Gas distribution piston for small-sized hot-air engine

A technology of gas distribution piston and hot air engine, applied in the field of engine piston, can solve the problems such as the inability to fundamentally solve the problem of piston radiation, heat conduction and conduction heat transfer, increase the amplitude of the temperature gradient, and poor heat conduction performance, and achieve simple structure and reduced heat transfer. Small vertical size, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

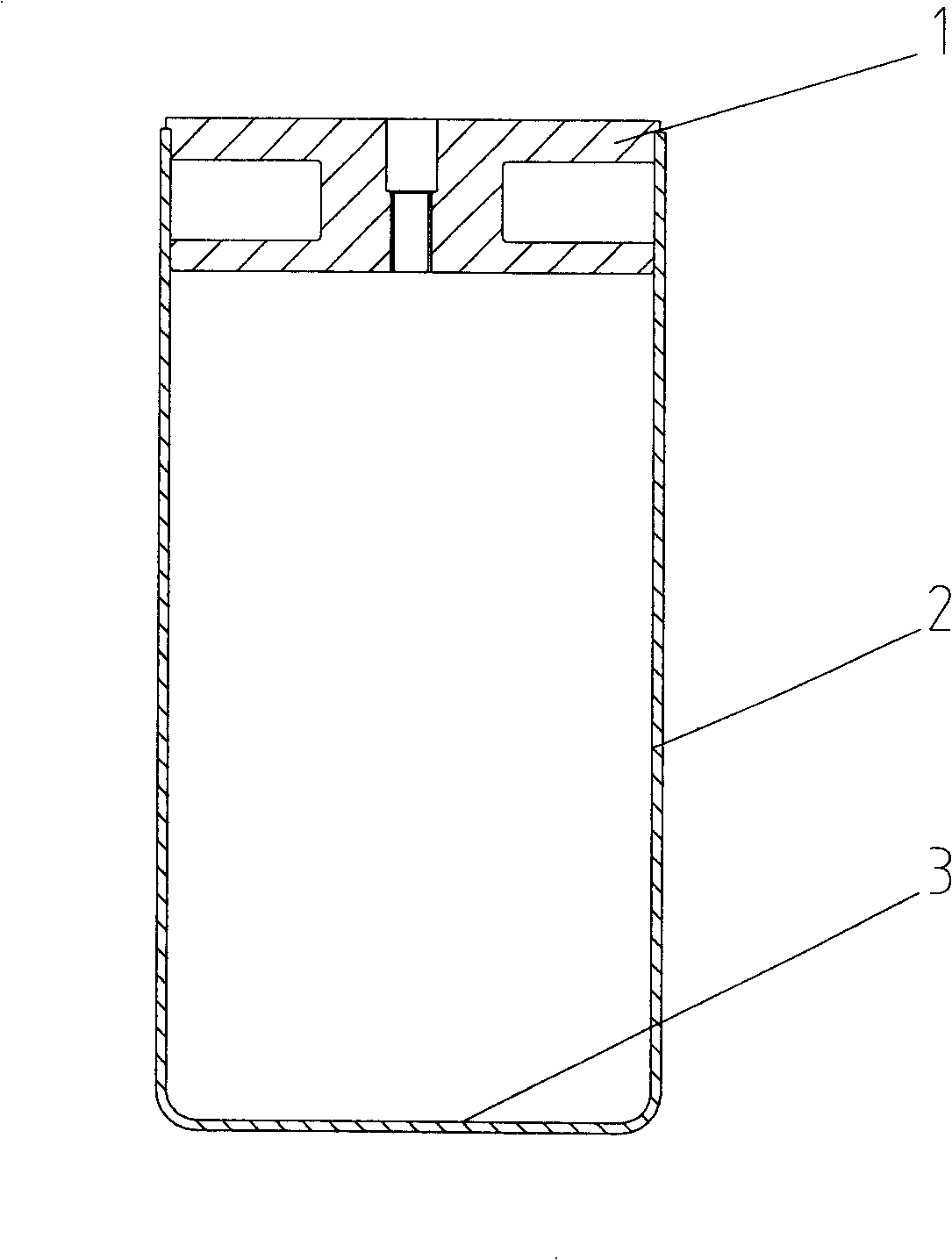

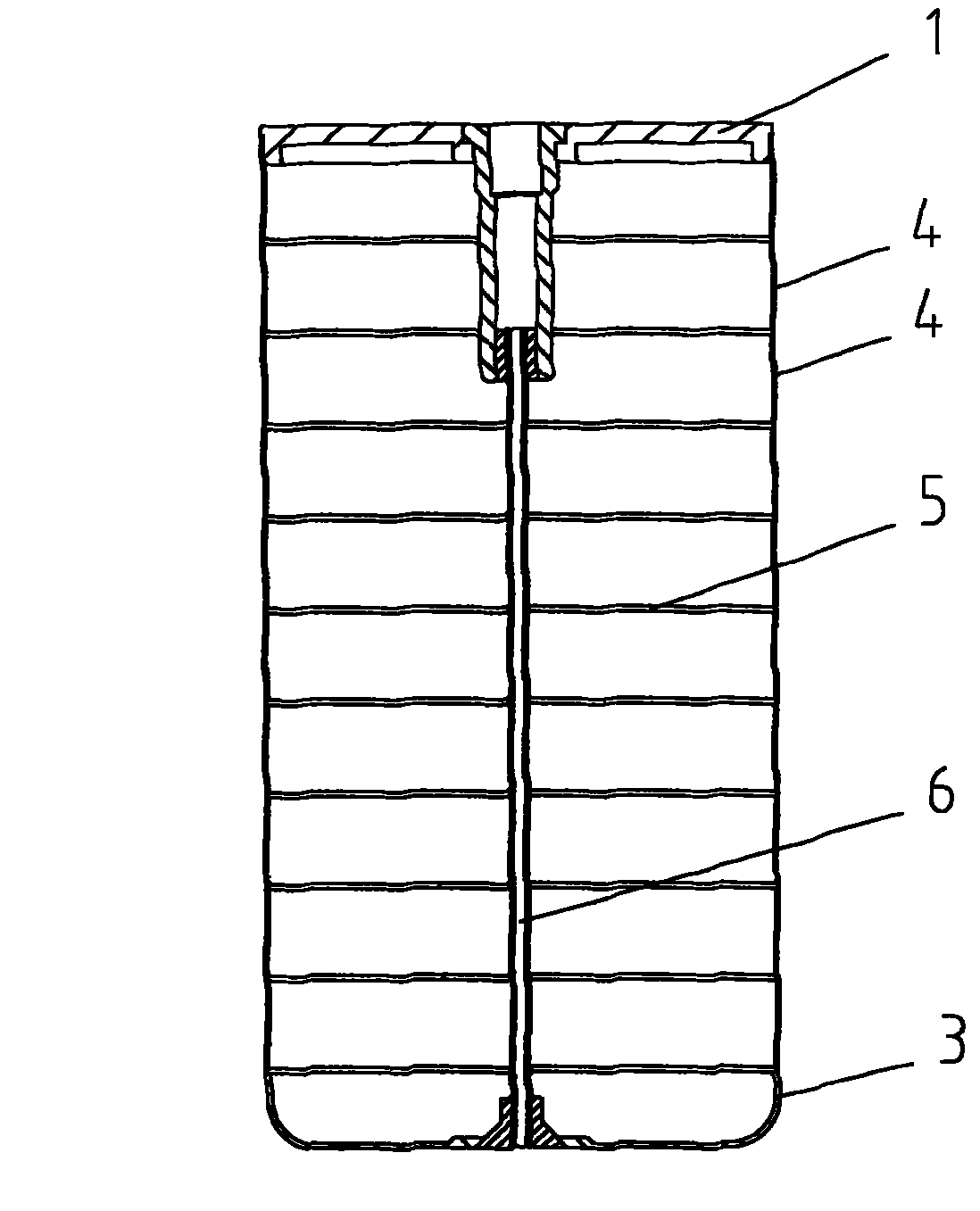

[0019] figure 1 Shown is the structural diagram of the gas distribution piston of a traditional small heat engine, which is composed of a piston seat 1, a piston body 2 and a piston top 3, the piston body 2 and the piston top 3 are thin-walled cylindrical structures, and the top of the piston top 3 is closed ;The piston body 2 and the piston top 3 are often made of an integral structure, which is stamped from a thin-walled stainless steel plate, or processed from a bar; the piston seat 1 and the piston body 2 are usually fixed by welding, bonding or threaded connection connect. Because the top 3 ends of the gas distribution piston are in direct contact with the heater, the maximum temperature can often reach 500-700°C. Its structural parameters and its own thermal resistance, weight and other performance indicators have a direct impact on the performance of the heater. Therefore, for small The hot air machine needs to meet the following points:

[0020] a) as small a mass as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com