Cellulose acylate film, process for producing the same, polarizing plate, retardation film, optical compensating film, antireflection film, and liquid-crystal display

A technology of cellulose acylate and a manufacturing method, applied in optics, polarizing elements, optical elements, etc., can solve the problems of decreased optical properties of films, decreased dimensional stability, uneven color, etc., and achieves excellent dimensional stability, excellent performance, Suppresses the effect of uneven color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment -A

[0693] 1. Cellulose acylate resin

[0694] (1-1) Synthesis of cellulose acetate propionate (CAP)

[0695] 150 parts by mass of cellulose (hardwood pulp) and 75 parts by mass of acetic acid were placed in a reaction container equipped with a reflux device, and vigorously stirred for 2 hours while heating to 60°C. The pretreated cellulose is swollen and pulverized into fluff. The reaction vessel was cooled in an ice-water bath at 2°C for 30 minutes.

[0696] Separately, a mixture of 1,545 parts by mass of propionic anhydride and 10.5 parts by mass of sulfuric acid was prepared as an acylating agent, cooled to -30° C., and added at once to the reaction vessel containing the pretreated cellulose. After 30 minutes had elapsed, the temperature of the external equipment was gradually increased, and the internal temperature was adjusted so that the internal temperature reached 25° C. after 2 hours from the addition of the acylating agent. Cool the reaction vessel with an ice-water ...

Embodiment 1

[0752] 5. Fabrication of Polarizer

[0753] (5-1) Surface treatment

[0754] The stretched cellulose acylate film was saponified according to the dipping method described below. No matter which saponification method is used to manufacture, the polarizing plate exhibits the same excellent optical performance.

[0755] (5-1-1) Dipping saponification

[0756] The cellulose acylate film was dipped for 2 minutes in a saponified solution in which a 1.5 mol / L NaOH aqueous solution was tempered to 60°C. Then, after immersing in a 0.05 mol / L sulfuric acid aqueous solution for 30 seconds, it passed through a water bath.

[0757] (5-1-2) Coating Saponification

[0758] 20 parts by weight of water was added to 80 parts by weight of isopropanol to dissolve KOH thereinto 1.5 mol / L, and the solution adjusted to 60° C. was used as a saponification solution. The saponification liquid is 10g / m 2 It was applied on a cellulose acylate film at 60° C. and saponified for 1 minute. Then, use a...

Embodiment -B

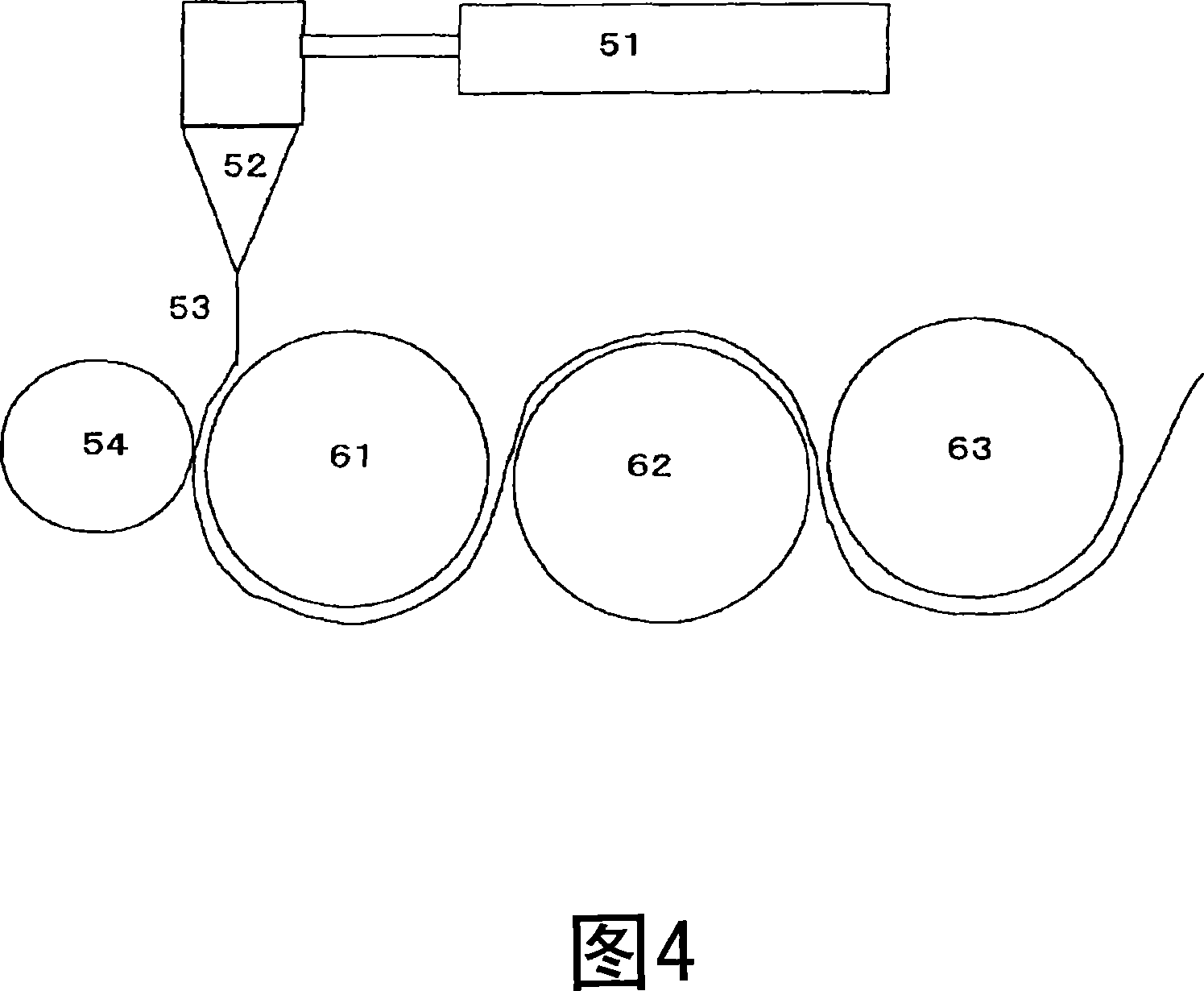

[0778]Using cellulose acylate raw materials having the same composition as in Examples 30 and 31 in Table 1 of Example-A, they were dried at 100°C for 5 hours using dehumidified air with a dew point temperature of -40°C, so that the moisture content was 0.01% by mass. the following. This was charged into a hopper at 80° C., and melted in a melt extruder adjusted from 180° C. (inlet temperature) to 230° C. (outlet temperature). In addition, the diameter of the screw used here was 60 mm, L / D=50, and the compression ratio was 4. The resin extruded from the melt extruder was metered and delivered at a constant amount by a gear pump, but at this time, the rotational speed of the extruder was changed so that the resin pressure before the gear pump could be controlled at a constant pressure of 10 MPa. The molten resin sent out by the gear pump is filtered with a blade-shaped disc filter with a filtration accuracy of 5 μmm. After passing through the static mixer, it is passed through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com