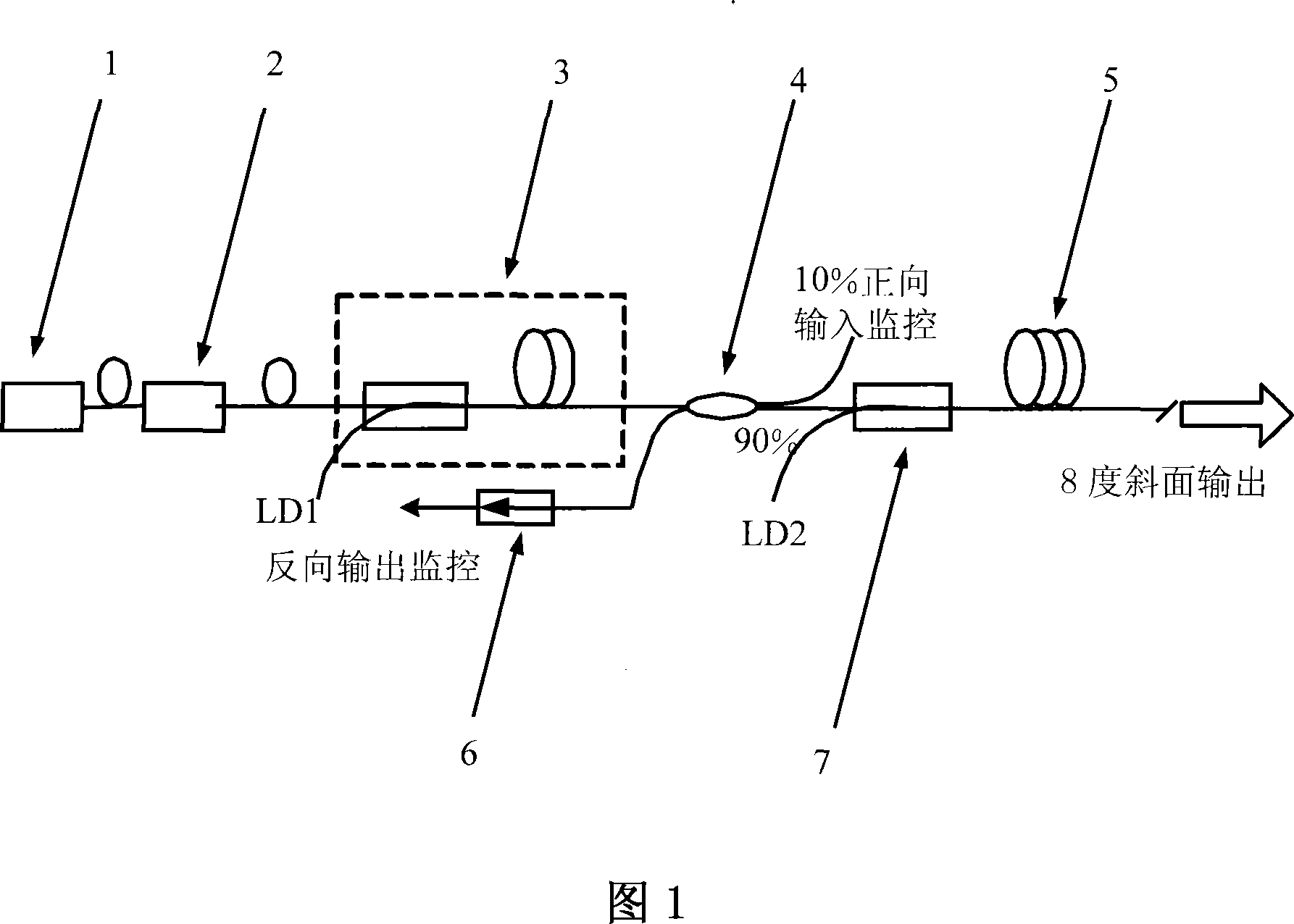

Whole optical fiber narrow linewidth hundred billisecond pulse signal system

A pulse signal and narrow linewidth technology, applied in cladding optical fiber, optics, lasers, etc., can solve the problems of pulse shape distortion, difficult coupling adjustment, limited fiber energy, etc., and achieve the effect of narrow linewidth and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0020] Embodiment 2, the difference compared with embodiment 1 is that the output terminal of described ytterbium-doped double-clad fiber amplifier 5 is connected to a high-power fiber isolator, such as a fiber isolator of > 3W, which can greatly improve the overall The stability of the system, the output structure of the fiber optic isolator is easier to package, and can meet the requirements of narrow line width, high power and output pulse waveform without distortion in more occasions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com