Continuous-blending muller

A grinding machine and mixing chamber technology, applied in the direction of mixers, fluid mixers, mixer accessories, etc., can solve the problems of small processing capacity, intermittent operation, complex process, etc., to reduce equipment investment and floor space, improve mixing Grinding efficiency and the effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

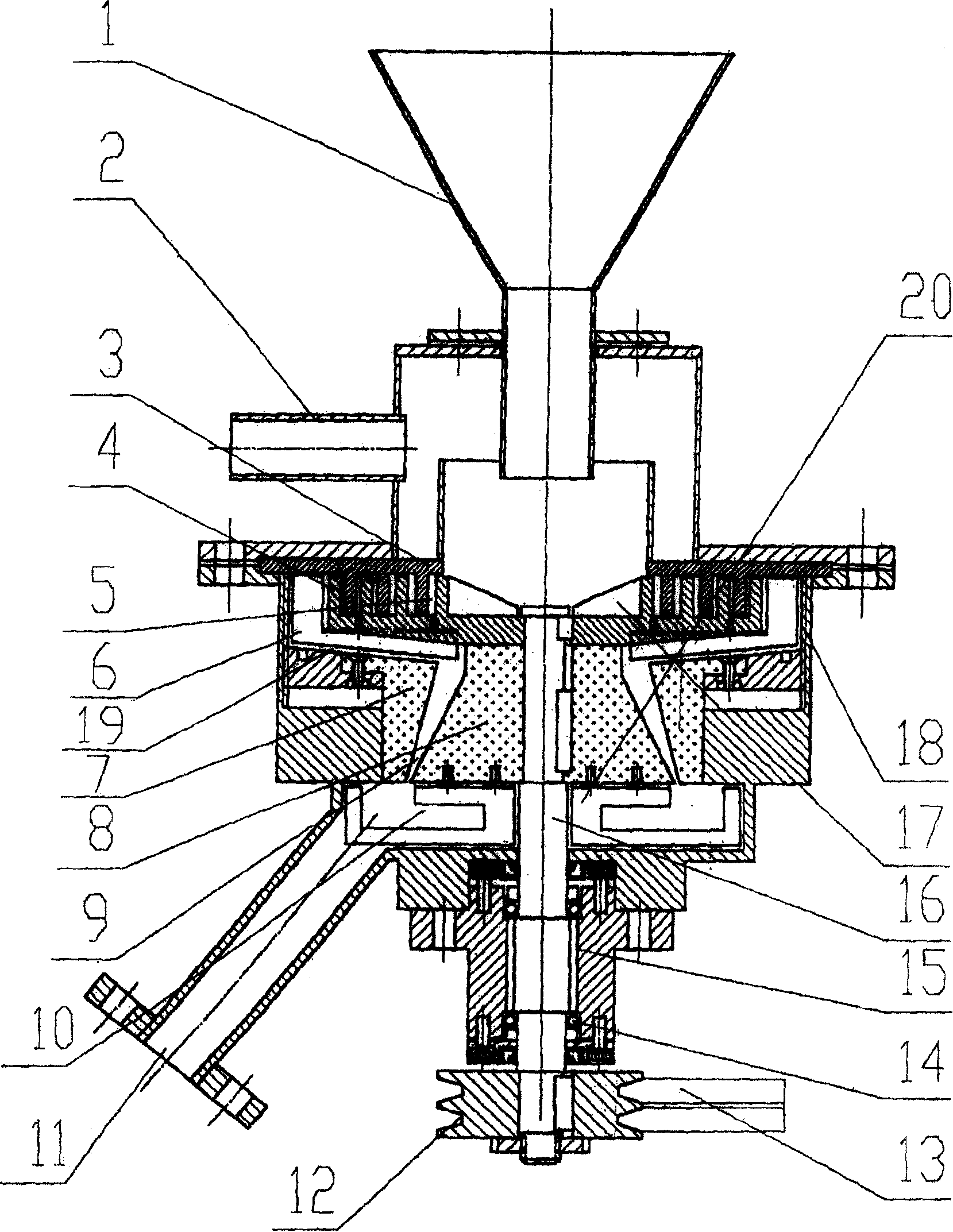

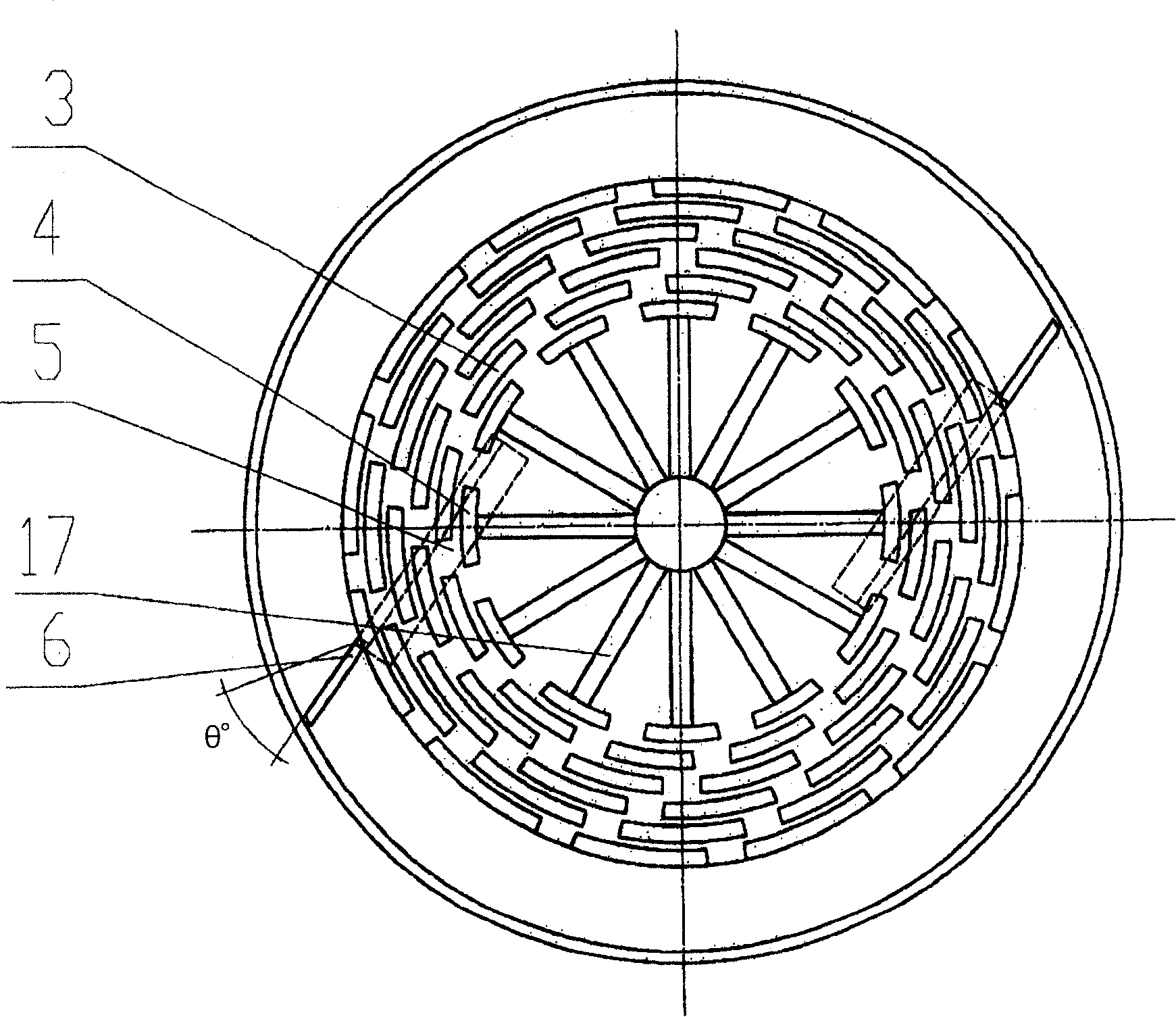

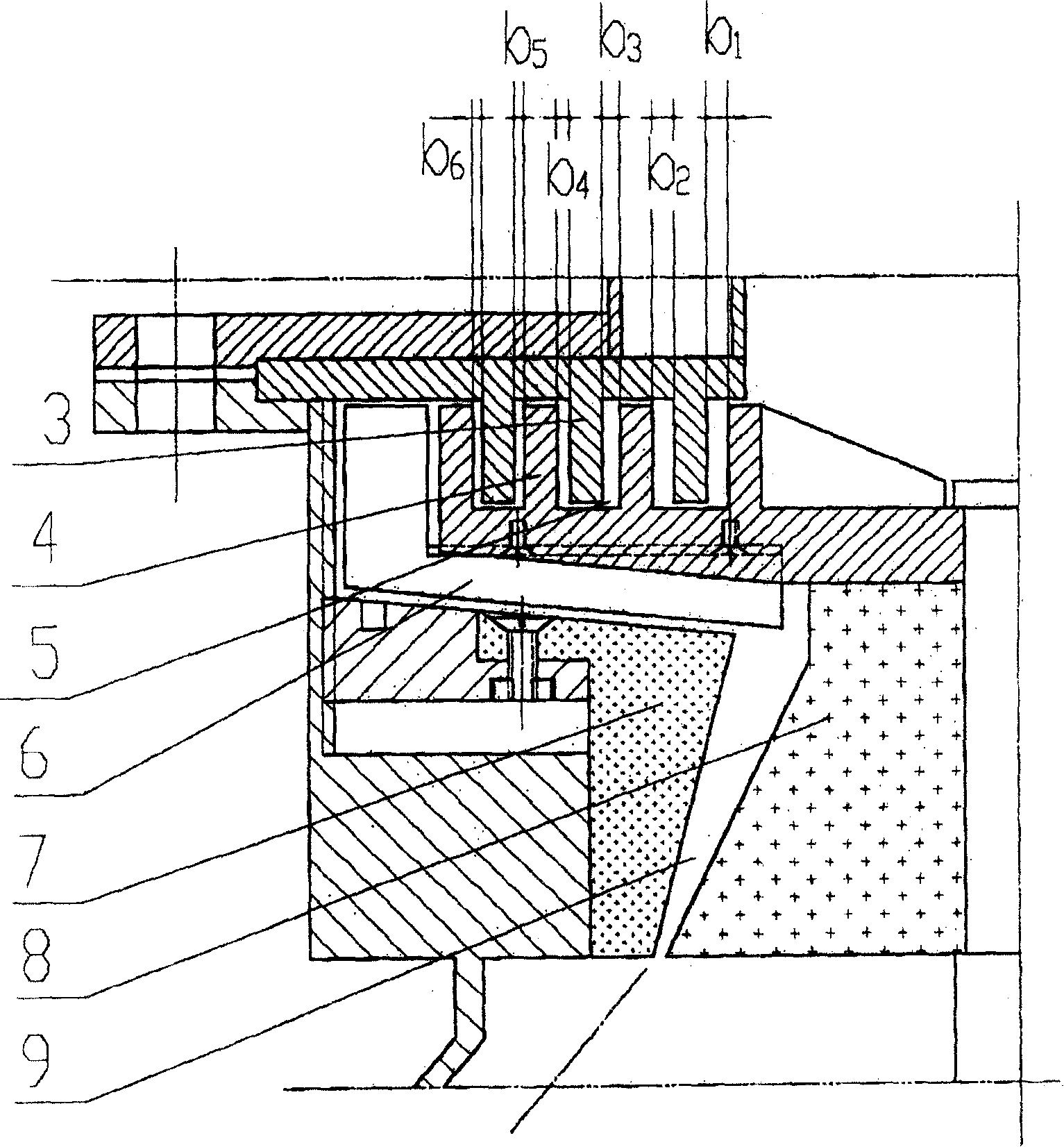

[0041] This embodiment illustrates: the continuous mixing-grinding machine provided by the present invention is used to uniformly mix solid powder and liquid and grind them into fine-grained colloids.

