Pseudo moving bed type chromatographic separating device

A technology of simulating moving bed and chromatographic separation, which is applied in the field of SMB devices, can solve the problem that the number of metering pumps cannot be reduced, and achieve the effect of precise control and effective reduction of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

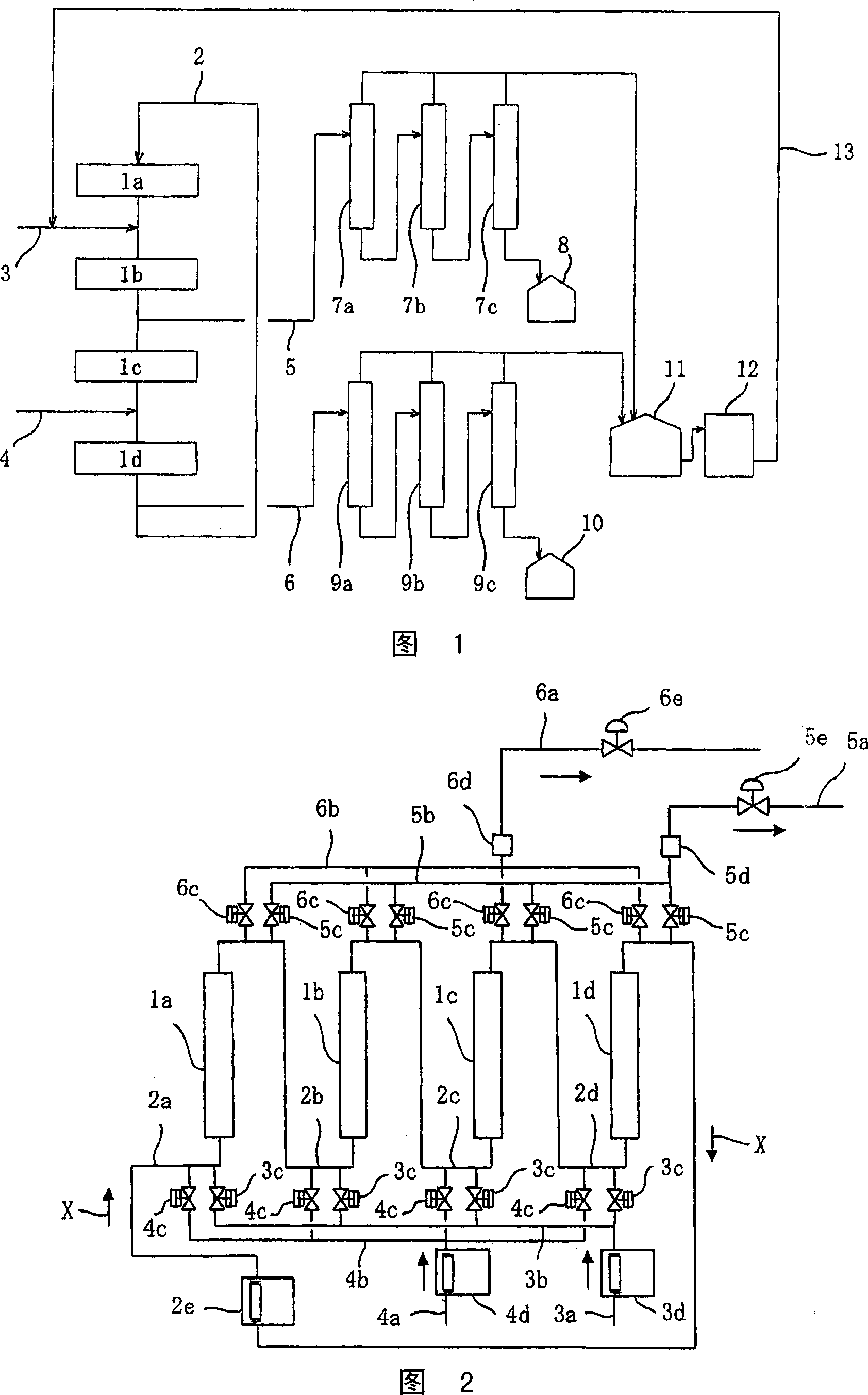

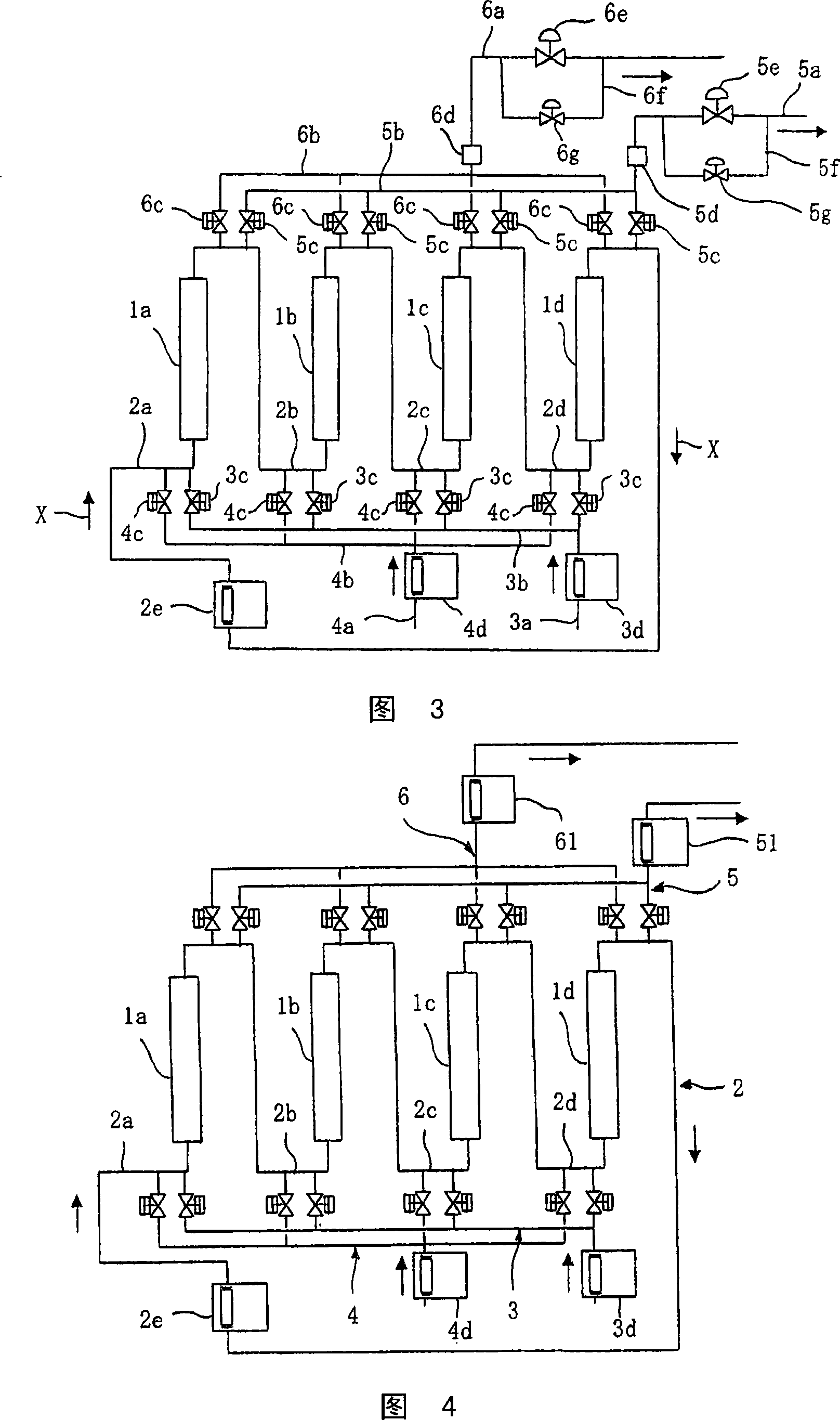

[0099] As shown in FIG. 1 , the SMB apparatus of the present embodiment includes an annular flow path 2 formed by connecting four columns 1 a to 1 d in series, a first flow for supplying a mobile phase connected to the annular flow path 2 . 3, the second flow path 4 connected to the annular flow path 2 for supplying the sample, the third flow path 5 connected to the annular flow path 2 for discharging the mobile phase from the annular flow path 2 Three evaporators 7a to 7c connected in series with the fourth flow path 6 so that the mobile phase in the third flow path 5 is concentrated in the third flow path 5, for receiving the bottom liquid of the evaporator 7c storage tank 8, three evaporators 9a to 9c that are connected in series so that the mobile phase in the fourth flow path 6 is concentrated in the fourth flow path 6, and are used to receive the storage of the bottom effluent of the evaporator 9c A tank 10, a collection tank 11 connected to each top portion of the evapo...

no. 2 example

[0129] As shown in FIG. 3, in addition to the SMB device of the first embodiment, the SMB device of this embodiment further includes bypass pipes 5f and 6f and bypass flow rate control valves 5g and 6g.

[0130] The bypass pipe 5f is a pipe connecting the main pipe 5a between the regulator 5d and the flow rate control valve 5e to the main pipe 5a downstream of the flow rate control valve 5e, which is a bypass flow path in the present invention. The bypass flow rate control valve 5g is a valve that opens / closes the bypass pipe 5f, and the bypass flow rate control valve is a bypass flow rate regulator in the present invention. The bypass flow rate control valve 5g is designed, for example, as a valve whose opening degree can be adjusted more precisely than the flow rate control valve 5e. Examples of the combination of the flow rate control valve 5e and the bypass flow rate control valve 5g include a combination of a ball valve and a needle valve.

[0131] Further, the bypass pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com