Heat-resisting shading sheet, manufacturing method thereof, and diaphragm and light quantity adjusting device using the same

A manufacturing method and technology of shading sheets, applied in aperture, chemical instruments and methods, optics, etc., can solve problems such as residue, large thermal deformation, and mutual contact, and achieve the effects of reducing manufacturing costs, improving sliding properties, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

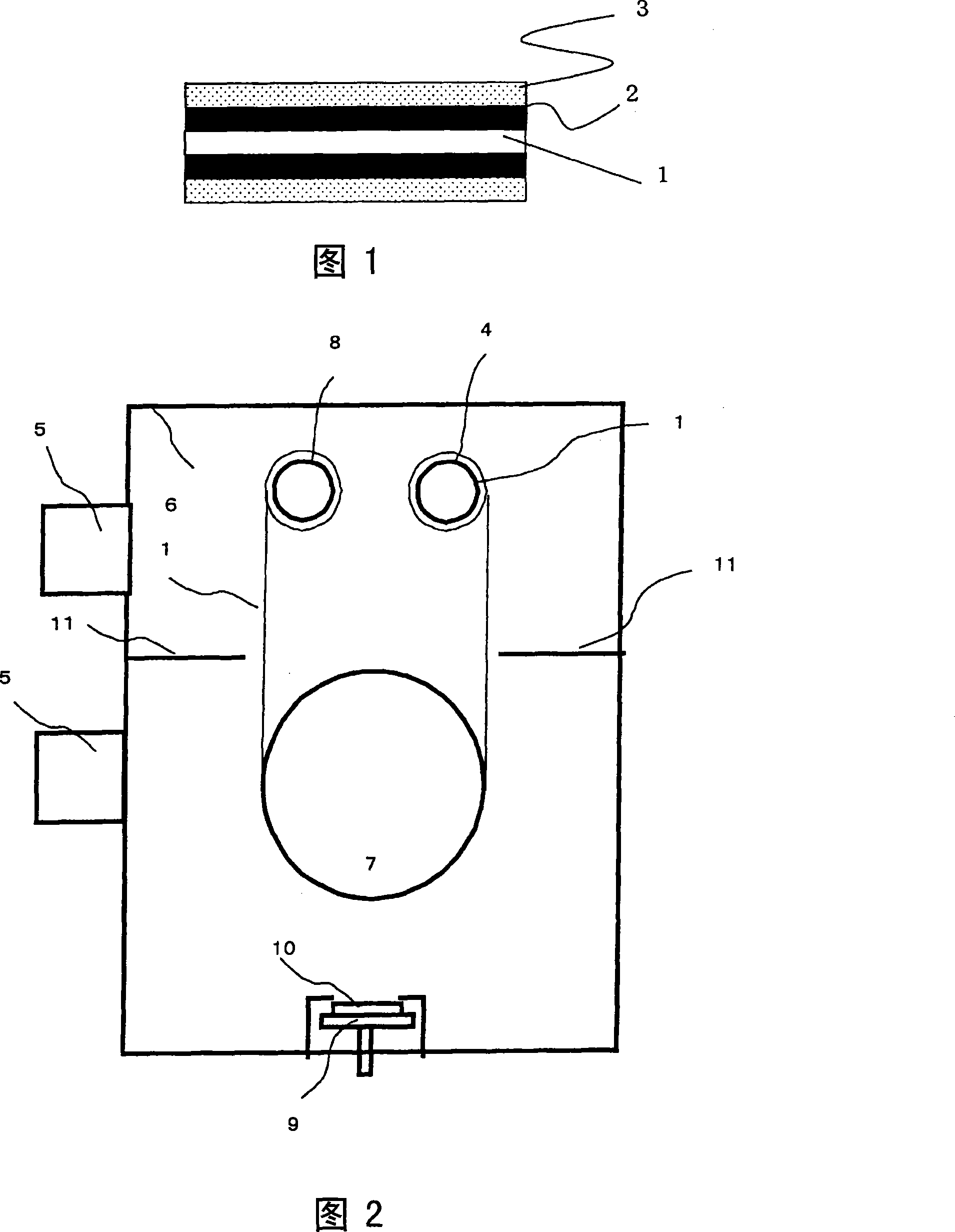

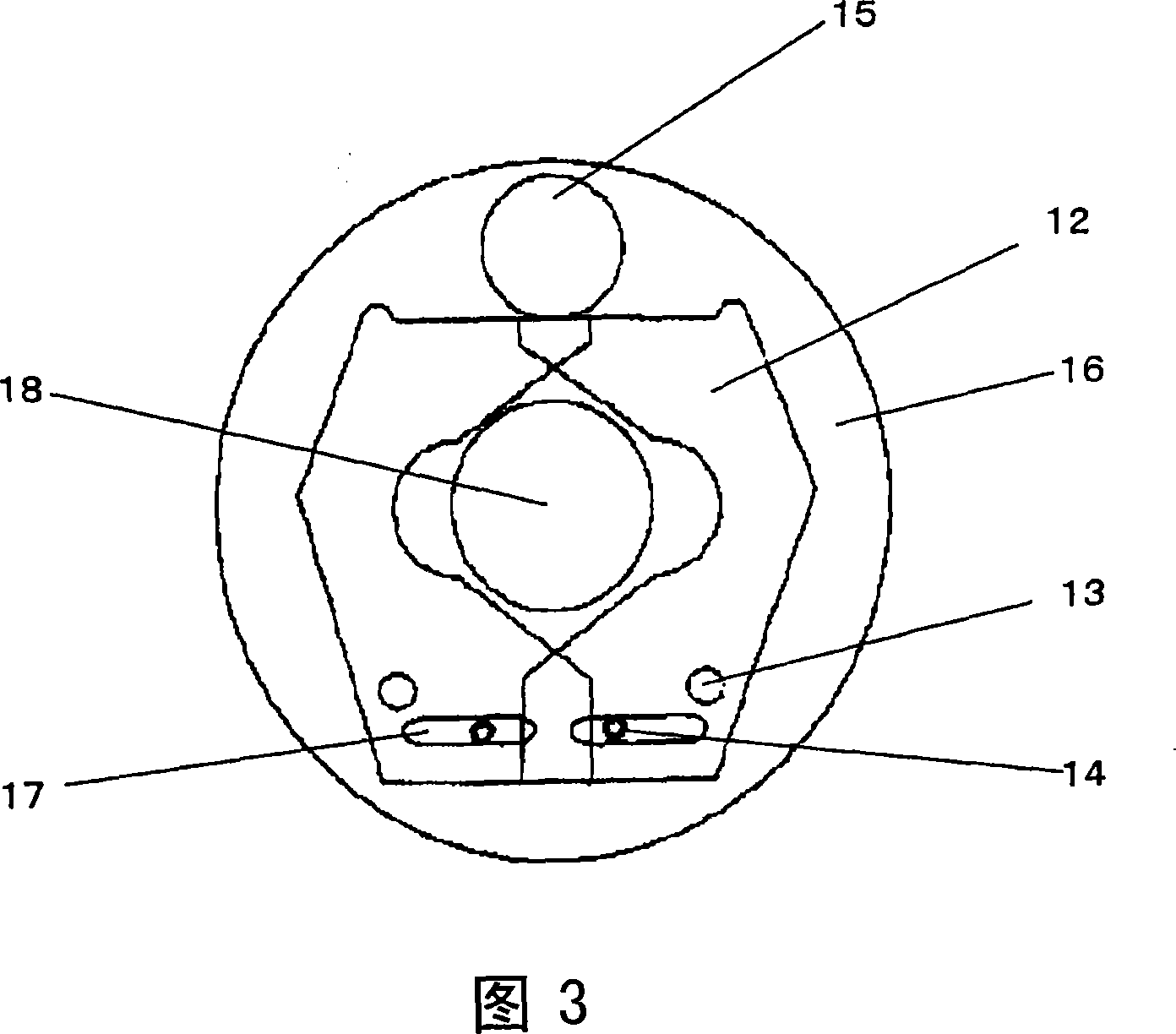

[0139] The metal light-shielding sheet and the metal oxide film were formed using a take-up sputtering device as shown in FIG. 2 . First, a target 10 as a film raw material is set on the cathode of the device provided with the magnetron cathode 9 on the side opposite to the surface of the cooling tank drum 7 . The sheet conveyance section composed of the unwinding roller 4 , the cooling tank roller 7 , the take-up roller 8 and the like is separated from the magnetron cathode 8 by the partition 11 . Then, the cylindrical resin sheet base material 1 is set on the unwinding roll 4 . The surface of the polyimide (PI) sheet was blasted at a predetermined spraying time, spraying pressure, and conveying speed to form fine irregularities with an arithmetic average height Ra of 0.5 μm on both surfaces. The polyimide (PI) sheet is dried by heating to a temperature above 200° C. before sputtering.

[0140] Then, after the inside of the vacuum chamber 6 is evacuated by a vacuum pump 5 s...

Embodiment 2

[0147] A heat-resistant light-shielding sheet was fabricated under exactly the same conditions as in Example 1 except that only the thickness of the metal film was changed to 50 nm.