[0042] The structure of the continuous mixing-grinding machine adopted in the present embodiment is as follows: figure 1 Shown: the inner diameter of the mixing device shell is 200mm, the shell height is 450mm, the tooth height of the mixing stator 3 and the mixing rotor 4 is 20mm, the mixing stator 3 is composed of 3 layers of teeth, and the mixing rotor 4 is composed of 4 layers of teeth, each layer For 20 teeth. Radially outward from the center of the rotating shaft 16, the gaps between the teeth of the hybrid stator 3 and the teeth of the hybrid rotor 4 are respectively b1=3.5mm, b2=3.mm, b3=2.5mm, b4=b5=b6= 2.0mm. Two scrapers 6 symmetrically arranged on the bottom circumference of the mixing rotor 4 are used. The gap between the two scrapers 6 and the inner wall of the ...

Embodiment 2

[0047] In this example, the same continuous mixing-grinding machine as in Example 1 was used to grind the cracking catalyst fine powder. The source of the powder was the fine powder produced when the cracking catalyst was prepared in this laboratory, and the particle size distribution of the powder was 5-60 μm, wherein The average particle size is about 28 μm.

[0048] As a result, 400kg of colloid was produced, the solid content of the colloid was 40%, the particle size of the colloid was 0.8-5.5 μm, and the average particle size of the colloid was 1.8 μm. Two people were required to operate the system, the production time was 1.5 hours, the electricity consumption was 8.5 degrees, and the cleaning water Be 20 liters, use about 195kg of raw material (its solid content is about 84%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com