Steam generation plant and method for operation and retrofitting of a steam generation plant

A technology for generating equipment and steam generators, which is applied in steam engine installations, mechanical equipment, lighting and heating equipment, etc., and can solve the problem of realizing investment costs only after 20 years.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

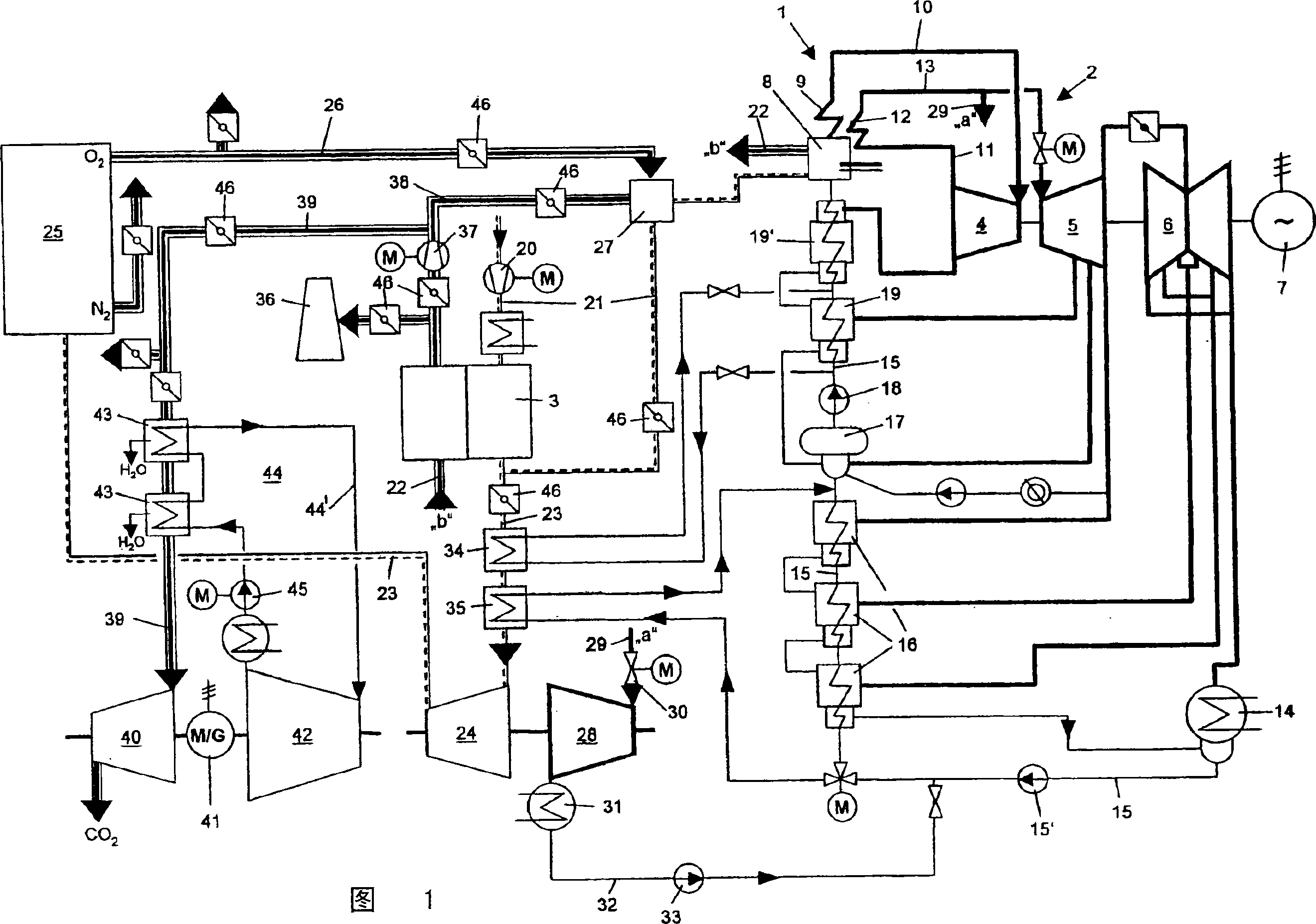

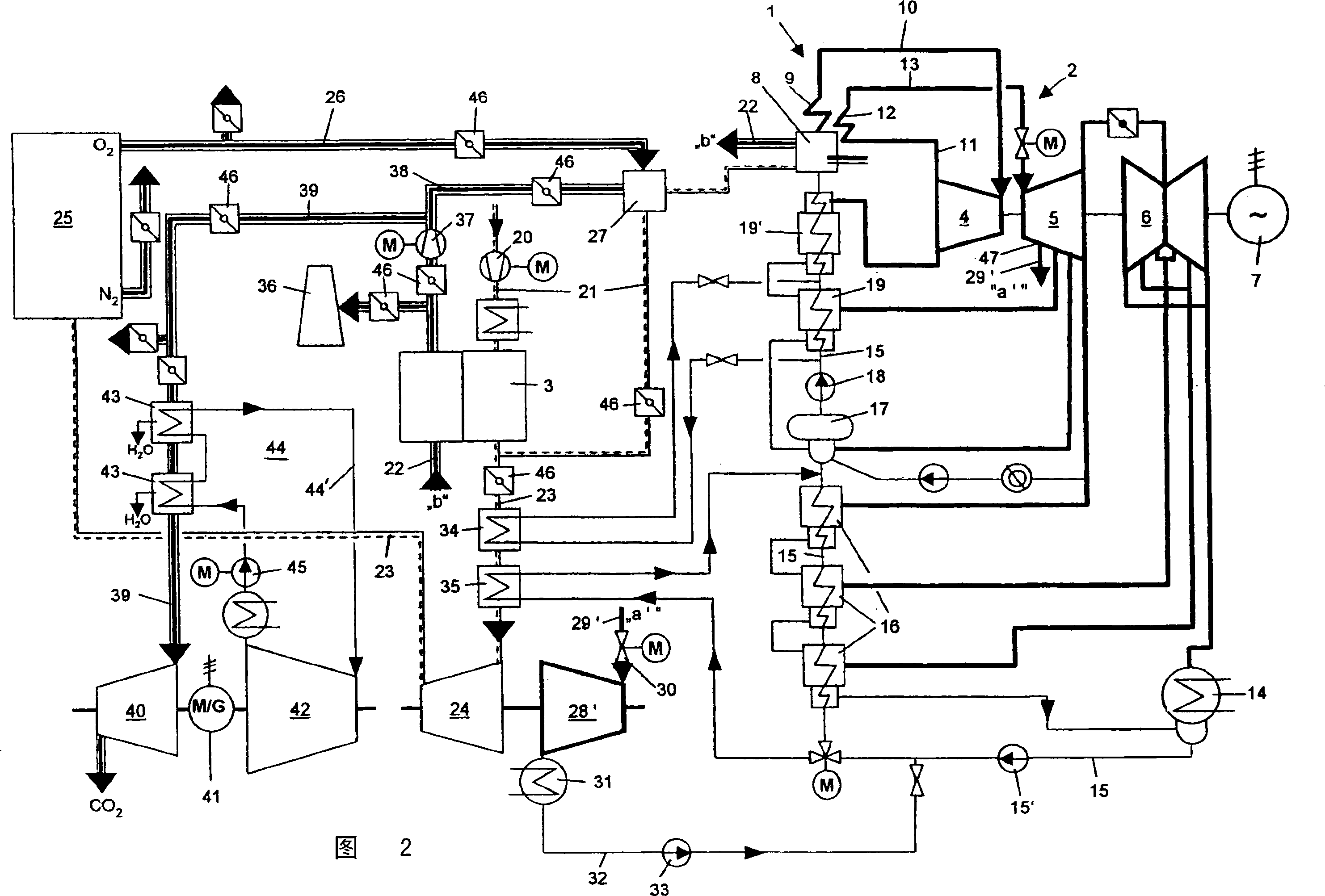

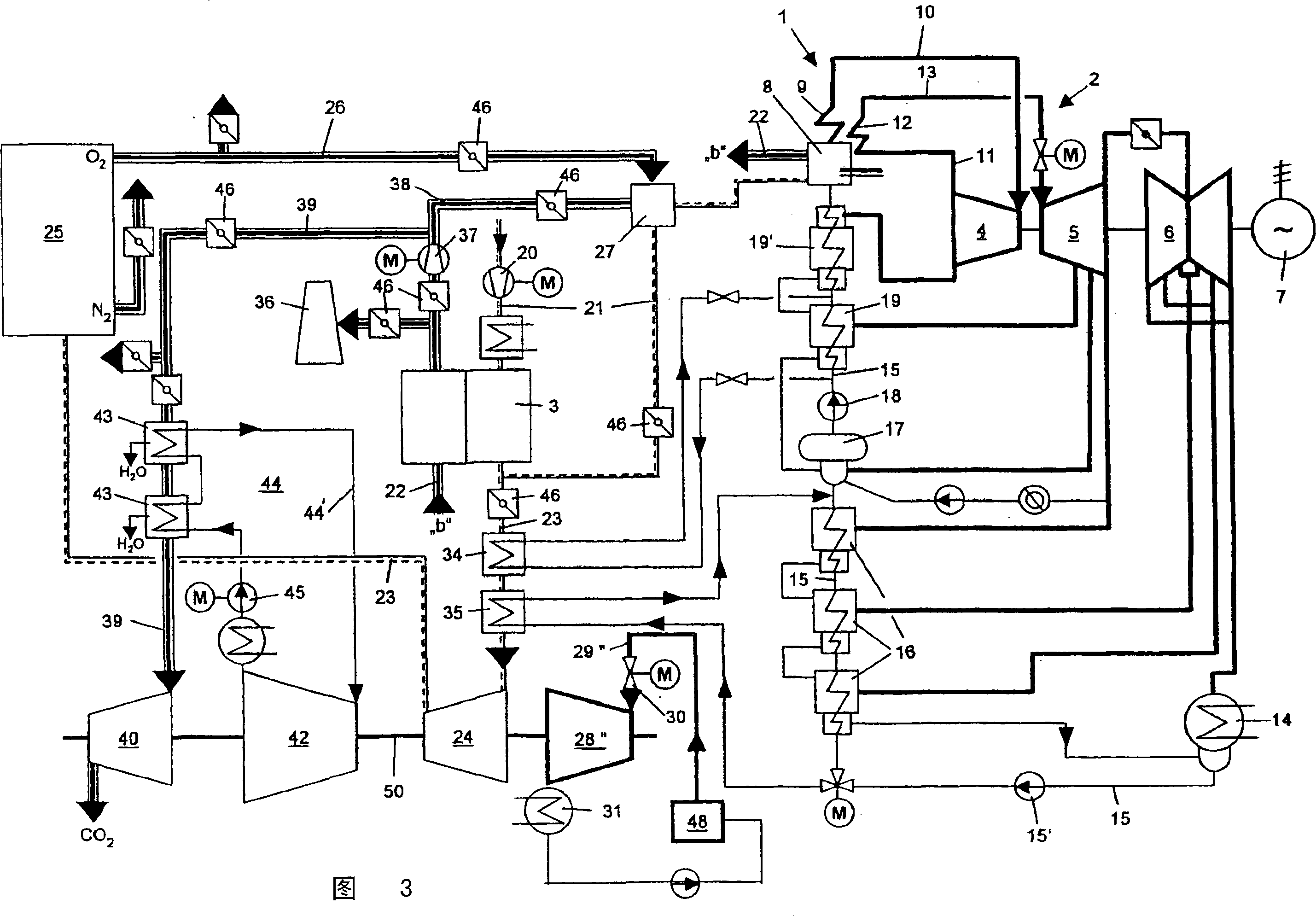

[0011] The steam generating plant comprises a steam generator 1 with a water-steam circuit, a steam turbine unit 2 as well as an air supply system, a flue gas discharge system and a regenerative air preheater heated by the flue gas (hot blast preheater 3 ). In this regard, the steam generating plant is of conventional construction type. What follows is only a brief explanation of the invention in terms of aspects necessary for understanding it.

[0012] The steam turbine unit 2 comprises a high-pressure part 4 , a medium-pressure part 5 and a low-pressure part 6 , which are arranged on a common shaft and drive a generator 7 for generating electrical energy.

[0013] The steam generator 1 shown is a forced continuous steam generator. The following descriptions also apply to drum boilers. The steam generator 1 has a combustion chamber 8 with a furnace chamber operated with gaseous fuel. In principle, operation on coal is also possible, taking into account the use of a flue ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com