[0148] The evaluation (optical performance, heat resistance) of the obtained heat-resistant light-shielding sheet was performed by the same method and conditions as Example 1. When carrying out the sputtering of the metal film and the oxide film in the same manner as in Example 1, the surface temperature of the sheet is measured by the quartz glass window of the take-up sputtering device by an infrared radiation thermometer, and the temperature is 180-220° C. Example 1 Equivalent flake temperature.

[0149]As a result, properties such as optical density, reflectance, and gloss were at the same level as those in Example 1. In addition, it was confirmed that the surface resistance value was 120 Ω / □, and the arithmetic average height Ra of the surface was 0.4 μm. In addition, in the adhesive evalu...

Embodiment 3

[0152] A heat-resistant light-shielding sheet was produced under exactly the same conditions as in Example 1 except that only the thickness of the metal film was changed to 150 nm.

[0153] The evaluation (optical performance, heat resistance) of the obtained heat-resistant light-shielding sheet was performed by the same method and conditions as Example 1. When carrying out the sputtering of the metal film and the oxide film in the same manner as in Example 1, the surface temperature of the sheet is measured by the quartz glass window of the take-up sputtering device by an infrared radiation thermometer, and the temperature is 180-220° C. Example 1 Equivalent flake temperature.

[0154] As a result, properties such as optical density, reflectance, and gloss were at the same level as those in Example 1. In addition, it was confirmed that the surface resistance value was 90Ω / □, and the arithmetic average height Ra of the surface was 0.3 μm. In addition, in the adhesive evaluat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com