Nozzle for minisize gas-turbine combustor

A micro gas turbine and combustor technology, applied in the direction of combustors, continuous combustion chambers, burners, etc., can solve problems such as no cooling technology, large changes, hidden dangers of unit safety and stability, and reduce maintenance and operation costs. The effect of strengthening the mutual shearing action and prolonging the interval between overhauls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

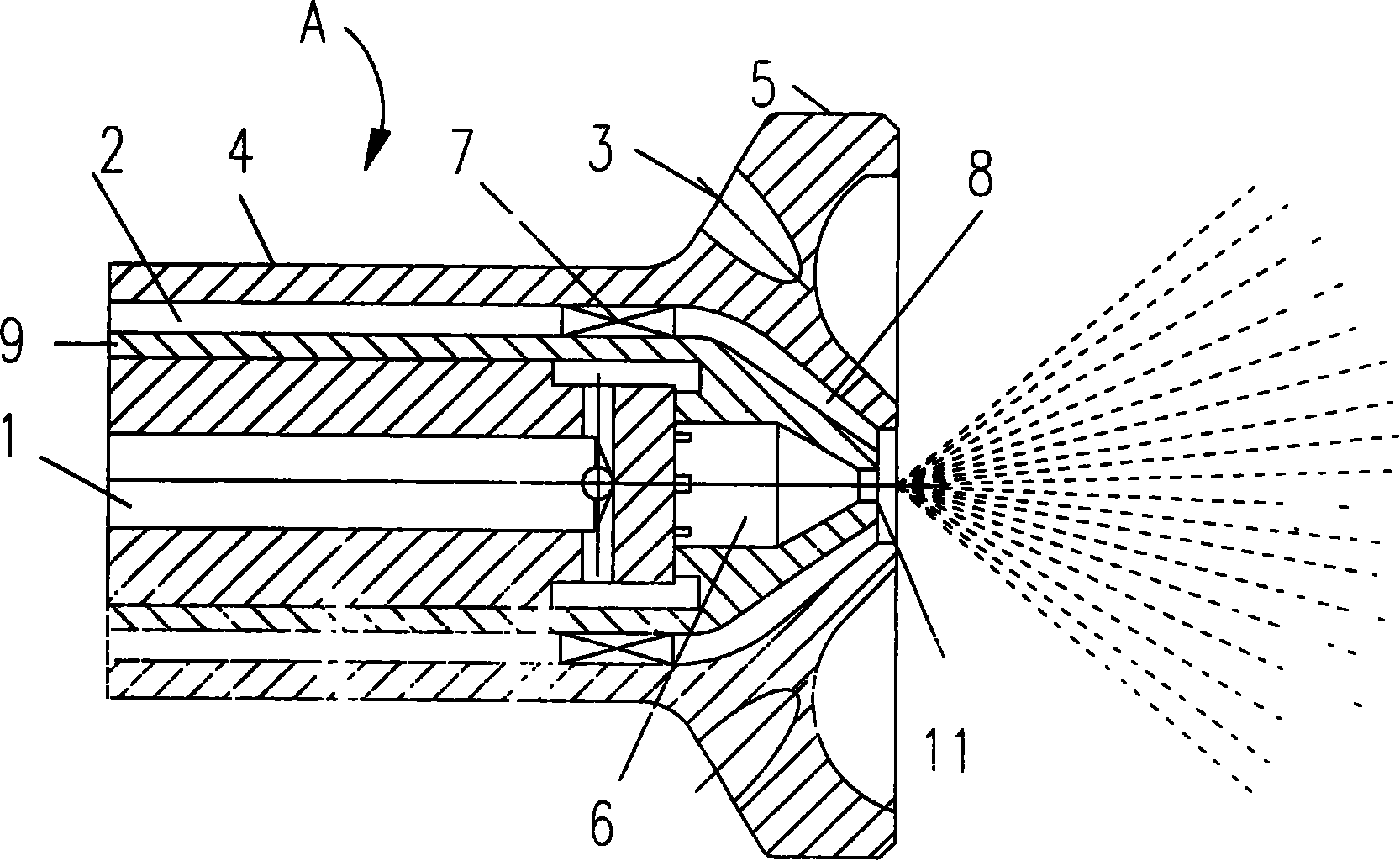

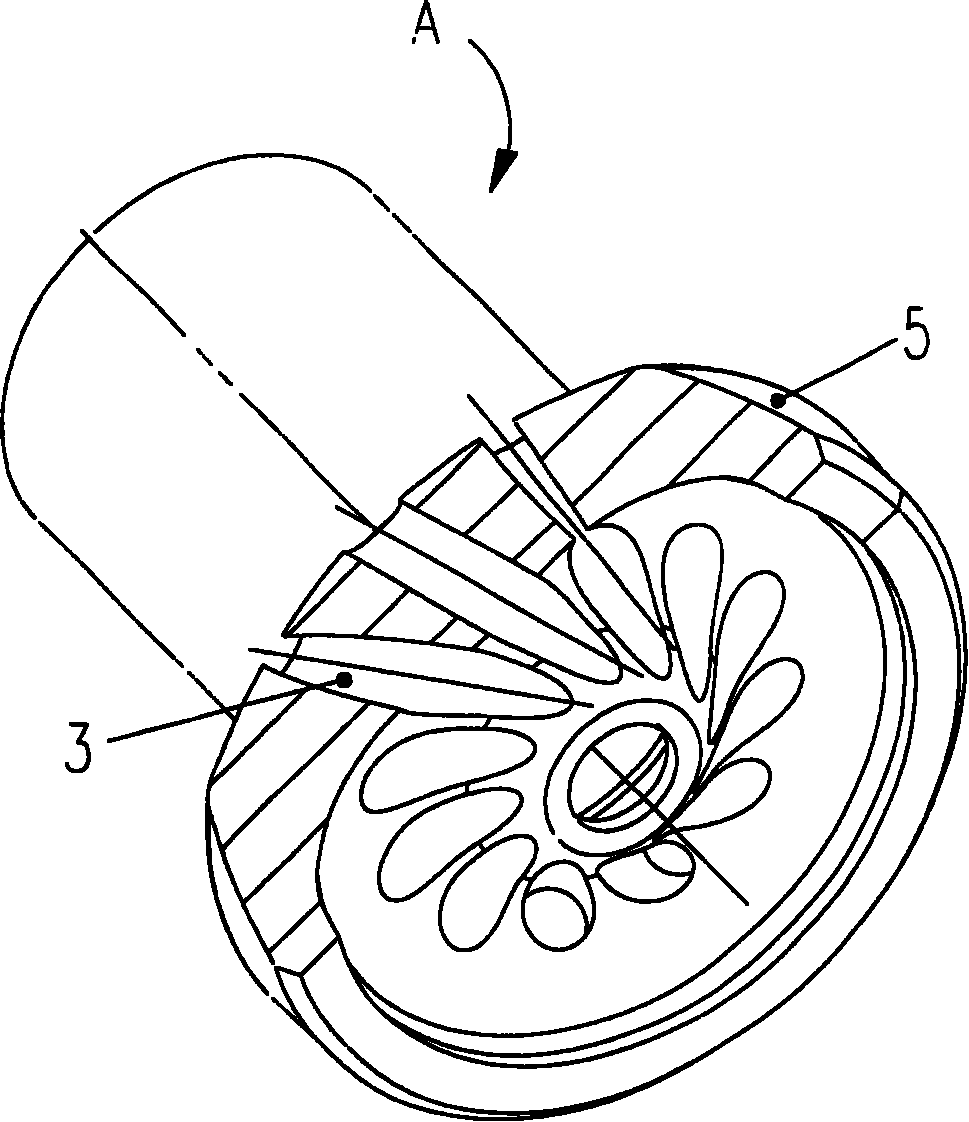

[0030] Figure 1 to Figure 4 It is a specific embodiment of the present invention.

