Unit type vacuum moisture regaining loosening technique

A vacuum moisture resurfacing and unitized technology, which is applied in the fields of tobacco preparation, application, tobacco, etc., can solve the problems of tobacco leaves not being easy to penetrate, uneven permeability, and waste energy, so as to ensure the penetration rate and uniform penetration performance, shortening the time of vacuum resurfacing treatment, and alleviating the effect of temperature and moisture loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

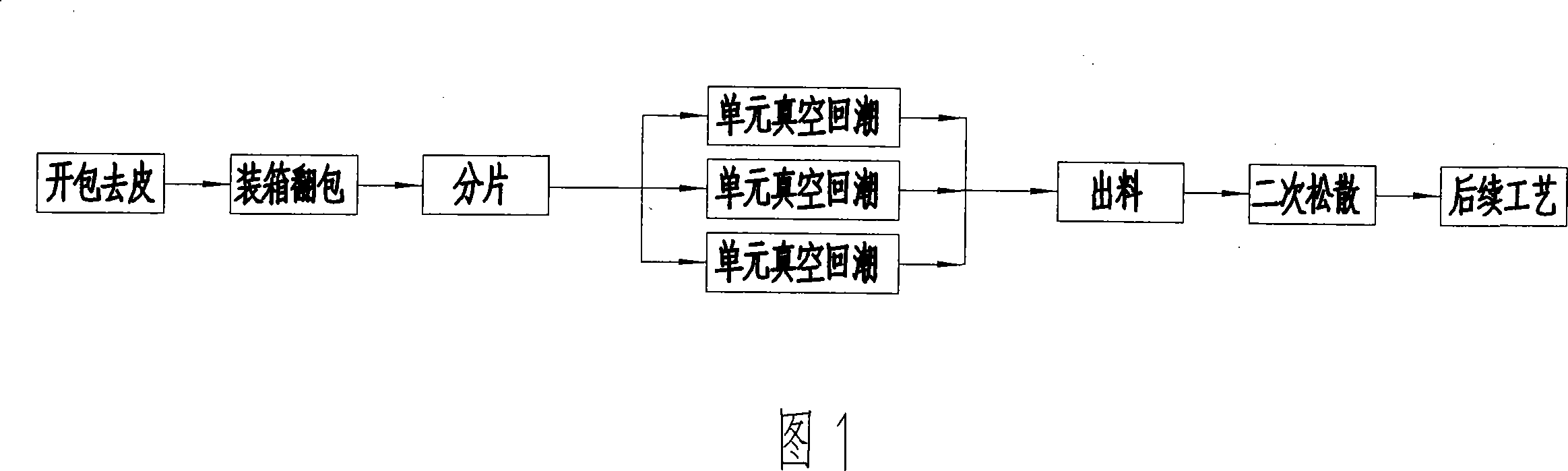

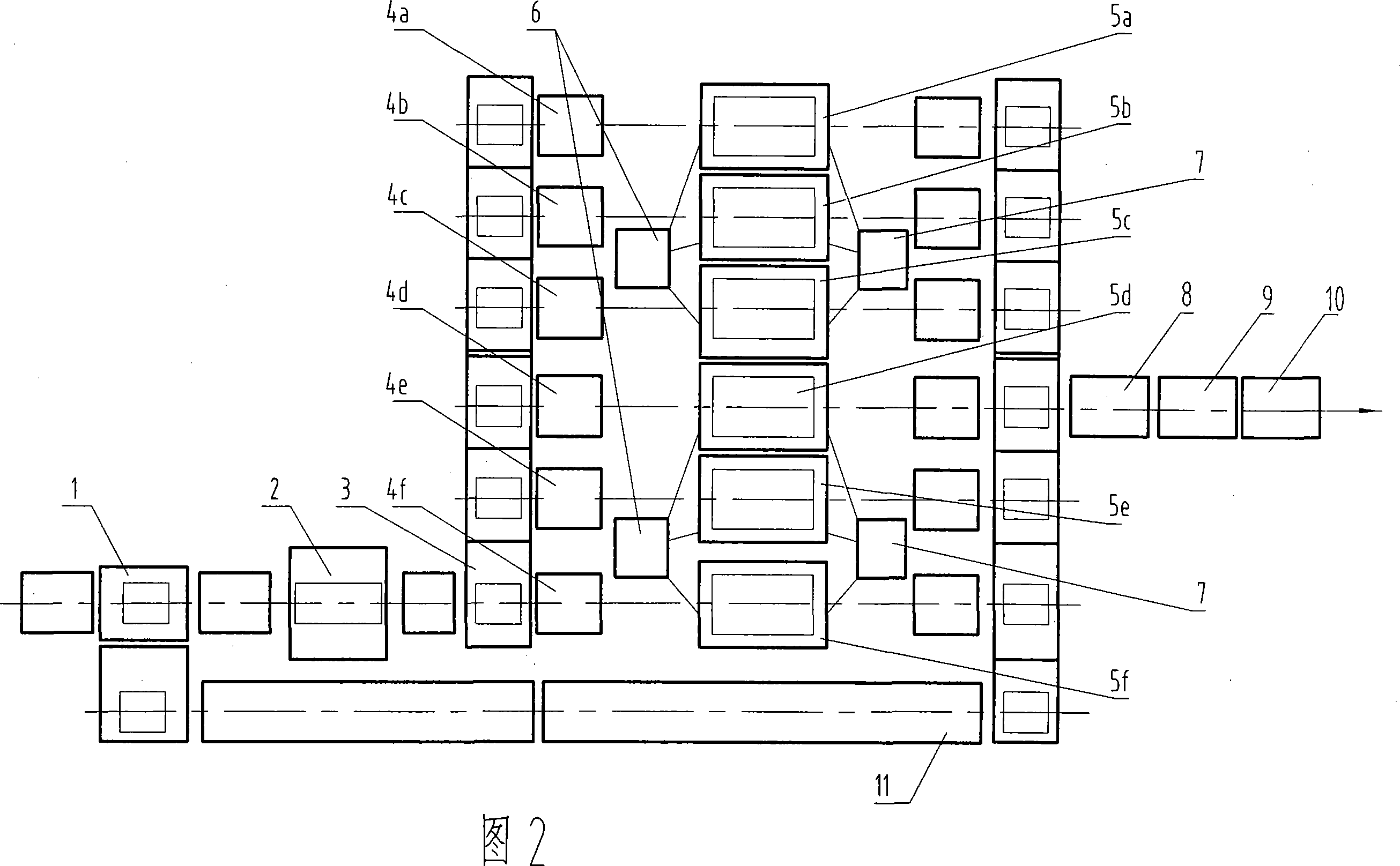

[0023] The invention can be used to carry out vacuum moisture regain treatment on stacked tobacco on the threshing and redrying line, and can also be used to carry out vacuum moisture regain treatment on cigarette packs on the silk making line. As shown in Fig. 1, it is a process flow for performing vacuum moisture resurfacing treatment on laminar tobacco packs on the silk making line. The unpacked and peeled cigarette packs are loaded into steel turnover boxes through the box-packing and turning-over device, and one inner cigarette pack is loaded into one turnover box. The slicing device divides the cigarette packs in the steel turnover box into slices with a thickness not greater than 200mm, and then through the logistics equipment, the steel turnover boxes containing the smoke slices are sent to each parallel vacuum moisture resurgence unit in sequence. Vacuum dampening treatment, one vacuum dampening unit box is sent into one turnover box at a time. Lamina bales processed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com