Fluid flow control system of gas foaming agent

A flow control and gas foaming technology, applied in flow control, control/regulation systems, non-electric variable control, etc., to solve problems such as unstable flow measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

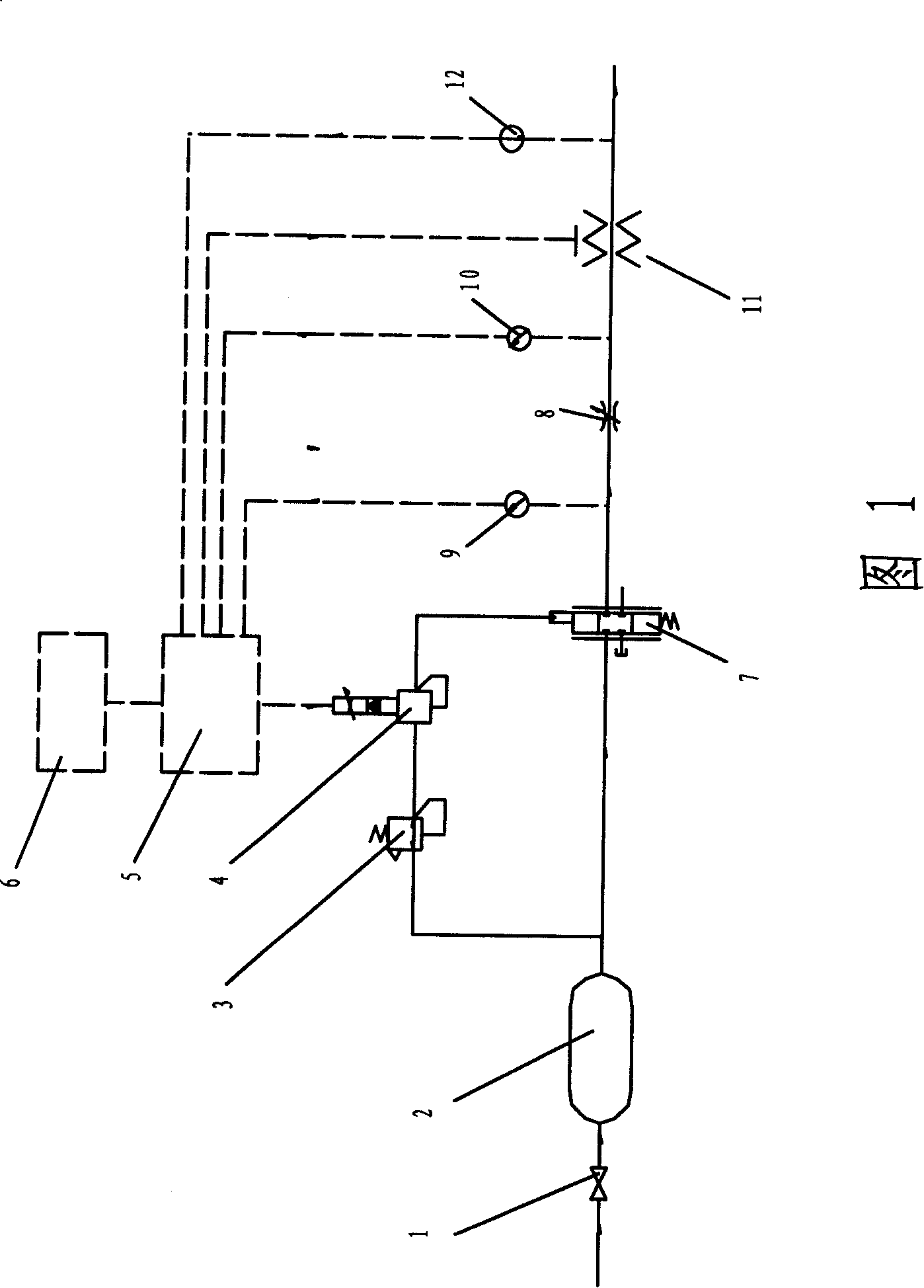

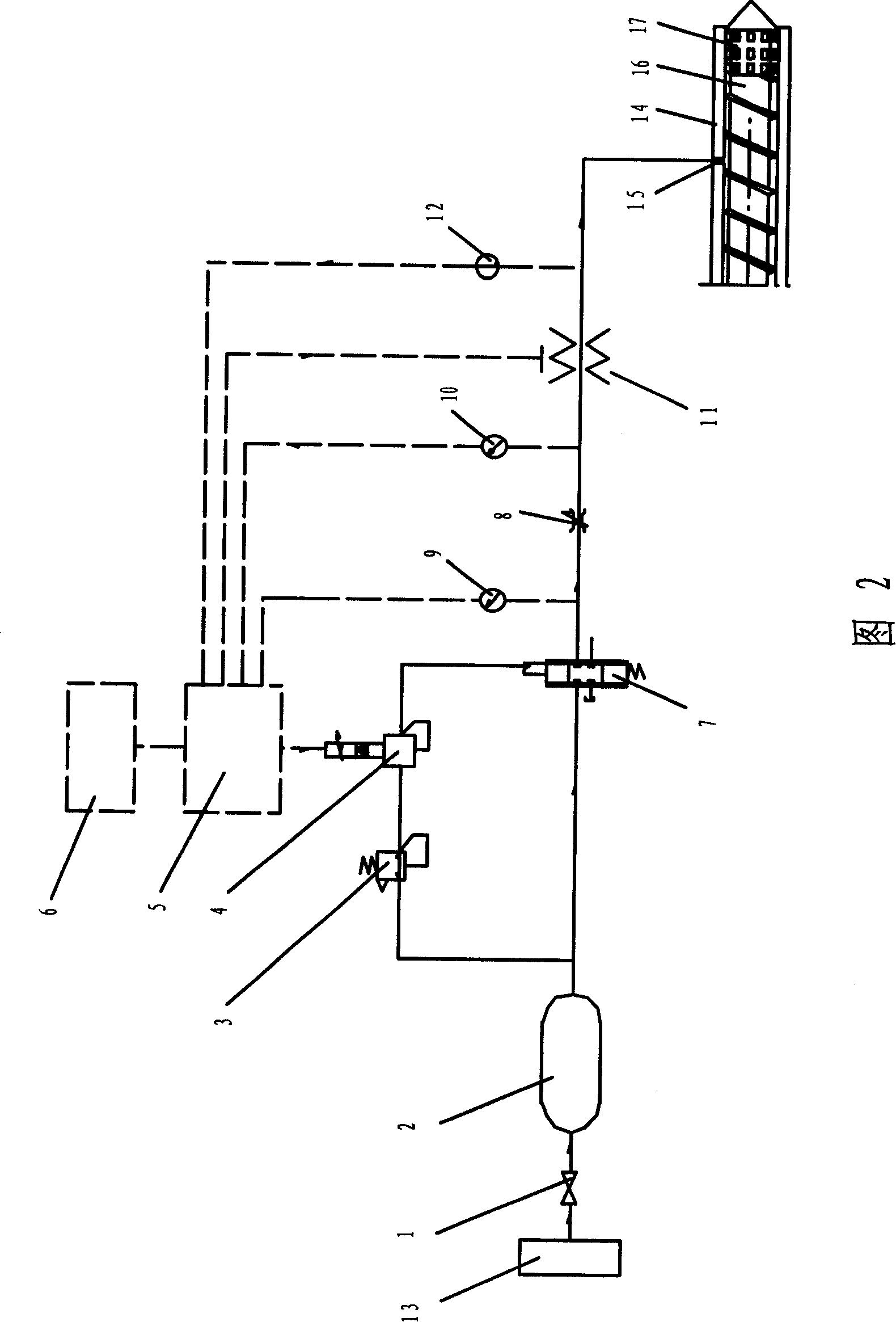

[0010] Below in conjunction with accompanying drawing, feature of the present invention and related features are further described by embodiment:

[0011] As shown in Figures 1 and 2, the labels 1-17 represent respectively, 1-stop valve, 2-high pressure container, 3-pressure reducing valve, 4-electromagnetic proportional valve stop valve, 5-data processing and control module, 6- Operation interface, 7-high pressure servo valve, 8-adjustable throttle valve, 9 and 10-pressure sensor, 11-foaming agent temperature control module, 12-temperature sensor, 13-high pressure air source, 14-resin processing device Barrel, 15-foaming agent inlet, 16-screw, 17-mixing element.

[0012] As shown in accompanying drawings 1 and 2, the system of the present invention includes an inlet shut-off valve 1, a high-pressure container 2, a pressure reducing valve 3, an electromagnetic proportional valve 4, a high-pressure servo valve 7, an adjustable throttle valve 8, pressure sensors 9 and 10, Foami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com