Method of composite electroosmosis, vacuum precipitation and vacuum preload reinforcement foundation and device thereof

A vacuum and electroosmosis technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of combined water discharge, treatment of foundation bearing capacity, limited soil range, etc., to achieve direct discharge effect and increase soil mass. Pores, avoid the effect of rainwater recharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

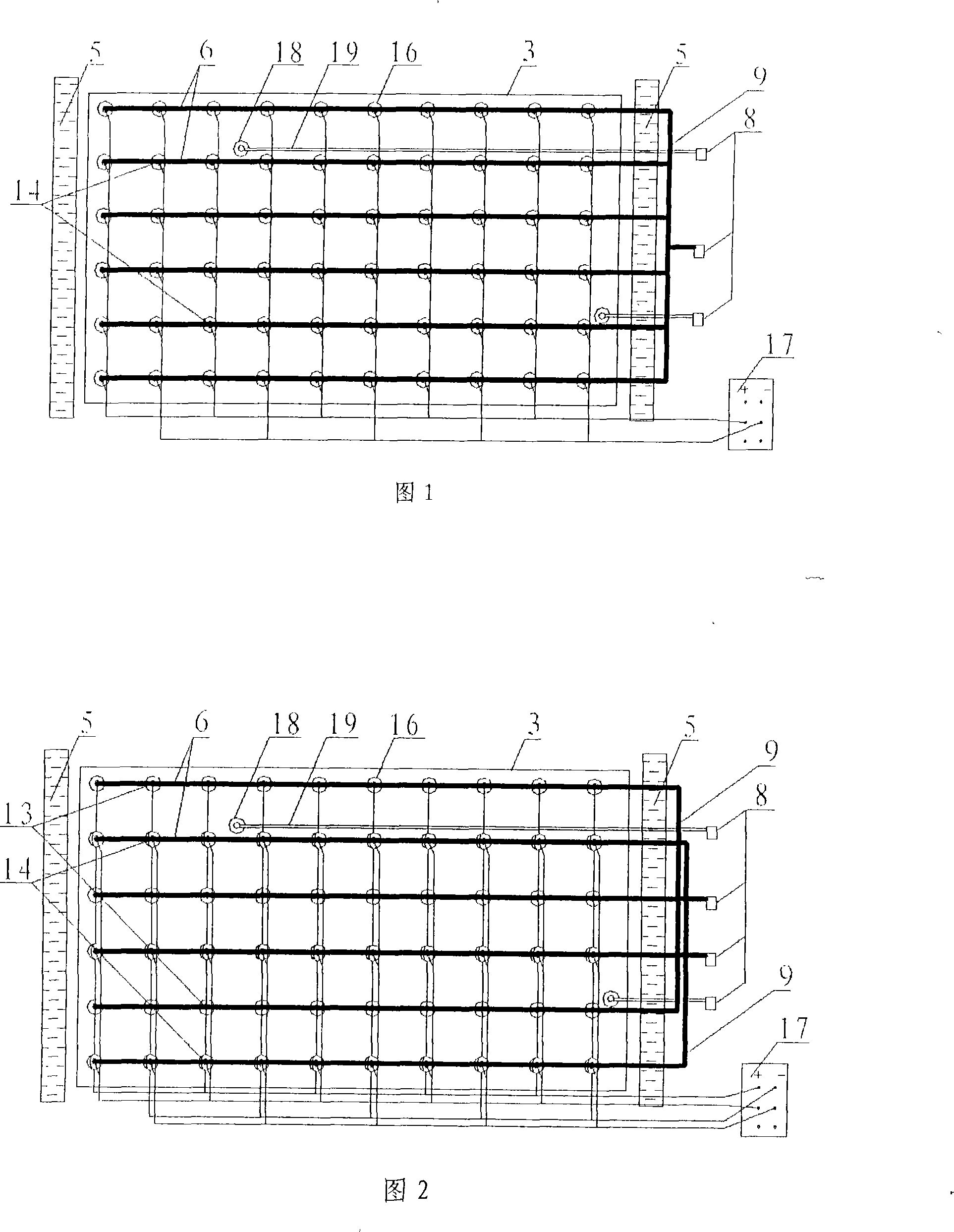

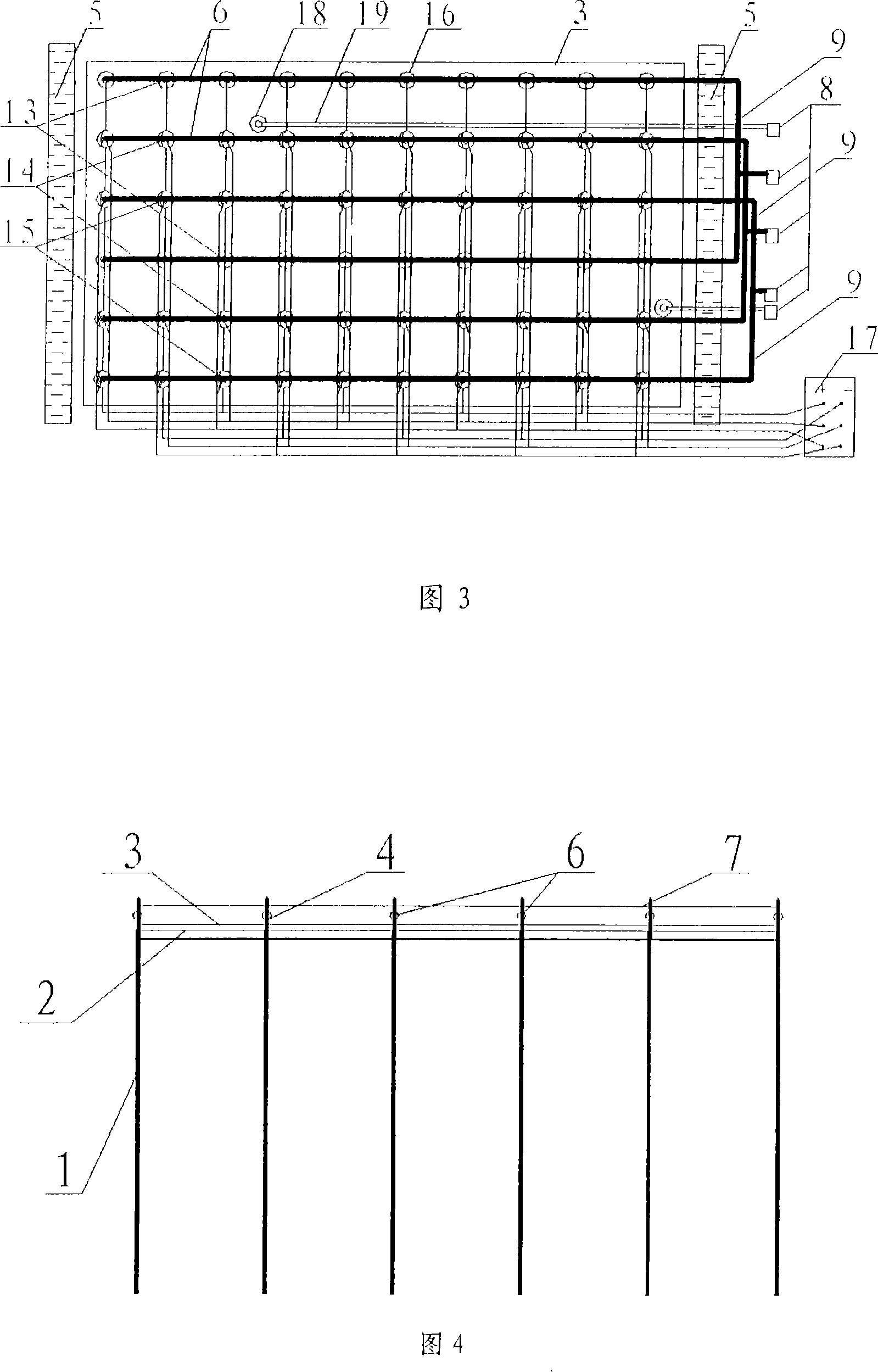

