Dip-roll sleeve and method for manufacturing the same

A manufacturing method and technology of sunken rollers, which are applied in the field of manufacturing of sunken roller bushings, can solve the problems of low strength of powder metallurgy bushings, affecting continuous production of galvanizing lines, poor corrosion resistance of molten zinc, etc. The effect of low production cost and thick layer of corrosion resistance of molten zinc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

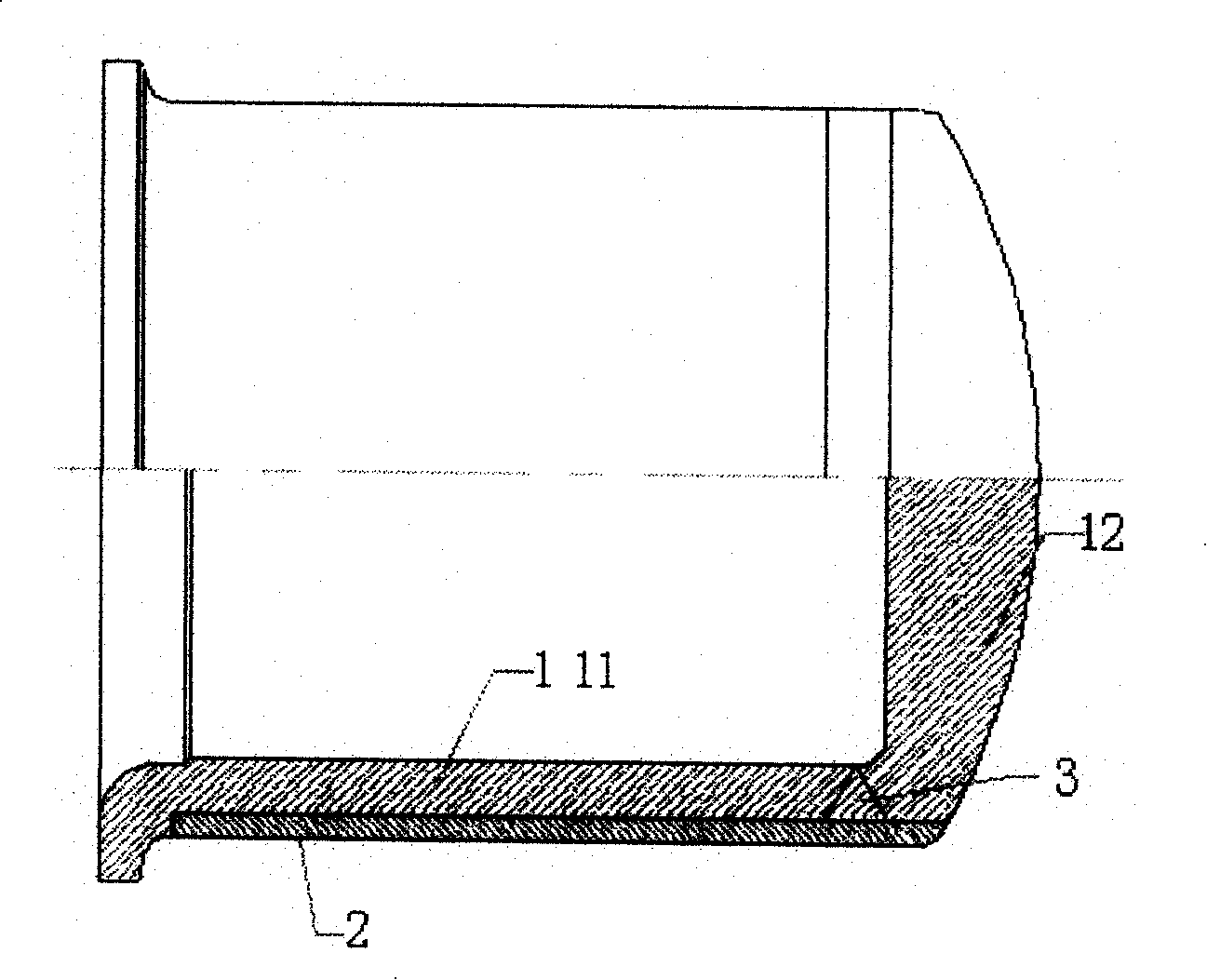

[0015] Shaft structure such as figure 1 As shown: the shaft sleeve is composed of a stainless steel substrate 1 and a cobalt-based laser cladding layer 2. The cobalt-based laser cladding layer 2 covers the stainless steel substrate 1. The stainless steel substrate 1 is welded by an inner sleeve 11 and a plug 12. , 3 is the welding port.

[0016] The process steps are as follows:

[0017] 1. Machining stainless steel inner sleeve 11 with stainless steel pipe and machining plug 12 with stainless steel plate.

[0018] 2. Weld the stainless steel inner sleeve 11 and the plug 12 together.

[0019] 3. Machining, leaving 2~3mm laser cladding allowance.

[0020] 4. Laser cladding, on the outer circle of the stainless steel substrate 1, first use cobalt-based powder with better cladding performance as a primer, and then cladding cobalt-based powder with good wear resistance and molten zinc corrosion resistance to the design size of the shaft sleeve And leave the machine to add a ma...

Embodiment 2

[0023] Shaft structure such as figure 1 As shown: the shaft sleeve is composed of a stainless steel substrate 1 and a cobalt-based laser cladding layer 2. The cobalt-based laser cladding layer 2 covers the stainless steel substrate 1. The stainless steel substrate 1 is welded by an inner sleeve 11 and a plug 12. , 3 is the welding port.

[0024] The process steps are as follows:

[0025] 1. Machining stainless steel inner sleeve 11 with stainless steel pipe and machining plug 12 with stainless steel plate.

[0026] 2. Weld the stainless steel inner sleeve 11 and the plug 12 together.

[0027] 3. Machining, leaving 2~3mm laser cladding allowance.

[0028] 4. Laser cladding, on the outer circle of the stainless steel substrate 1, first use cobalt-based powder with better cladding performance as a primer, and then cladding cobalt-based powder with good wear resistance and molten zinc corrosion resistance to the designed size of the shaft sleeve And leave the machine to add a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com