Laminate for name plate preparation which can prevent fluctuation in reflected light

A laminated body and nameplate technology, applied to layered products, metal layered products, instruments, etc., can solve the problems of reduced productivity, difficult production, increased number of processes, etc., and achieve good yield, easy width, and number of processes little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

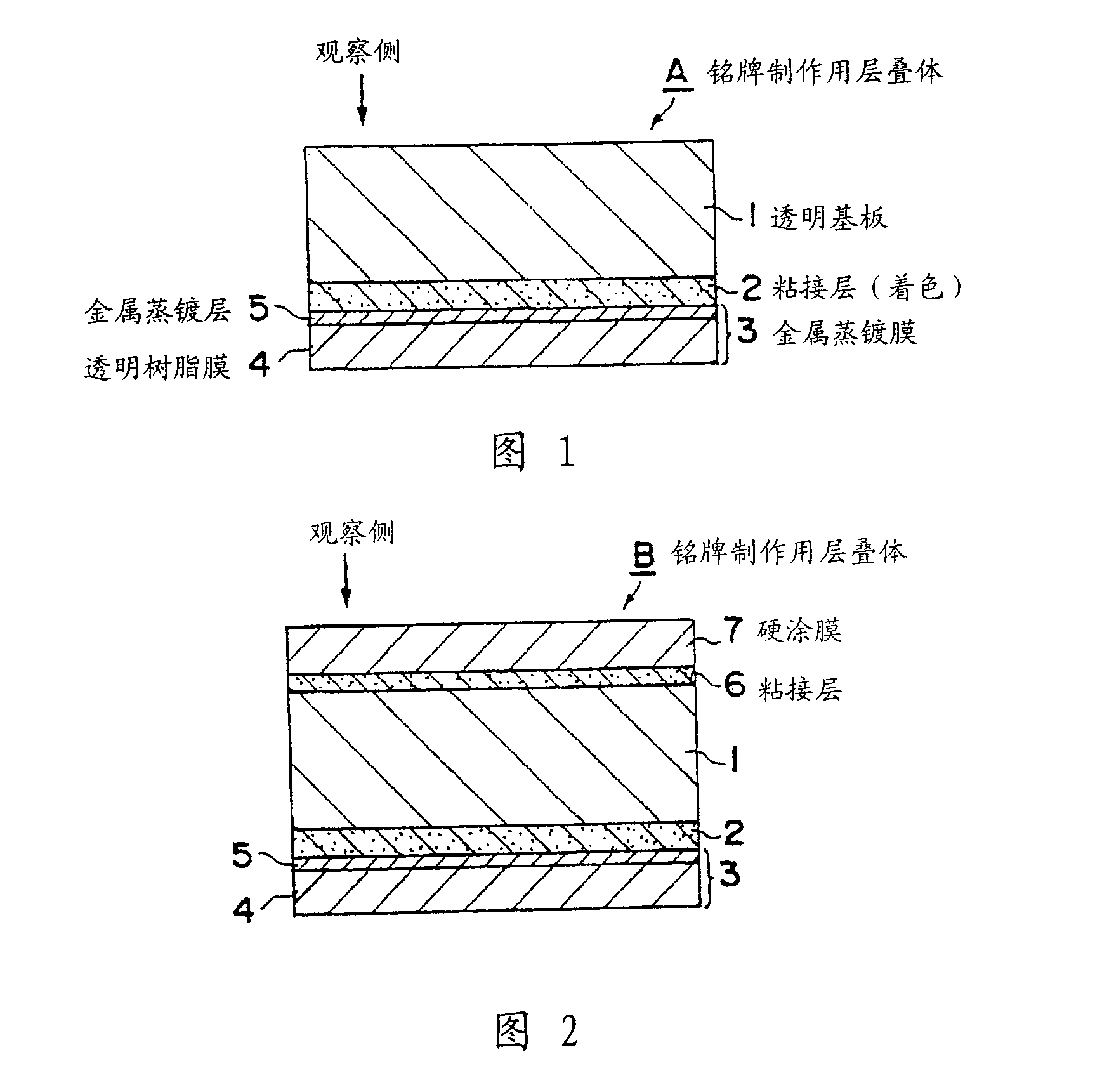

[0038] As a first embodiment, as shown in FIG. 1 , an adhesive layer 2 is sequentially stacked on the back side of a transparent substrate 1 (the back side seen from the observation side, that is, the side opposite to the observation side, that is, the front side). A laminated body A for producing a nameplate having a laminated structure constituted by the metal vapor-deposited film 3 will be described.

