Adsorbent for low-concentration ethane separation and preparation thereof

An adsorbent, low-concentration technology, used in adsorption purification/separation, chemical instruments and methods, other chemical processes, etc., can solve the problems of low adsorption capacity, reduced adsorption selectivity, limited application range, etc., and achieves low desorption temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

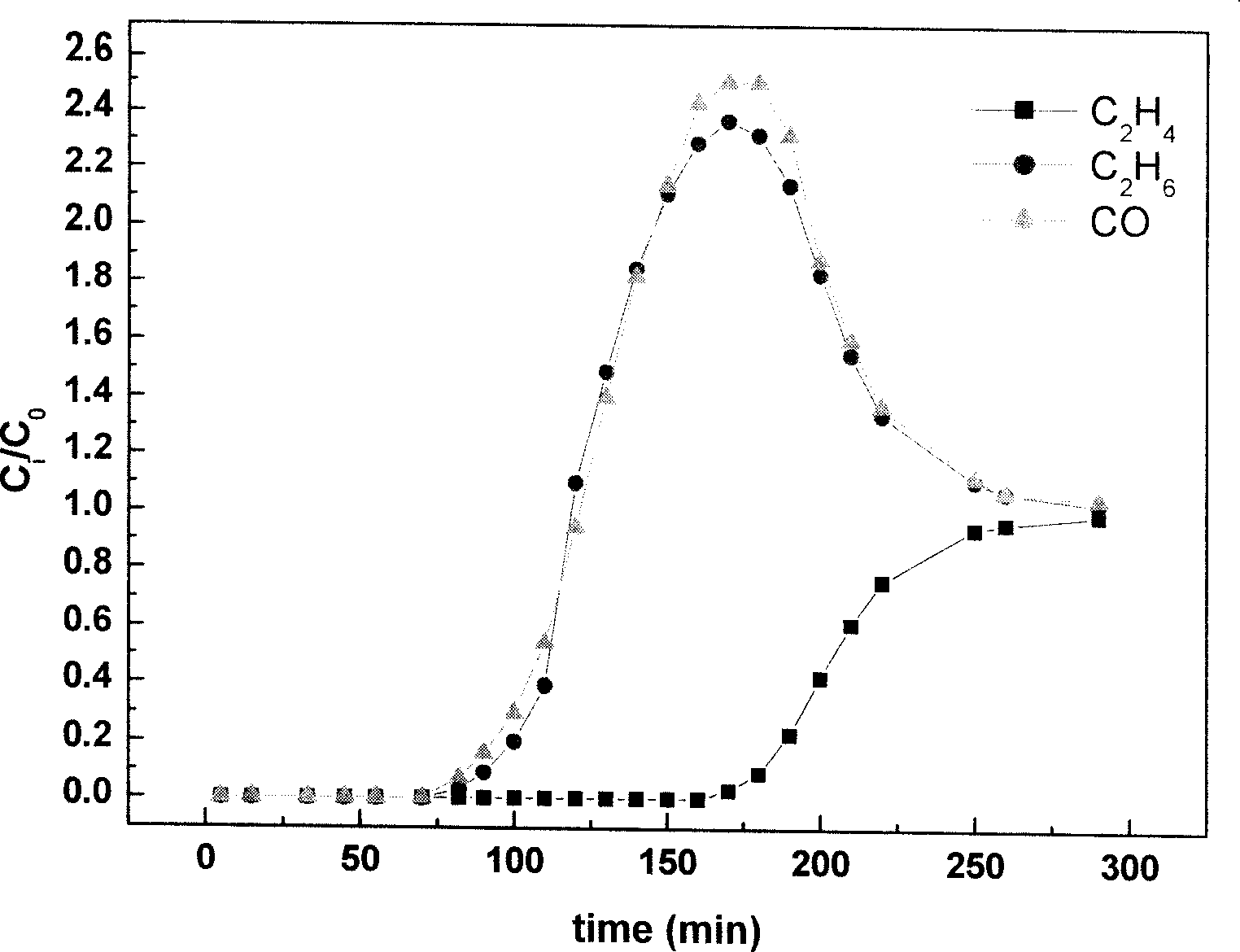

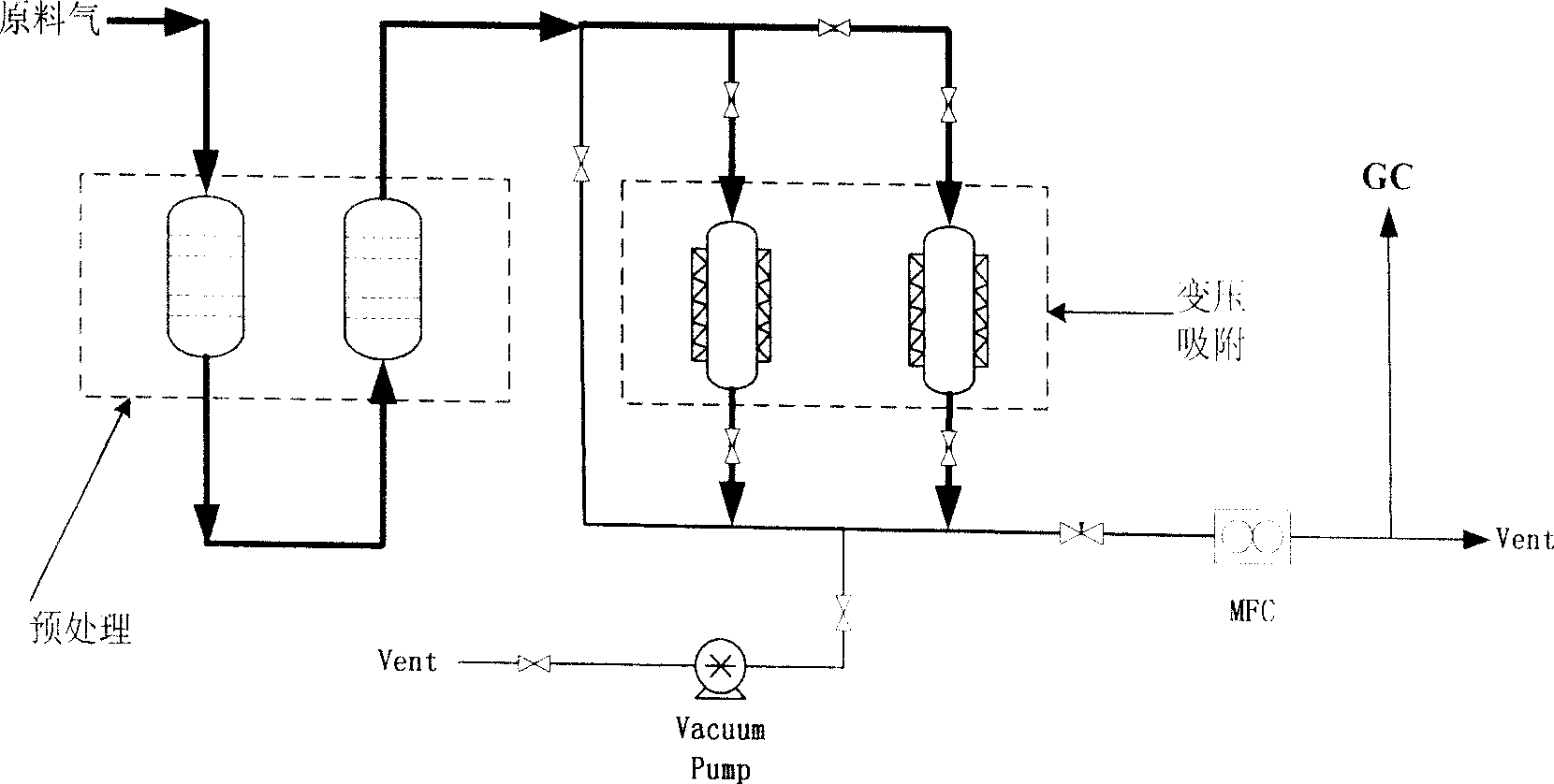

[0029] The specific surface area of 20g is 15m 2 / g of 4A molecular sieve was added to 250ml of CaCl containing 0.5mol / L at room temperature 2 In the aqueous solution, stir and reflux at 80°C for 4h. Filter, wash with deionized water three times, and dry the obtained precipitate at 120°C for 12h, then place it in a muffle furnace and bake at 350°C for 3h. The Ca content of the final adsorbent is 20%, and XRD test analysis shows that its structure is Ca-A molecular sieve. After tableting and sieving, take 10g of adsorbent with 20-40 meshes, figure 1 The gas is adsorbed, and the ethylene adsorption capacity of 2.0mmol / g and the carbon monoxide adsorption capacity of 0.2mmol / g can be obtained.

Embodiment 2

