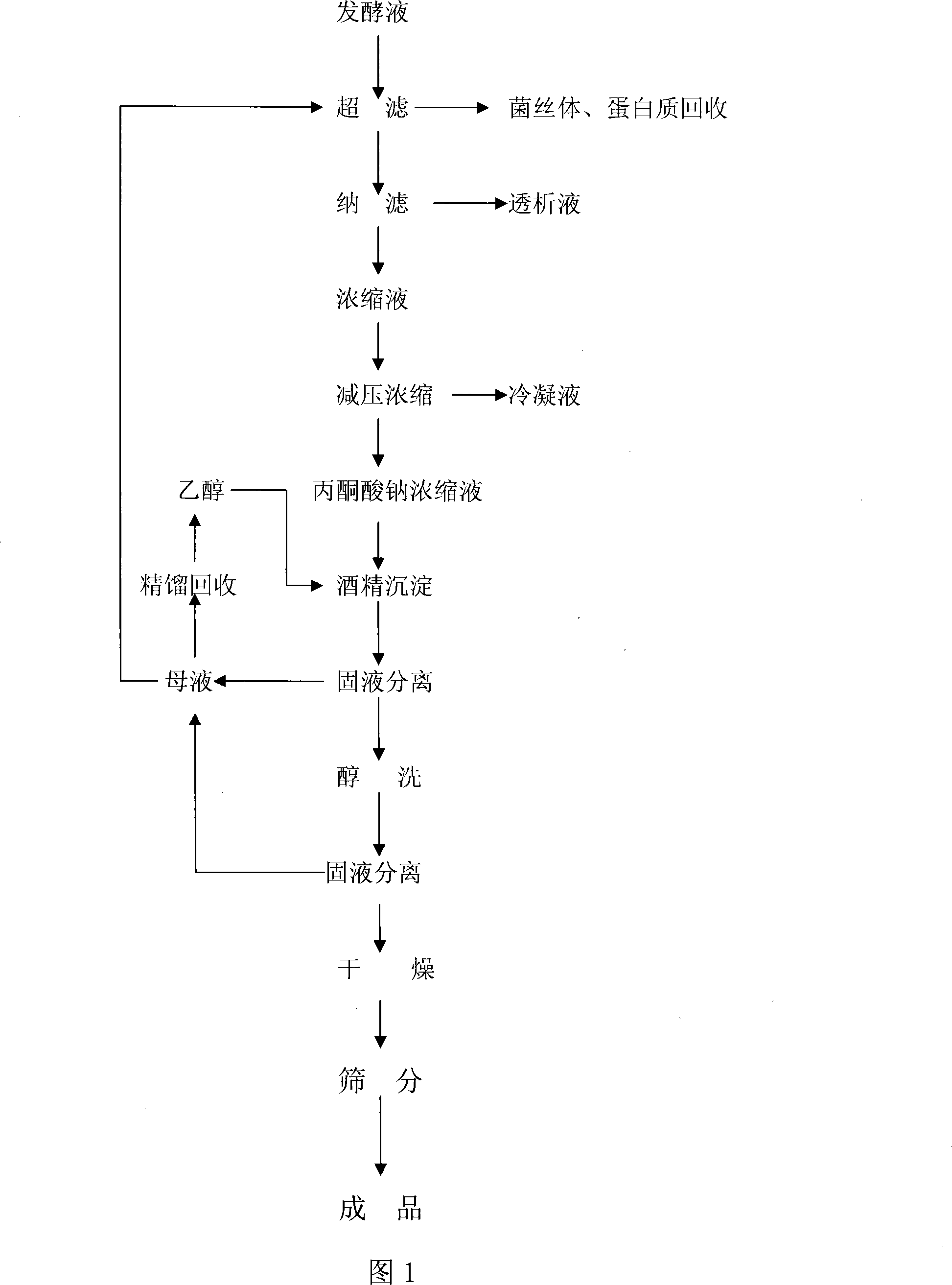

Method for extracting and separating sodium ketopropionate from acetonic acid fermentation liquid by double membrane two-step process

A technology of sodium pyruvate and pyruvic acid, applied in the separation/purification of carboxylic acid compounds, organic chemistry and other directions, can solve the problems of low yield, large pollution, long production lines, etc., to avoid low yield and avoid cumbersome steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Centrifugal filtration: The fermented pyruvic acid that has undergone ordinary filtration is pumped into a centrifuge for separation, and the centrifugate is input into a transfer storage tank as the raw material for the next step of ultrafiltration. (this step yield is 96.6%)

[0030] 2. Ultrafiltration and impurity removal: pump the centrifugate into the tubular ultrafiltration system for ultrafiltration and filtration, and continuously add pure water to dilute and rinse the concentrated solution to remove residual mycelium, protein, sugar, pigment and other biological macromolecules. Dialysate and ultrafiltration concentrate containing residual mycelium, protein, sugar, pigment and other biomacromolecules. The membrane material used for ultrafiltration is a polyethylene membrane with a molecular weight cut-off of 5000. The working conditions are: normal temperature, inlet pressure 3.5bar, outlet pressure 2.0bar.

[0031] 3. Concentration by nanofiltration: pump t...

Embodiment 2

[0037] 1. Centrifugal filtration: the same as in Example 1.

[0038] 2. Ultrafiltration and impurity removal: pump the filtrate of the pyruvic acid fermentation broth after centrifugal filtration into the flat ultrafiltration system for ultrafiltration and filtration, and continuously add pure water to dilute and rinse the concentrated solution to obtain ultrafiltration dialysate and ultrafiltration Concentrate. The membrane material used for ultrafiltration is a polyethersulfone membrane with a molecular weight cut-off of 10,000, and the working conditions are: normal temperature, inlet pressure 4.0bar, outlet pressure 3.0bar.

[0039] 3. Nanofiltration concentration: pump the ultrafiltration dialysate into the nanofiltration equipment for nanofiltration filtration and concentration to obtain the nanofiltration concentrate of pyruvic acid. The membrane module used for nanofiltration is a tubular membrane module, and the nanofiltration membrane material is a composite membran...

Embodiment 3

[0045] 1, centrifugal filtration: same as embodiment 1.

[0046] 2. Ultrafiltration and impurity removal: pump the pyruvate fermentation broth filtrate after centrifugation and separation of bacteria into the roll-type ultrafiltration system for ultrafiltration and filtration, and continuously add pure water to dilute and rinse the concentrated solution to obtain ultrafiltration dialysis of pyruvate liquid. The membrane material used for ultrafiltration is cellulose acetate membrane with a molecular weight cut-off of 200,000. The working conditions are: normal temperature, inlet pressure 4.5bar, outlet pressure 3.4bar.

[0047] 3. Concentration by nanofiltration: pump the ultrafiltration dialysis into the nanofiltration equipment for concentration by nanofiltration to obtain the concentrated solution of nanofiltration of pyruvic acid. The membrane module used for nanofiltration is a flat membrane module, and the nanofiltration membrane material is a polyethersulfone membrane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com