Environmental protection paper structure for foods container and manufacture method thereof

A food container and manufacturing method technology, applied in textiles, papermaking, paper, papermaking, etc., can solve the problems of thick film layer, sticking, easy to produce embrittlement, etc., so as to reduce production and personnel costs and shorten manufacturing time. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

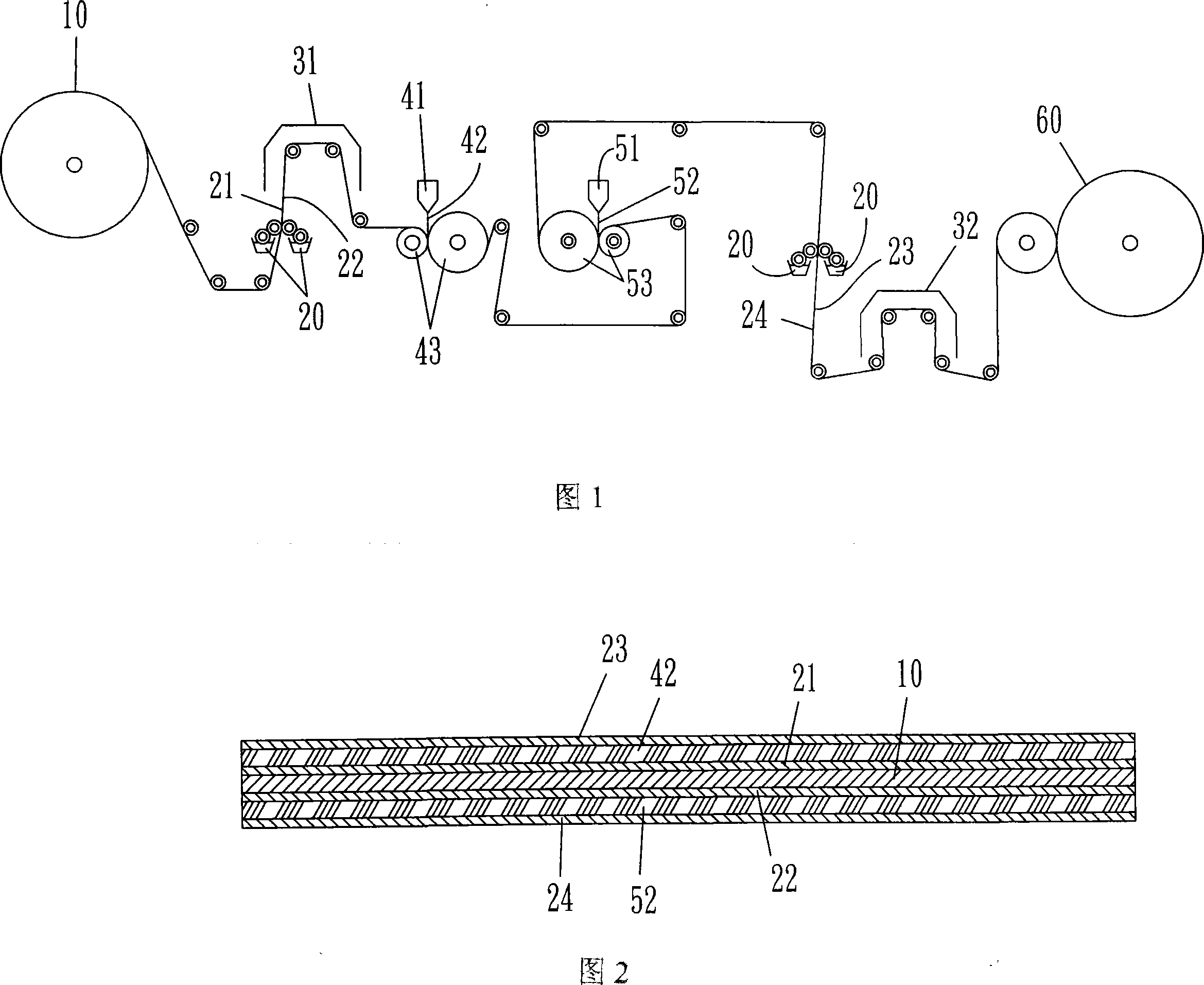

[0010] As shown in the accompanying drawings 1 and 2, the manufacturing method of the present invention includes the following process: the base paper roll paper layer 10 is conveyed by a rotary wheel, and the two sides are coated with an adhesive 20 for food packaging by roller set roll printing. For the upper and lower first bridging agent coatings 21, 22, the adhesive is made of a biodegradable material with good viscous effect, such as FEPOL material or other materials with similar properties. Then use the first drying device 31 to make the double-sided and lower first bridging agent coatings 21, 22 finalized, then on the first bridging agent coating 21 surface, carry out the first extrusion first time with the laminating machine 41 The biodegradable film layer 42 is covered (positioned on the upper end face), and pressed into one body with the cooling roller group 43, and then the second bridging agent coating 22 surface is carried out with another group of laminating mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com