[0039] (transparent substrate 1)

[0040] The transparent substrate 1 is not particularly limited as long as it is a transparent and flat plate, and its shape and material are not particularly limited. However, it is preferably made of a transparent resin that can achieve weight reduction or thinning. Specifically, polymethyl methacrylate (PMMA) resin, polycarbonate (PC) resin, methyl methacrylate-styrene copolymer resin (MS resin), polyarylate resin, polysulfone resin, polyether A transparent substrate mainly composed of at least one of sulfone resin, norbornene-based resin...

no. 2 approach

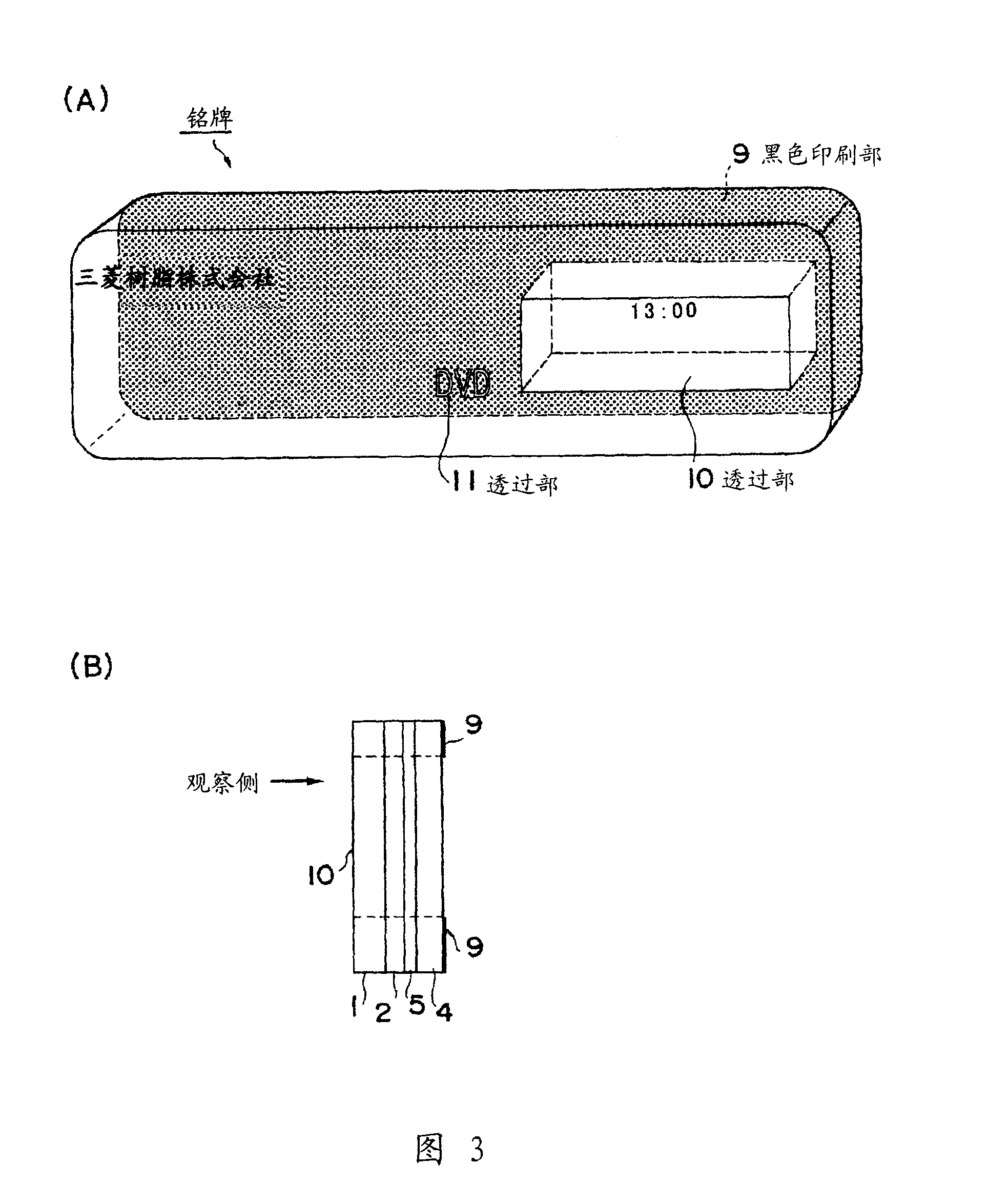

[0086] As a second embodiment, as shown in FIG. 2 , an adhesive layer 2 and a metal vapor-deposited film 3 are sequentially laminated on the back side of a transparent substrate 1 , and a hard coat film 7 is laminated on the front side of the transparent substrate 1 via an adhesive layer 6 . The laminated body B for making a nameplate with a laminated structure is described, that is, the laminated body for making a nameplate having a laminated structure in which a hard coat film 7 is laminated via an adhesive layer 6 on the surface side of the laminated body A for nameplate making is described. Body B will be described.

[0087] The transparent substrate 1, the adhesive layer 2, and the vapor-deposited metal film 3 are the same as those of the above-mentioned laminated body A for producing a nameplate. In addition, the same adhesive layer as the adhesive layer 2 may be used for the adhesive layer 6 .

