Method for preparing high-purity chloro-cyclic carbonates

A cyclic carbonate and chlorinated technology, applied in the field of compound preparation, can solve the problems of lack of high-purity neutral chlorinated cyclic carbonate preparation method, low purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

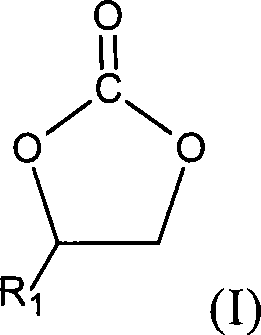

[0051] The method for preparing high-purity chlorinated cyclic carbonate of the present invention, the method comprises the following steps:

[0052] (a) Provide cyclic carbonate and chlorination reagent raw materials;

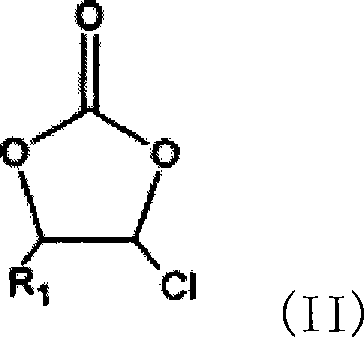

[0053] (b) performing a photocatalytic chlorination reaction on the raw materials in step (a) in the presence of specific ultraviolet light to generate chlorinated cyclic carbonates. The specific ultraviolet light refers to the light emitted by the ultraviolet light source with an intensity of 300-2000w and a light wavelength of 300-360nm.

[0054] Further, the above preparation method may optionally include step (c): neutralizing the chlorinated cyclic carbonate obtained in step (b) to obtain a neutral chlorinated cyclic carbonate.

[0055] Each processing condition or parameter of above-mentioned method is described in detail below:

[0056] Cyclic Carbonate Raw Materials

[0057] Cyclic carbonate of the present invention can be ethylene carbonate, propy...

Embodiment 1

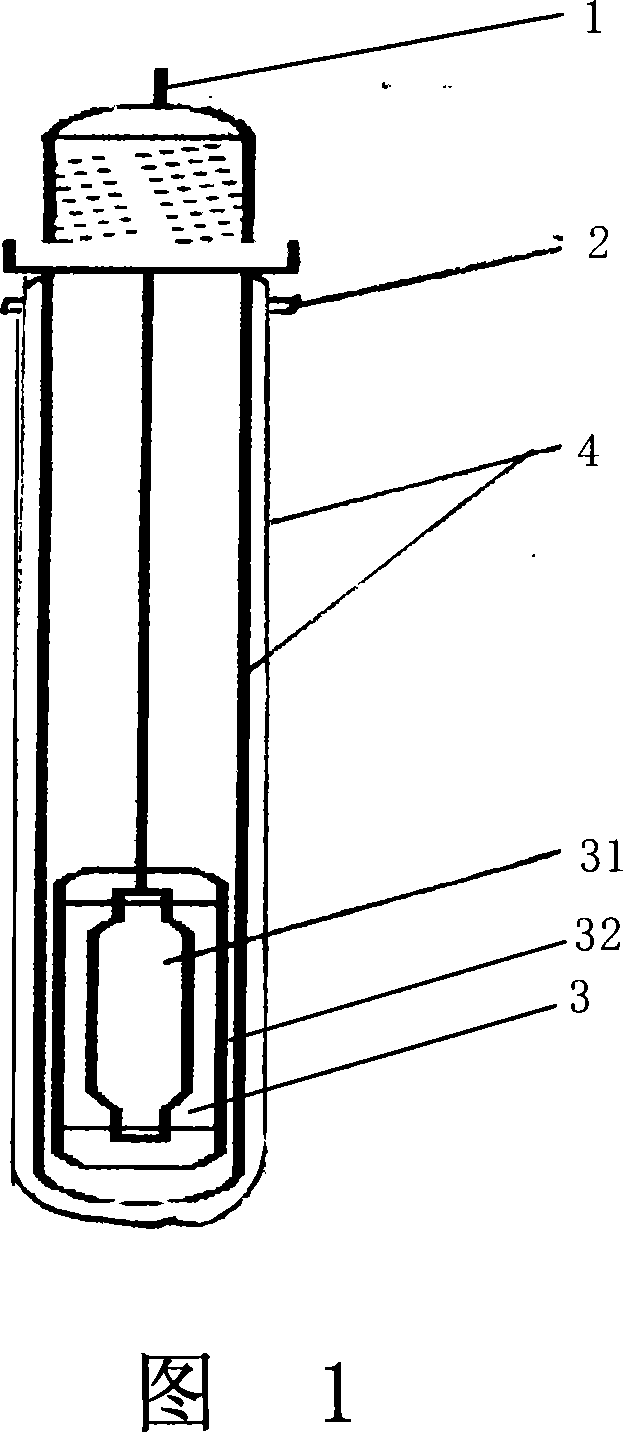

[0117] In the quartz bottle that is filled with ethylene carbonate 352g (4mol), maintain the negative pressure in the bottle as -0.02kPa, feed chlorine 4mol bubbling at 50 DEG C and start the ultraviolet light source as shown in Figure 1 (light intensity, 300W; wavelength, 300nm) for 24 hours. Cool and replace by blowing nitrogen gas for 1 hour to obtain 480 g of reaction liquid. Analysis of the components of the reaction liquid by gas chromatography (GC-2014, Shimadzu) revealed that the reaction liquid was 93.18% by weight of 4-chloro-1,3-dioxolan-2-one.

[0118] To the filtrate obtained as above, 240 g of 10% by weight sodium bicarbonate aqueous solution was added dropwise, stirred for 0.5 hour, static, layered, the lower floor neutral filtrate obtained had a pH value of 7, dried over anhydrous magnesium sulfate, and the filtrate obtained by filtration was reduced Pressure rectification, collect 80-120 ℃ / (2-5kPa) fraction 430g, analyze by GC / MS mass spectrometry, m / z: 122, ...

Embodiment 2

[0128] In the quartz bottle filled with ethylene carbonate 352g (4.00mol), maintain the negative pressure in the bottle to be-0.08kPa, feed 16mol chlorine bubbles at 70°C and start the ultraviolet light source as shown in Figure 1 (light intensity, 500w; wavelength, 360nm, water layer thickness 2mm) keep warm for 24 hours. Cool and replace by blowing nitrogen gas for 1 hour to obtain 480 g of reaction liquid. Analysis of the components of the reaction liquid by gas chromatography (GC-2014, Shimadzu) revealed that the reaction liquid was 92.68% by weight of 4-chloro-1,3-dioxolan-2-one.

[0129] To the filtrate obtained above, 960 g of 10% by weight of sodium bicarbonate aqueous solution was added dropwise, stirred for 0.5 hour, static, layered, the obtained lower floor neutral filtrate, the pH value was 7, dried over anhydrous magnesium sulfate, and the filtrate obtained by filtration was carried out Vacuum rectification, 423g of fractions at 80-120°C / 2-5kPa were collected, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com