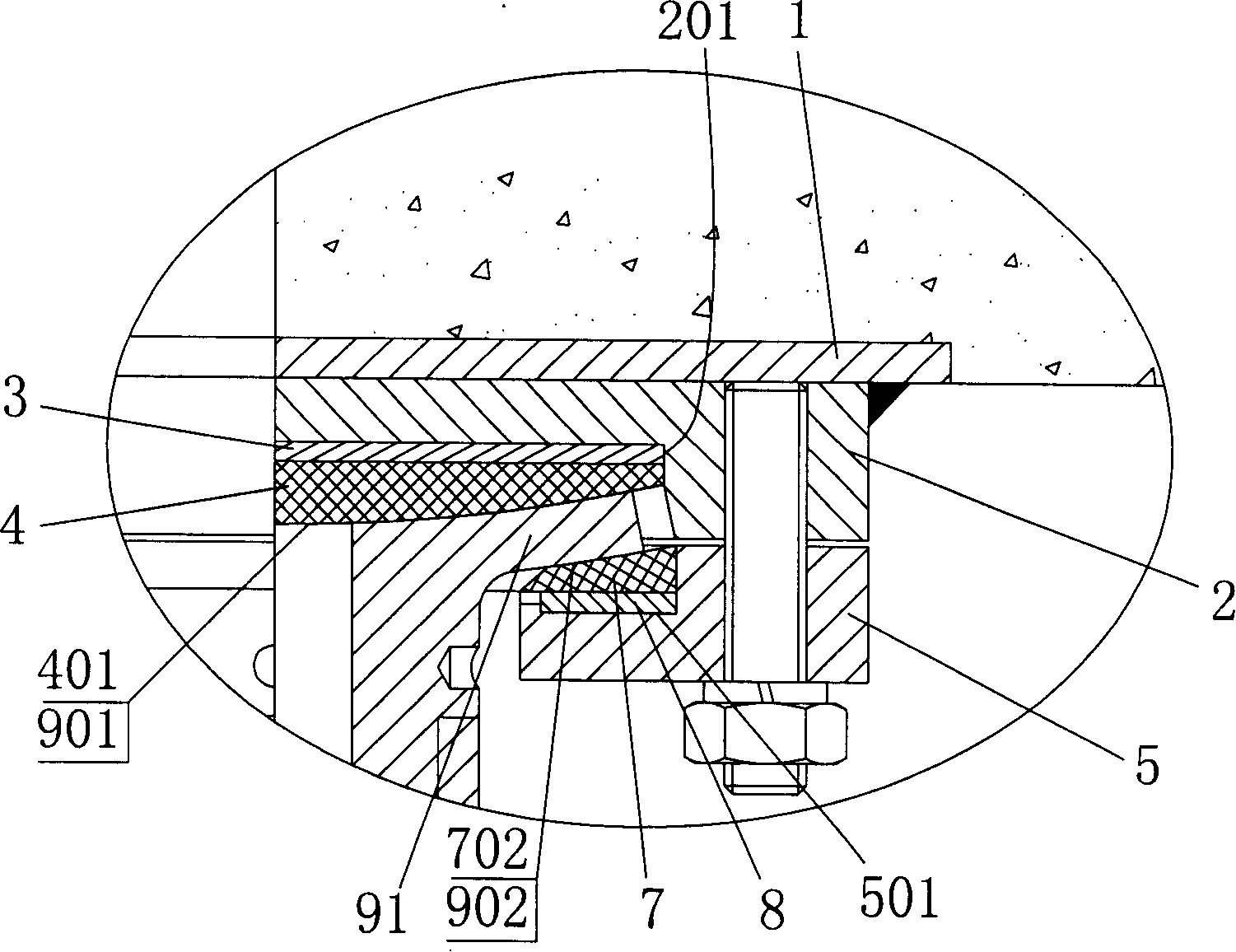

[0019] Such as figure 1 with figure 2 As shown, the upper embedded plate 1 and the lower embedded plate 16 of the track beam of the present invention are rigidly fixed on the bottom of the track beam (not shown) and the top of the pier (not shown) by pre-embedding, etc. ); the top plate 2 and the upper embedded plate 1 are fixedly connected by welding. In this embodiment, the bottom of the top plate 2 is provided with a concave cavity 201, and the first upper sliding plate 3 and the first lower sliding plate 4 are accommodated in the concave cavity. In the cavity 201; one end of the T-shaped screw rod 9 is provided with a flange 91, and its vertical cross-section becomes T-shaped, and the end face 901 of the end with the flange 91 is a concave surface, preferably a concave spherical surface, the first The lower sliding plate 4 is placed on the T-shaped screw rod 9 through its convex bottom surface 401 and the concave surface 901 of the T-shaped screw rod 9 in a relatively ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com