[0088] In addition, when adding a coloring agent to the adhesive layer, it...

no. 3 approach

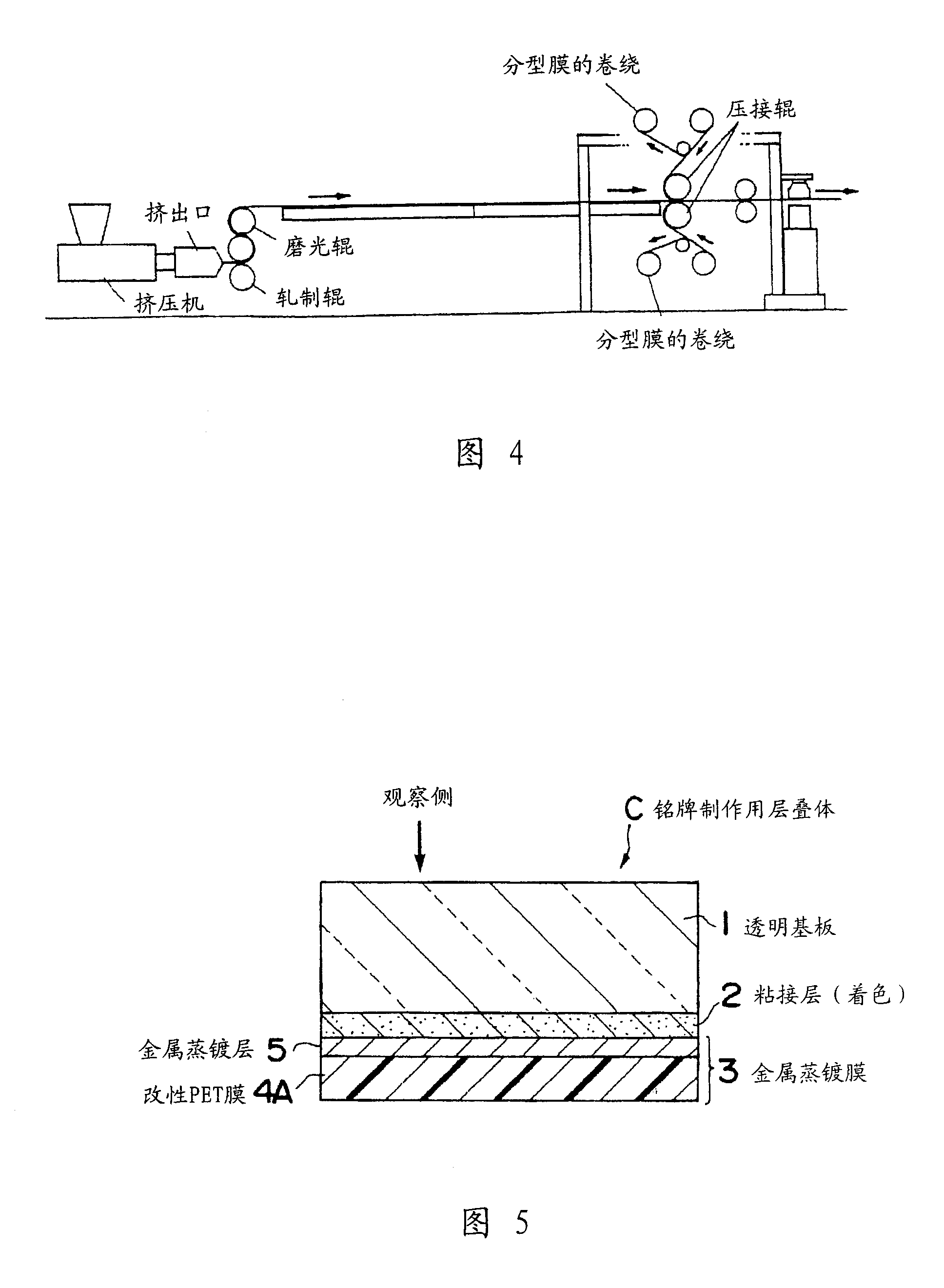

[0110]As shown in Fig. 5 and Fig. 6, the laminated body C for making a nameplate as the third embodiment has a transparent substrate 1 made of synthetic resin on the back side (the back side seen from the observation side, that is, the same side as the observation side). The side opposite to the surface side) is a nameplate-making laminate having a laminated structure in which an adhesive layer 2 and a metal vapor-deposition film 3 are sequentially laminated, and a modified PET film 4A is used as a base film of the metal vapor-deposition film 3 .

[0111] (transparent substrate 1)

[0112] As the transparent substrate 1 , a substrate made of synthetic resin among the transparent substrates 1 described in the first embodiment can be used.

[0113] When the transparent substrate 1 is made of synthetic resin, warping in a high-temperature environment becomes a problem. However, in the present embodiment, by using a predetermined modified PET film , can prevent warping under high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com