System and method for lubricating a transport device

A lubrication system and lubrication point technology, applied in transportation and packaging, lubricating parts, engine lubrication, etc., can solve problems such as the complex structure of rotary-stroke piston pumps, reduce ecological burden, prevent excessive lubrication, and prevent lubrication Insufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

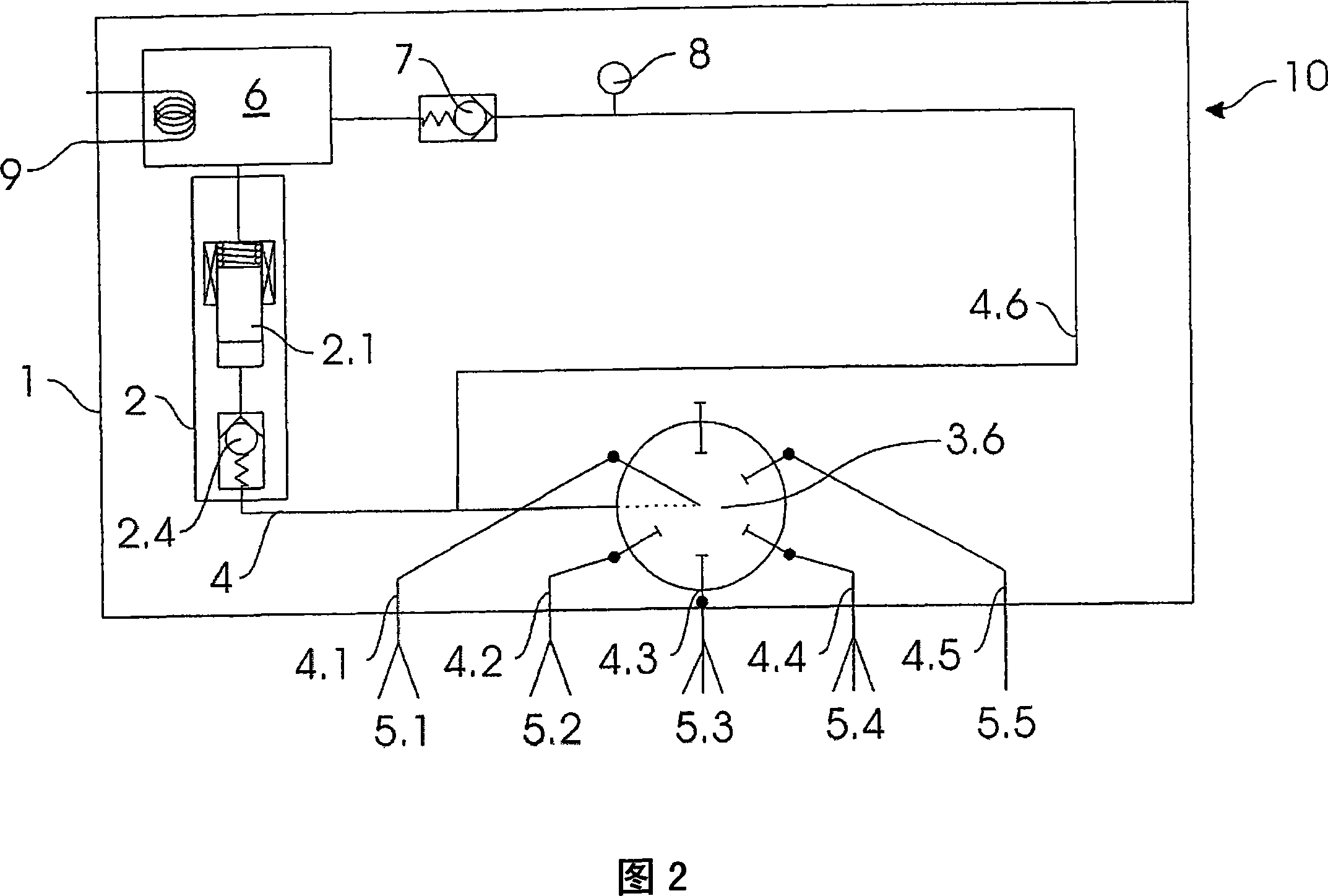

[0042] A lubricating system according to a first embodiment of the present invention is shown in Figure 1; This includes a movable piston 2.1 pushed by an electromagnet to dampen the compression spring force. A spring-loaded check valve 2.4 is arranged opposite the piston 2.1. This piston 2 . 1 presses the lubricant, which in the typical embodiment comprises lubricating or synthetic oil, from the extraction side of the pump 2 to the pressure side. The spring-loaded check valve 2.4 enables precise and exact dosing of lubricant. In addition, backflow of lubricant from the lubricant line 4 is prevented by means of the spring-loaded check valve 2.4. A precise and exact dosing is ensured or ensured by means of the piston stroke against the spring-loaded check valve 2.4. The pressure level is maintained by the spring of the spring-loaded check valve 2.4 and achieves constant lubricant pressure.

[0043] If the electromagnet pushes or moves the piston 2 . 1 forward or to the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com