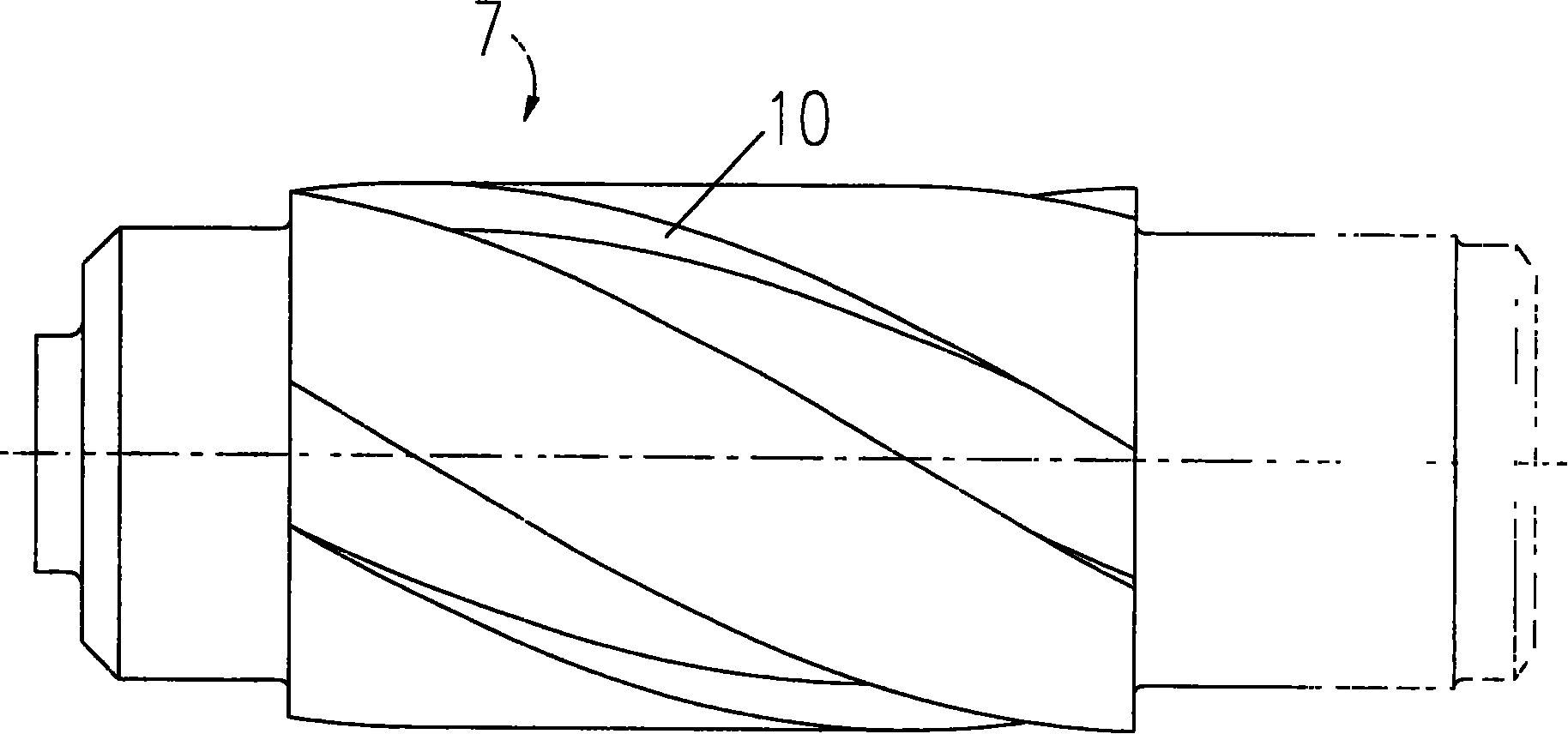

[0031] refer to figure 1 As shown, a micro gas turbine combustor nozzle A is a small-sized nozzle for a 100kW class micro gas turbine combustor, which consists of three parts: fuel oil circuit 1, gas circuit 2 and burner root air injection channel 3. The diameter of the outer wall 4 of the nozzle A is not greater than 15 mm, and the diameter of the outer wall 5 of the air injection channel 3 at the root of the burner is not greater than 25 mm. On the premise of not increasing the manufacturing cost of nozzle A and adopting conventional processing methods, the efficient atomization of fuel can be achieved in such a small-scale space through optimized design. Among them, the oil circuit 1 is provided with a built-in centrifugal atomization device 6, the air circuit is provided with an axial swirler 7, and an annular constriction 8 is provided before the atomized air flow is sprayed out. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com