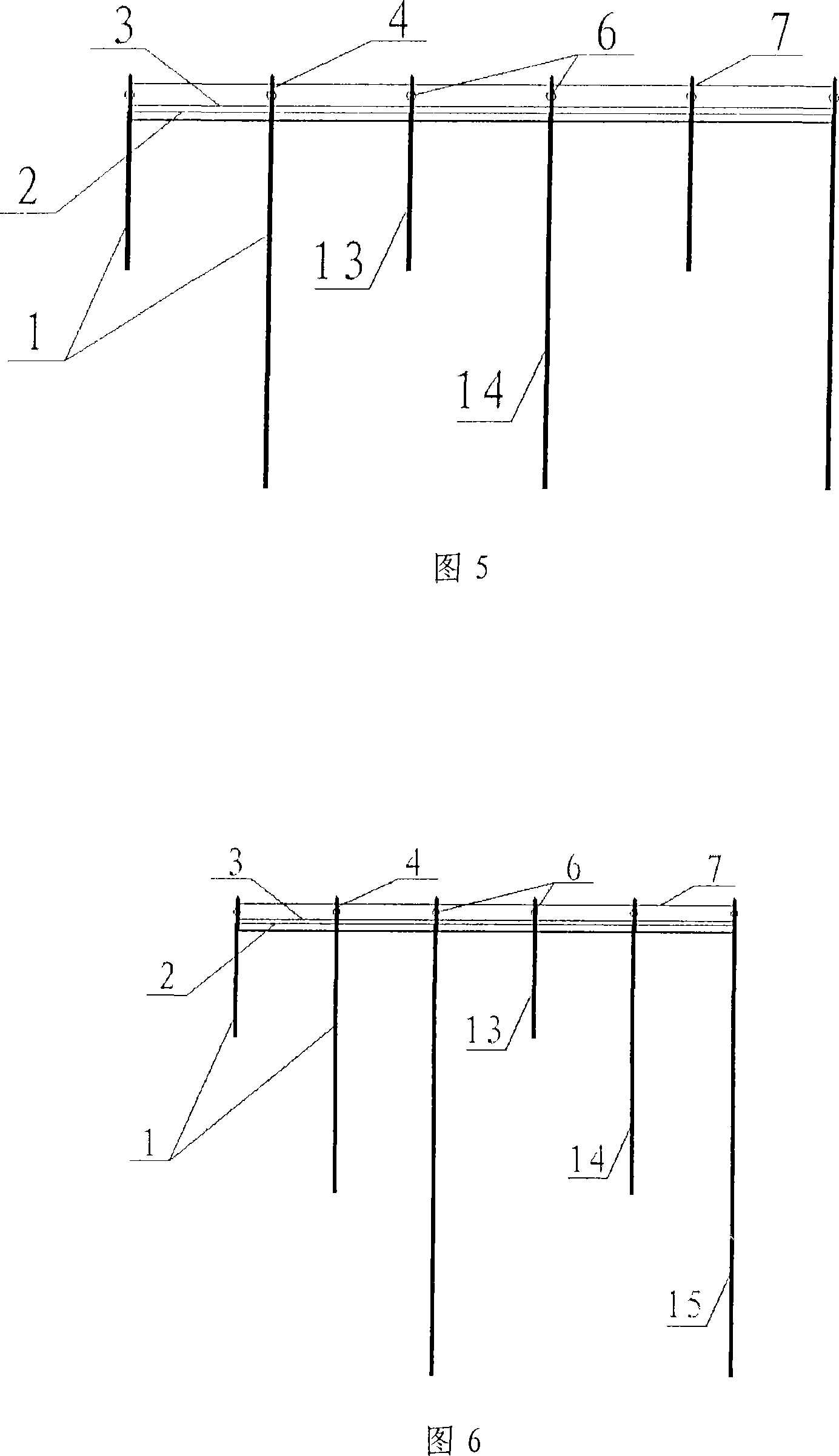

[0102] Embodiment 1: Referring to accompanying drawings 3, 6, 7 and 8,

[0103] At a test site in Guangdong, the treatment depth is required to be 12m

[0104] 1. Roughly level the site, remove sharp objects, and carry out the construction and lofting of the composite pipe according to the distribution of the mesh on the flat surface. As shown in Figure 8, the mesh spacing is set to 0.5 meters.

[0105] 2. Carry out detailed exploration of small screw drilling in the test area, and drill to a depth of not less than 12 meters below the surface. Due to the small area of the test area, 30m×30m grid holes are used for small screw drilling detailed exploration, and well prepared Record. Find out the embedment depth and thickness of various soil layers in the test area, so as to know the soil properties, soil water content, permeability coefficient and endowment status of the test area in time, and draw the drilling profile.

[0106] 3. Prepare mechanical equipment and materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com