Method and agent for chemical conversion treatment and chemically conversion-treated members

A chemical conversion treatment and chemical conversion technology, which is applied in the field of chemical conversion treatment, can solve the problems such as the surface treatment of high-strength steel plates that have not been studied, and achieve the effect of sufficient substrate coverage and sufficient coating film adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Prepare commercially available cold-rolled steel sheets (SPCC-SD, manufactured by Nippon Testpanel, 70mm×150mm×0.8mm), galvanized steel sheets (GA, manufactured by Nippon Testpanel, 70mm×150mm×0.8mm), 6K21 aluminum sheets for automobiles (AL , manufactured by Kobe Steel Corporation, 70mm×150mm×0.8mm), high-strength steel plate (JSC590R, manufactured by Nippon Steel Corporation, 70mm×150mm×0.8mm), high-strength steel plate (JSC780T, manufactured by Nippon Steel Corporation, 70mm × 150mm × 0.8mm) and high-strength steel plate (JSC1180Y, manufactured by Nippon Steel Corporation, 70mm × 150mm × 2.3mm), as the metal structure.

[0090] [Pretreatment of metal structures before chemical conversion treatment]

[0091] [skim treatment]

[0092] Specifically, the metal structure was immersed in an aqueous solution containing 1.5% by mass of "Agent" and 0.9% by mass of "Agent" as an alkaline degreasing treatment agent "Surf Cleaner SD250 (trade name)" (manufactured by Nippon Pain...

Embodiment 2

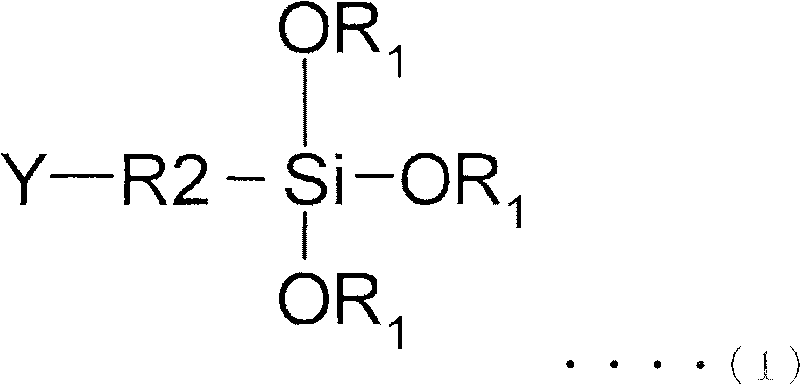

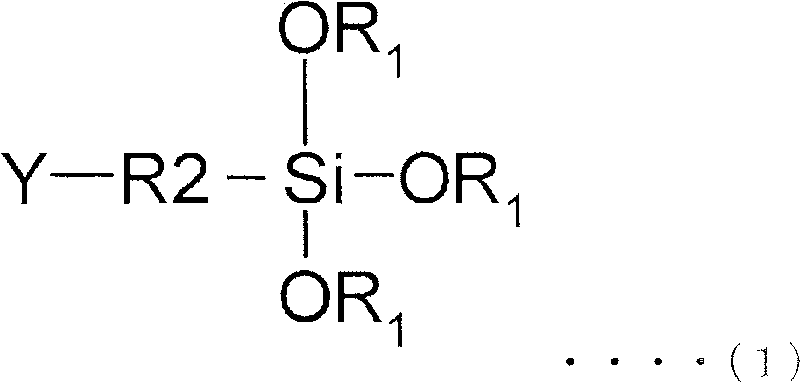

[0106] Instead of the bis(2-hydroxyethyl)- A test panel was obtained in the same procedure as in Example 1 except that 3-aminopropyltriethoxysilane was used as the hydroxyl group-containing alkoxysilane. Table 1 shows the measurement results of the obtained test panels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com