[0031] The specific surface area of 20g is 410m 2 / g of 13X molecular sieve was added to 250ml of CaCl containing 0.5mol / L at room temperature 2 In the aqueous solution, stir and reflux at 85°C for 3h. Filter, wash with deionized water three times, and dry the obtained precipitate at 120°C for 12h, then place it in a muffle furnace and bake at 380°C for 3h. The Ca content of the final adsorbent is 15%. After tableting and sieving, 10 g of the adsorbent of 20 to 40 meshes is taken, and the figure 1 The gas is adsorbed, and the ethylene adsorption capacity of 3.0mmol / g and the carbon monoxide adsorption capacity of 0.4mmol / g can be obtained.

Embodiment 3

[0033] The specific surface area of 20g is 330m 2 / g of 4A molecular sieve was added to 300ml of Ba(NO 3 ) 2 In the aqueous solution, stir and reflux at 90°C for 2h. Filter, wash with deionized water three times, and dry the obtained precipitate at 120°C for 12h, then place it in a muffle furnace and bake at 400°C for 2h. The final Ba content of the adsorbent is 15%. After tableting and sieving, 10 g of the adsorbent of 20 to 40 meshes is taken, and the adsorbent is prepared under normal pressure and room temperature with an attached figure 1 The gas is adsorbed, and the ethylene adsorption capacity of 2.8mmol / g and the carbon monoxide adsorption capacity of 0.3mmol / g can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com